Method of selecting nitrogen springs for metal mold

A technology of nitrogen springs and molds, which is applied in the direction of forming tools, manufacturing tools, gas shock absorbers, etc., can solve the problems of large mold space, small initial force, and parts that cannot be lined up, so as to reduce production costs, smooth pressure changes, and The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

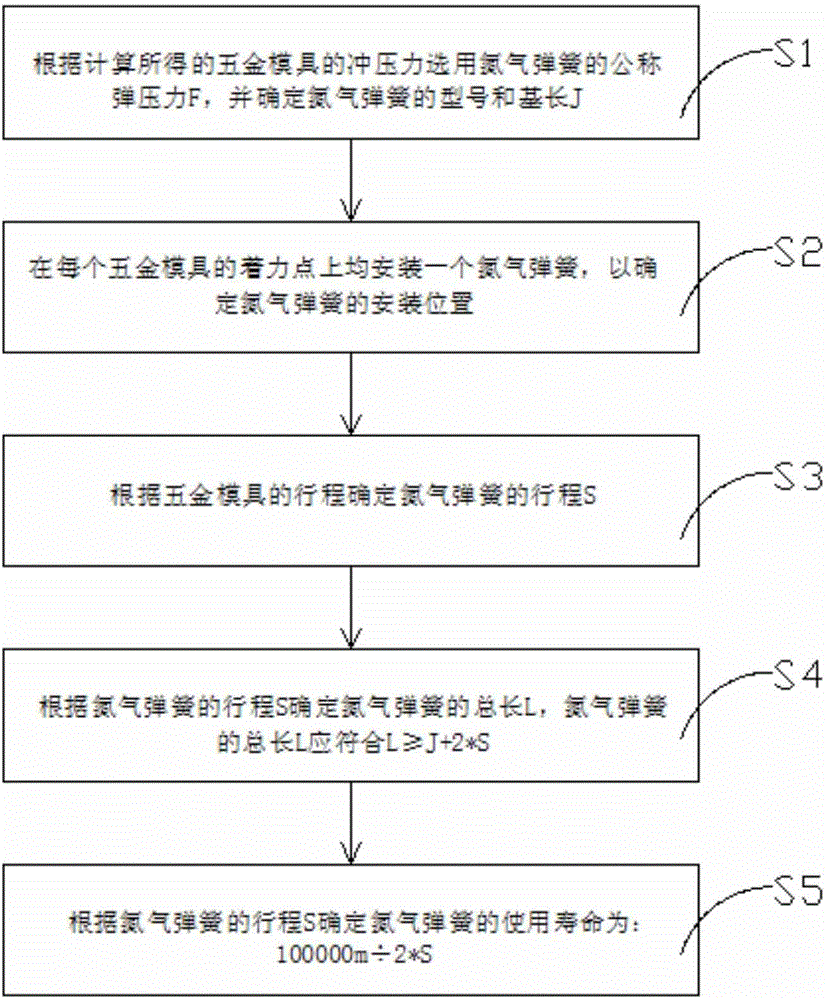

[0019] refer to figure 1 As shown, the present invention provides a method for selecting a nitrogen spring in a metal mold, the method comprising the following steps:

[0020] The first step is to select the nominal elastic force F of the nitrogen spring according to the stamping force of the metal mold obtained from the calculation, and determine the model and base length J of the nitrogen spring; because after the mold is worn, there will be gap changes, the cutting edge will become blunt and other processes The change of parameters, the inconsistency of the mold thickness and the deformation resistance of the mold plate will cause the change of the deformation resistance of the workpiece, so there should be room for the deformation resistance in the design. When the nitrogen spring is inflated, the high-pressure gas will inevitably have th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com