A device for refining metal solidification structure by pulse current

A technology of metal solidification and pulse current, which is applied in the field of metal material processing to achieve the effect of refining grains, improving quality and optimizing processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

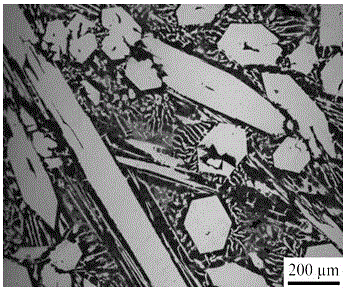

Embodiment 1

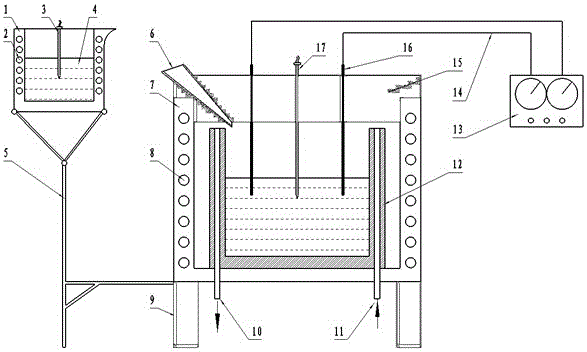

[0023] The device for refining metal solidification structure with pulse current according to this embodiment includes a furnace 1, a heating coil I2, a thermocouple I3, a support I5, a runner 6, a holding furnace 7, a heating coil II8, a support II9, and a crystallizer 12 , high-voltage pulse power supply 13, compensation wire 14, heat-insulating asbestos 15, electrode 16, thermocouple II 17, support I5 is connected with support II 9, and is used to support the whole device; There is a heating coil I2, and a thermocouple I3 is hung on the top of the furnace 1 and extends into the interior of the furnace 1; Thermal asbestos 15; crystallizer 12 is placed in holding furnace 7, runner 6 passes through heat insulating asbestos 15 and is aligned with crystallizer 12; electrode 16 and thermocouple II 17 pass through heat insulating asbestos 15 and extend into crystallizer 12; high voltage pulse The power supply 13 is connected to the electrode 16 through the compensation wire 14, su...

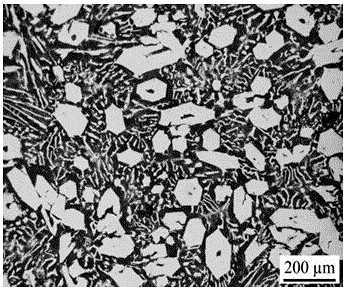

Embodiment 2

[0030]The device for refining metal solidification structure with pulse current according to this embodiment includes a furnace 1, a heating coil I2, a thermocouple I3, a support I5, a runner 6, a holding furnace 7, a heating coil II8, a support II9, and a crystallizer 12 , high-voltage pulse power supply 13, compensation wire 14, heat-insulating asbestos 15, electrode 16, thermocouple II 17, support I5 is connected with support II 9, and is used to support the whole device; There is a heating coil I2, and a thermocouple I3 is hung on the top of the furnace 1 and extends into the interior of the furnace 1; Thermal asbestos 15; crystallizer 12 is placed in holding furnace 7, runner 6 passes through heat insulating asbestos 15 and is aligned with crystallizer 12; electrode 16 and thermocouple II 17 pass through heat insulating asbestos 15 and extend into crystallizer 12; high voltage pulse The power supply 13 is connected to the electrode 16 through the compensation wire 14, suc...

Embodiment 3

[0038] The device for refining metal solidification structure with pulse current according to this embodiment includes a furnace 1, a heating coil I2, a thermocouple I3, a support I5, a runner 6, a holding furnace 7, a heating coil II8, a support II9, and a crystallizer 12 , high-voltage pulse power supply 13, compensation wire 14, heat-insulating asbestos 15, electrode 16, thermocouple II 17, support I5 is connected with support II 9, and is used to support the whole device; There is a heating coil I2, and a thermocouple I3 is hung on the top of the furnace 1 and extends into the interior of the furnace 1; Thermal asbestos 15; crystallizer 12 is placed in holding furnace 7, runner 6 passes through heat insulating asbestos 15 and is aligned with crystallizer 12; electrode 16 and thermocouple II 17 pass through heat insulating asbestos 15 and extend into crystallizer 12; high voltage pulse The power supply 13 is connected to the electrode 16 through the compensation wire 14, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com