Aloe fiber, milk protein fiber and special-shaped-section polyester fiber blended yarn and production technology

A polyester fiber and special-shaped cross-section technology is applied in the field of multi-fiber blended yarn and its production process, which can solve the problems of small coverage, poor adhesion, easy pilling, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

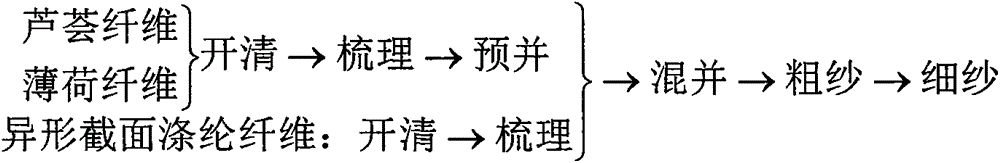

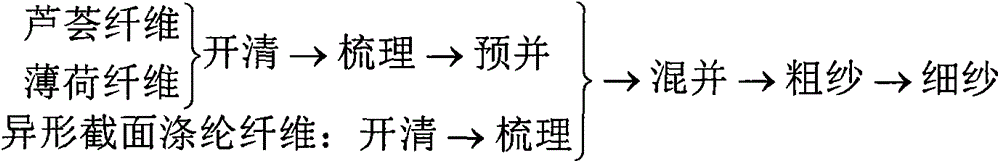

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

[0020] Raw material preparation: aloe fiber 1.33dtex×38mm; bovine albumin fiber 1.33dtex×38mm; cross-section polyester fiber 1.33dtex×38mm

[0021] Spinning specifications: aloe fiber / bovine albumin fiber / cross-section polyester fiber: 20% / 20% / 60%,

[0022] Yarn density: 16.8tex

[0023] a. Start cleaning process

[0024] The beater speed of the catching machine is 850r / min, and the beater extends out the ribs by 2mm; the distance between the corner nail curtain and the cotton pressing curtain of the SFA035C mixed cotton opening machine is 20mm, and the average cotton beater speed is 140r / min. The parallel beater speed I is 260r / min , II is 330r / min, the speed of the nose beater is 450r / min, the beater speed of the FA106A porcupine opener is 460r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| coefficient of variation of linear density | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com