Tool for measuring shrinkage rate of plastic part

A technology for measuring tools and plastic parts, applied in the field of measuring tools, can solve the problems of large site space impact, insufficient production capacity, CMM measuring instrument investment cost and high maintenance cost, etc., to achieve the effect of being easy to carry and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

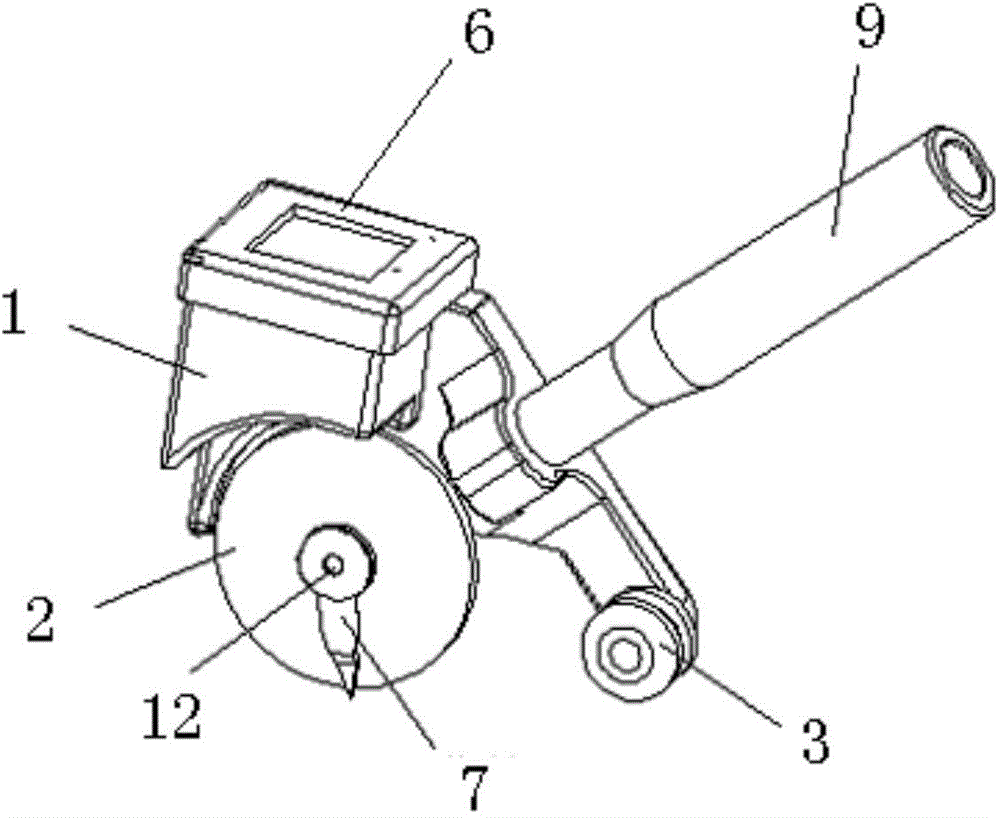

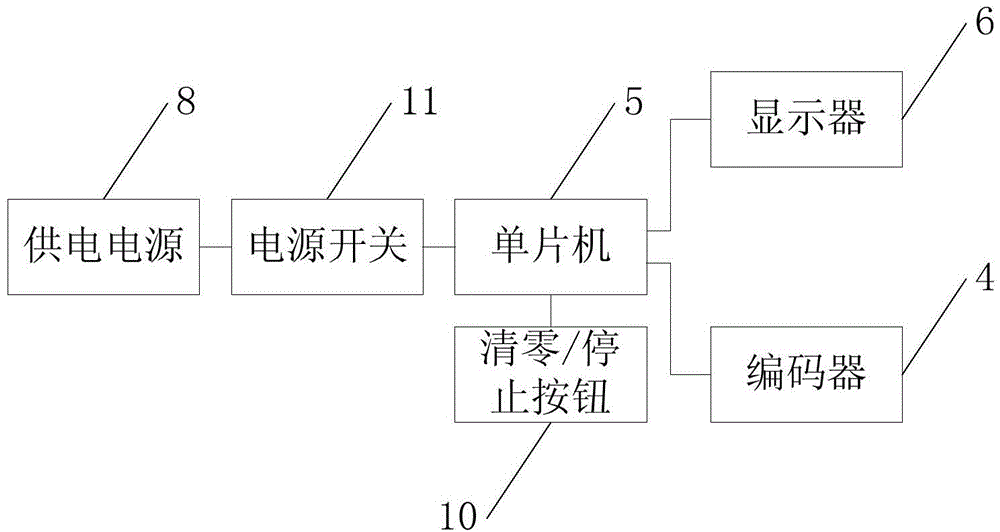

[0030] Such as figure 1 , 2 Shown, the present invention, namely a kind of measuring instrument for measuring the shrinkage of plastic parts, comprises:

[0031] Tool body 1;

[0032] A main roller 2 for contacting with the surface of the plastic part, which is rotatably connected to the tool body 1 around a first rotating shaft 12 provided on the tool body 1;

[0033] An auxiliary roller 3 for contacting with the surface of the plastic part and spaced apart from the main roller 2, which is rotatably connected with the tool body 1 around a second rotating shaft (not shown) arranged on the tool body 1;

[0034] An encoder 4 coaxial with the main roller 2 and fixedly connected, which outputs a corresponding pulse signal as the main roller 2 rotates;

[0035] The single-chip microcomputer 5 arranged on the tool body 1 and connected with the encode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com