Liquid nitrogen wash molecular sieve pre-cooling device

A molecular sieve and liquid nitrogen washing technology, which is used in household refrigeration equipment, using liquid contact hydrogen separation, hydrogen separation and other directions, can solve the problems of shortening the start-up time of the liquid nitrogen washing process, high gas temperature at the molecular sieve outlet, and reducing effective gas venting, etc. Achieve the effect of saving driving time, simple structure and protecting molecular sieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

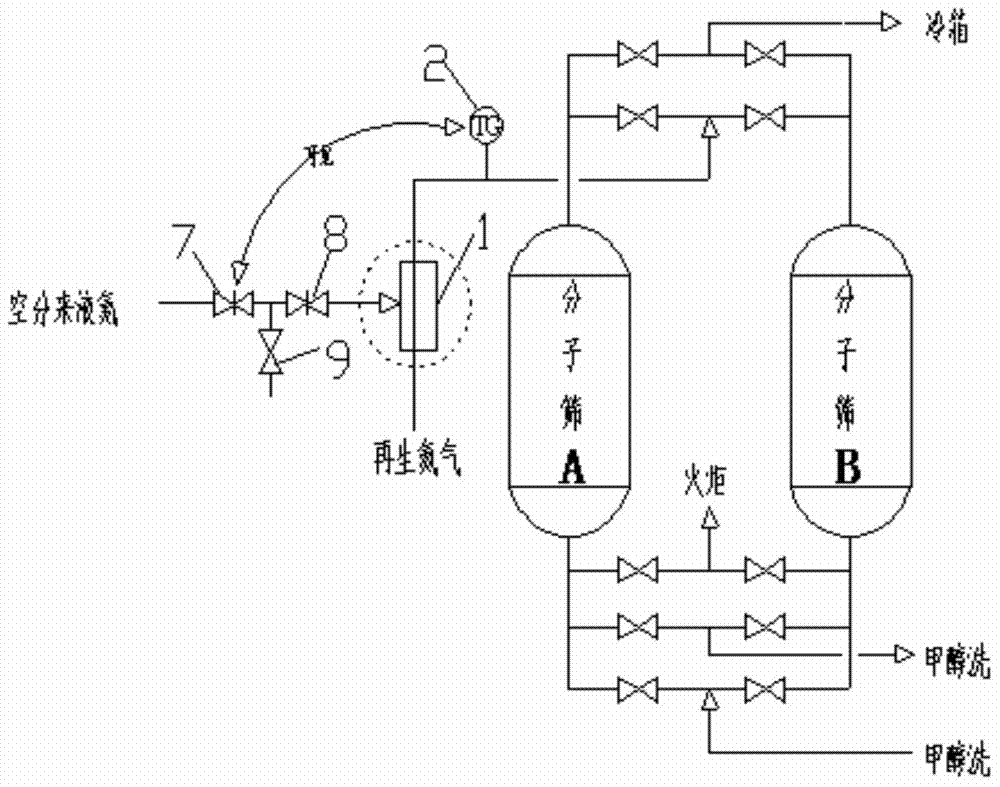

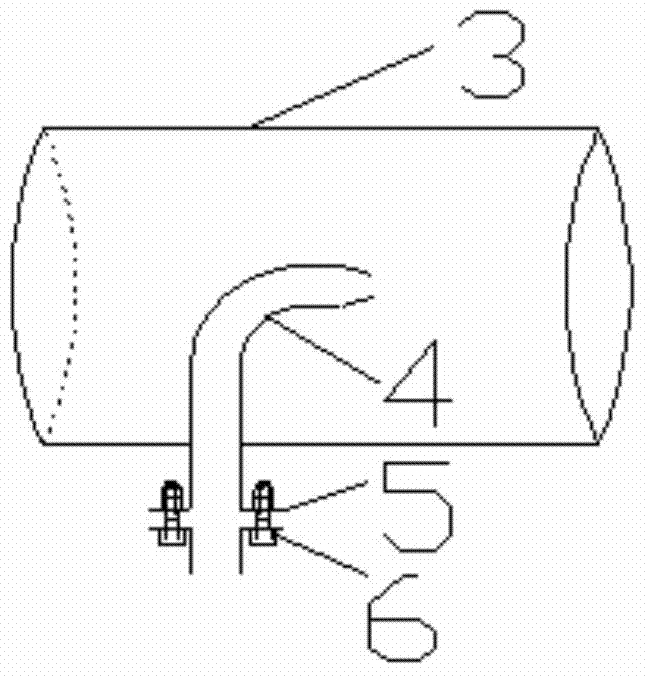

[0013] see figure 1 , 2 , a liquid nitrogen washing molecular sieve precooling device, including a pipeline liquid nitrogen atomization device 1 and a regeneration gas temperature adjustment device, the pipeline liquid nitrogen atomization device includes a cylinder 3 and a liquid nitrogen nozzle 4, and the cylinder 3 is fixed Welded on the pipeline of regeneration gas entering the molecular sieve, the front end of the liquid nitrogen nozzle 4 is located in the cylinder 3, and the rear end of the liquid nitrogen nozzle 4 passes through the side of the cylinder 3 and is connected with a liquid nitrogen pipeline; the regeneration gas temperature adjustment device Including the first and second liquid nitrogen flow control valves 7 and 8 and the on-site thermometer 2, the first and second liquid nitrogen flow control valves 7 and 8 are respectively installed on the liquid nitrogen pipeline, the first and second liquid nitrogen flow control valves 7 and 8 The liquid nitrogen pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com