Method and device for precisely measuring volume of volume metering pipe

A technology of volumetric measurement and measuring device, which is applied in the direction of volumetric measuring instrument/method, measuring device, liquid/fluid solid measurement, etc. It can solve the problems of high software and hardware requirements, poor precision and accuracy, and small application range, and achieve test Accurate results, exclusion of air bubbles and dirt, and a wide range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

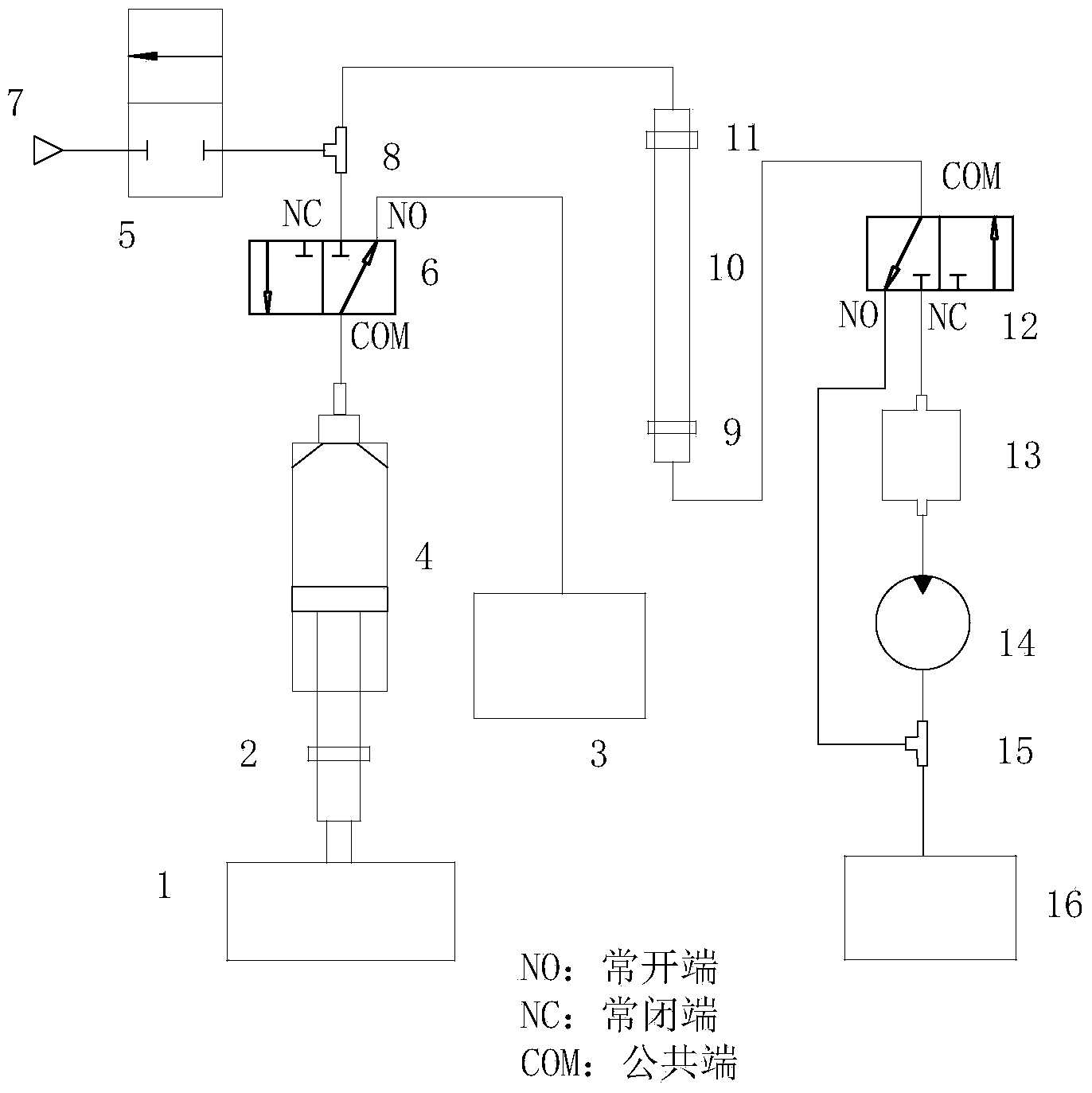

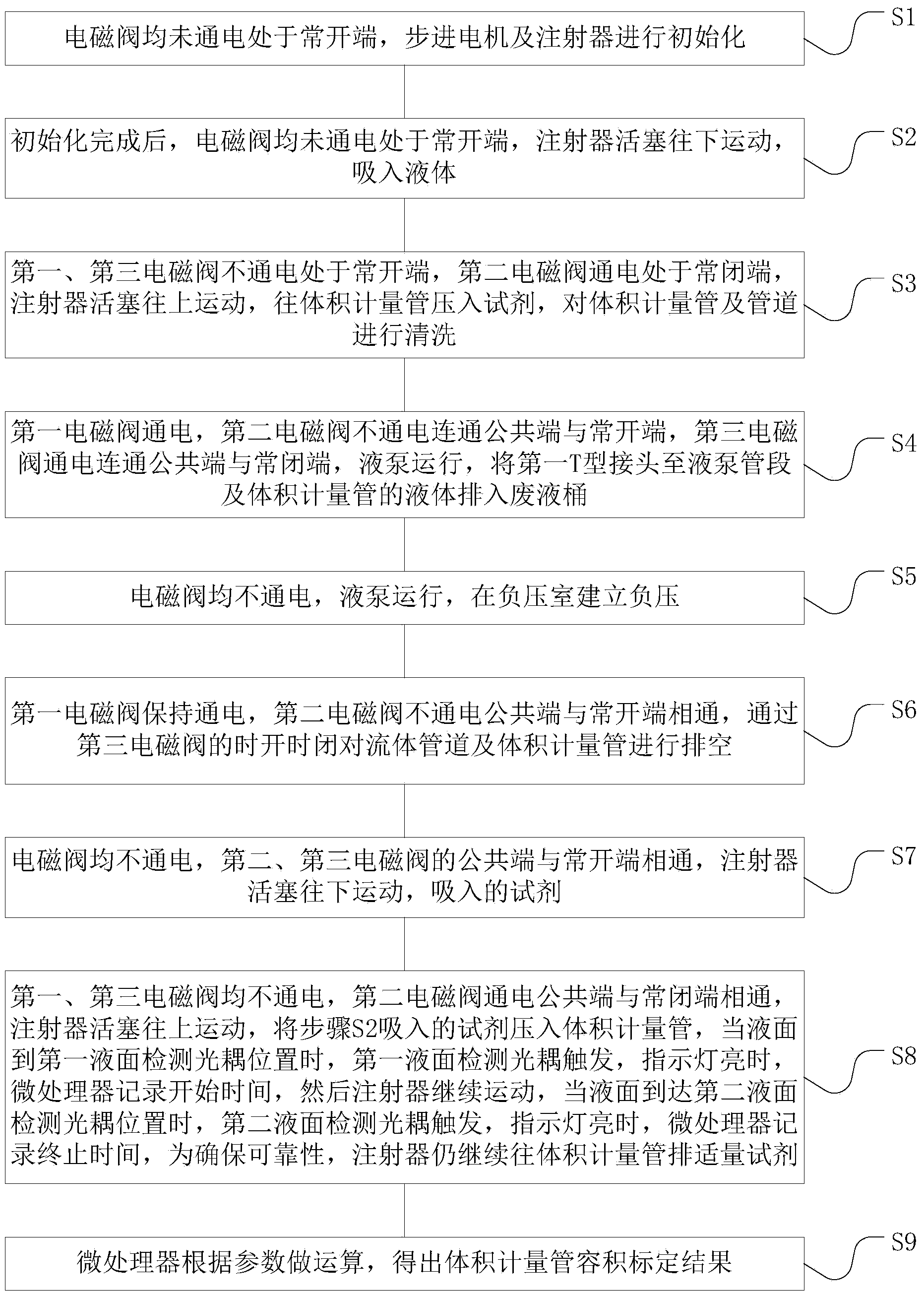

[0048] Such as figure 1 As shown, the device provided in Embodiment 1 uses the stepper motor 1 to convert the rotational motion of the motor rotor into linear motion through the lead screw. The lead screw is rigidly connected with the piston of the syringe 4, so that the piston of the syringe also moves axially in a straight line to absorb or discharge liquid. The stepper motor (with lead screw) and the mechanical structural parts of the syringe machine form the syringe assembly. The injector assembly is equipped with an optocoupler 2 at the initial position of the motor. The initial motor is rigidly connected with the optocoupler and the structure of the injector assembly. The motor is initialized by finding the optocoupler. The initialized motor and syringe can participate in the test at any time.

[0049] The outlet of the syringe 4 is connected to the common port COM of the second solenoid valve 6 . The normally open end NO of the second solenoid valve 6 is connected to ...

Embodiment 2

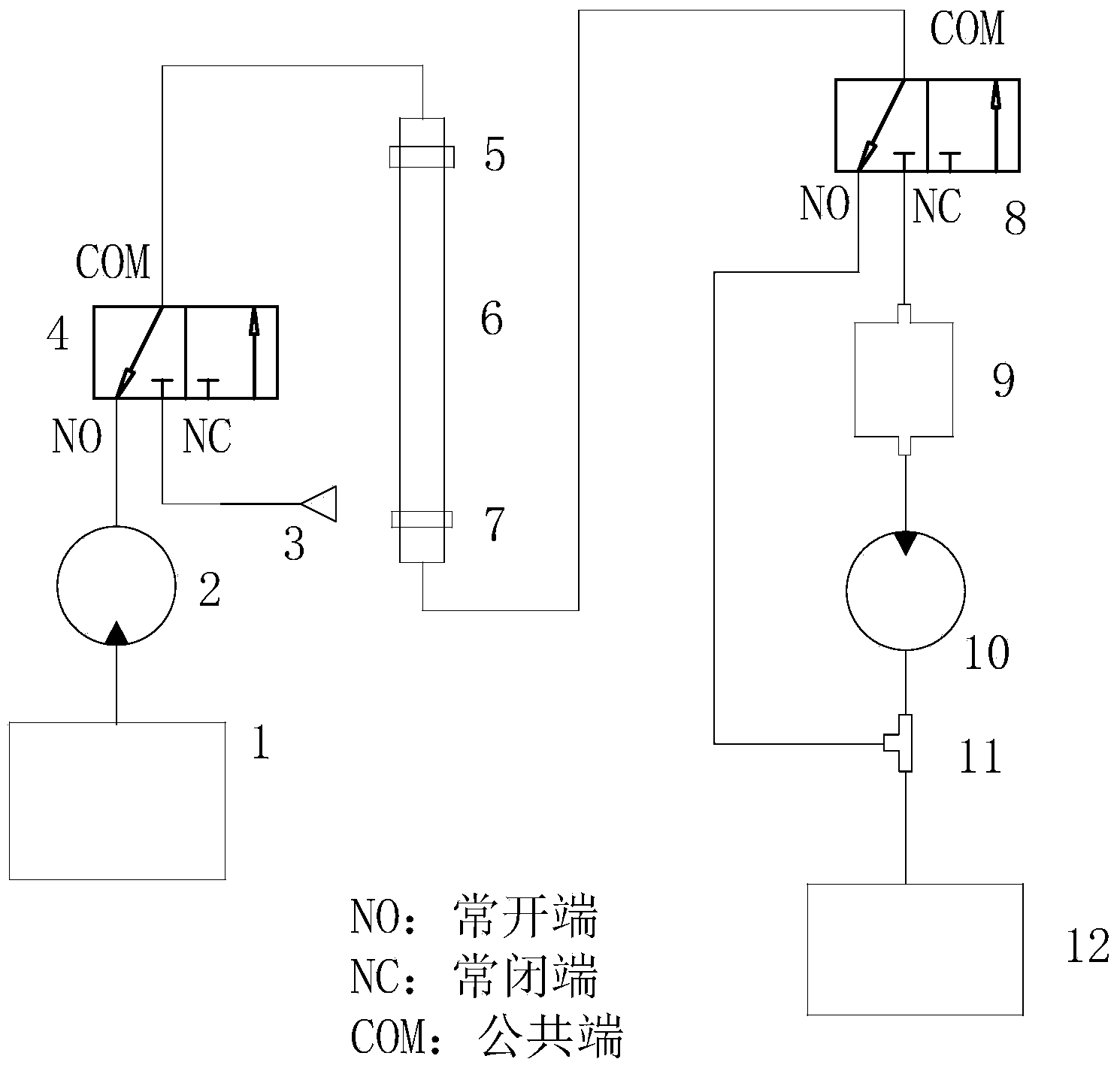

[0071] The high-precision measuring device for the volume of the volume metering tube provided in Example 2 is a micro quantitative liquid pump driven by electricity. Because the outlet pressure of the micro quantitative liquid pump is the sum of the local atmospheric pressure, the pressure lost along the pipeline and the pressure lost locally, Very small, high volumetric efficiency, high quantitative accuracy. The trigger deviation of the liquid level detection optocoupler is ±1ms, and the trigger errors of the first liquid level detection optocoupler and the second liquid level detection optocoupler can cancel each other out, so the error caused by the liquid level detection optocoupler is also very small. Integrating the error of the micro quantitative liquid pump, the error of the liquid level detection optocoupler, etc., the error of the entire calibration system is also very small, and the coefficient of variation (CV value) can reach 0.5%, or even smaller, showing that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com