An aluminum strip shearing unit for a transformer

A technology for shearing units and transformers, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of surface scratches, bumps, and high scrap rate of aluminum strips, improve edge quality, and facilitate bundling and conveying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

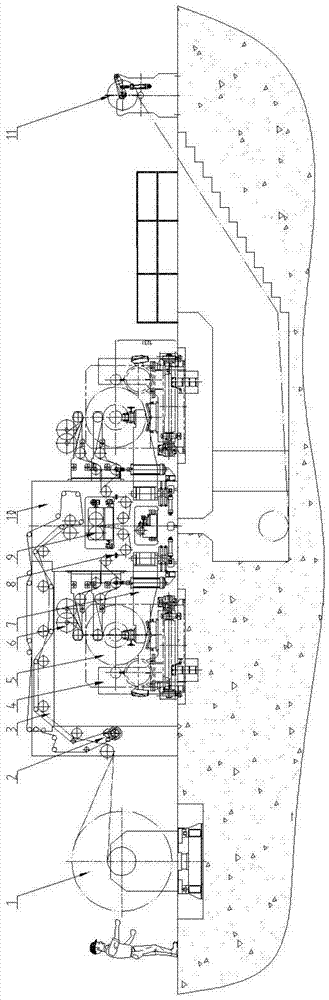

[0029] Refer to attached figure 1 , an aluminum strip shearing unit for a transformer, mainly composed of an uncoiler 1, an automatic belt threading device 2, an upper bridge device 3, an unloading trolley 4, a coiler 5, a backing paper clamping device 6, and a coiling auxiliary support 7 , Deburring and chamfering device 8, shearing mechanism 9, unit host 10, and waste edge rolling device 11.

[0030] The uncoiler 1 is located on the far left side of the unit and is an independent unit. It adopts a cone-shaped structure and is driven by a frequency conversion motor. Online measurement of roll diameter.

[0031] The automatic belt threading device 2 is installed on the upper bridge device 3, and the strip material is transported to the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com