Cigarette paper with tobacco leaf fragments and tobacco leaf powder attached to the surface and its preparation method

A technology of tobacco leaf fragments and tobacco leaf powder, which is applied in wrapping paper, wrapping paper, transportation and packaging, etc. It can solve the problems of unstable tobacco materials and limited amount of addition, increase anti-counterfeiting functions, improve smoking quality, and eliminate counterfeiting and shoddy products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] By weight, 5 parts of 20-order tobacco leaf fragments, 5 parts of 150-order tobacco leaf powder, 1 part of tobacco water extract extract, 2 parts of modified starch, 1 part of cellulose, and 86 g of purified water were used to form a mixed slurry, which was homogenized. Homogenized by a quality machine to obtain a spray slurry;

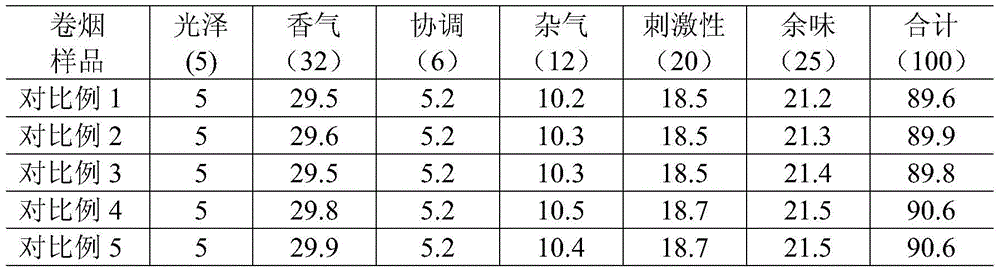

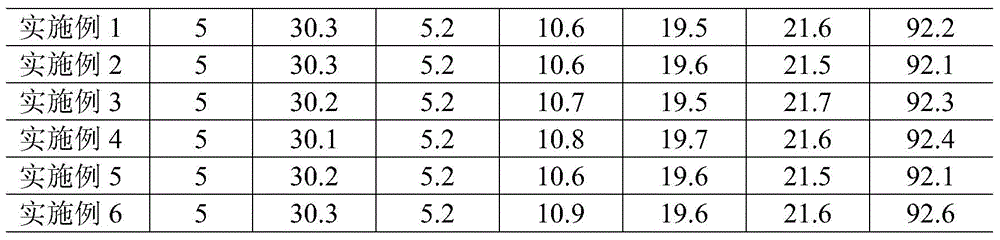

[0028] Spraying method using compressed air atomization, for 20g / m 2 Cigarette paper is sprayed, and the spraying amount is 70g / m 2 , and then dried in the way of hot air penetration, and the dried cigarette paper is finished cigarette paper after being rolled, shaped, wound and cut. After tipping the cigarette, the quality of smoking is significantly improved, see Table 1 for details.

[0029] After testing, the spraying amount of the spraying slurry reaches 22% of the dry weight of the cigarette paper.

Embodiment 2

[0031] By weight, 6 parts of 30-order tobacco leaf fragments, 2 parts of 120-order tobacco leaf powder, 1.5 parts of tobacco ethanol extract, 3 parts of modified starch, 2 parts of cellulose, and 86.5 parts of purified water were used to form a mixed slurry, which was homogenized Machine homogeneity, as a spray slurry.

[0032] Use the spraying method of compressed air atomization to spray 22g / m2 cigarette paper with a spraying amount of 75g / m2, and then dry it by hot air penetration. It is the finished cigarette paper. After tipping the cigarette, the quality of smoking is significantly improved, see Table 1 for details.

[0033] After testing, the spraying amount of the spraying slurry reaches 23% of the dry weight of the cigarette paper.

Embodiment 3

[0035] By weight, 6 parts of 40-order tobacco leaf fragments, 2 parts of 160-order tobacco leaf powder, 4 parts of tobacco water extract extract, 4 parts of modified starch, 2.5 parts of cellulose, and 81.5 parts of purified water were used to form a mixed slurry, which was homogenized. Homogenized by a homogenizer, used as a spraying slurry.

[0036] Use the spraying method of compressed air atomization to spray 17g / m2 cigarette paper with a spraying amount of 80g / m2, and then dry it by hot air penetration. It is the finished cigarette paper. After tipping the cigarette, the quality of smoking is significantly improved, see Table 1 for details.

[0037] After testing, the spraying amount of the spraying slurry reaches 21% of the dry weight of the cigarette paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com