A kind of composite material plate and its manufacturing method and its finished product

A technology of composite materials and manufacturing methods, applied in the field of composite materials, can solve the problems of high production cost and consumption of building templates, achieve performance improvement, prevent serious environmental pollution, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

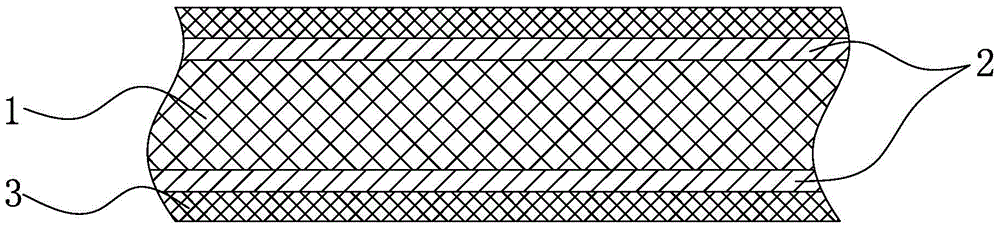

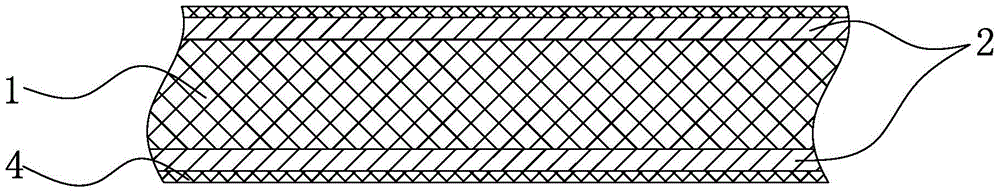

[0057] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -2:

[0058] A composite material plate, including a substrate, the substrate is prepared by putting the following substances in the weight percentage into a mixer and stirring together for 8-10 minutes, and the temperature during stirring is not more than 115 degrees:

[0059] Divided into two formulations:

[0060] Recipe 1:

[0061] Industrial waste PVC, PE and PU materials 60.0%-69.0%;

[0062] Plasticizer 3.4%-7.0%;

[0063] Heat stabilizer 1.0%-2.0%;

[0064] Inorganic filler 26.0%-29.0%;

[0065] Lubricant 0.5%-1.0%;

[0066] Antioxidant 0.1%-1.0%.

[0067] Recipe 2:

[0068] Industrial waste PVC, PE and PU materials 35.2%-52.6%;

[0069] Wood flour 25.0%-30.0%

[0070] Plasticizer 3.4%-7.0%;

[0071] Heat stabilizer 1.0%-2.0%;

[0072] Inorganic filler 15.0%-18.0%;

[0073] Internal and external lubricant 0.8%-1.8%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com