Fusion product comprehensive protection device for Z-hoop condensation polymerization fission energy pile

A technology of mixing energy and fusion products, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve problems such as incomplete absorption of aerosols, threats to the safety of the first wall, and poor protection of fusion debris, etc., to achieve effective Fusion safety protection function, simple protection measures, and the effect of realizing fusion safety protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

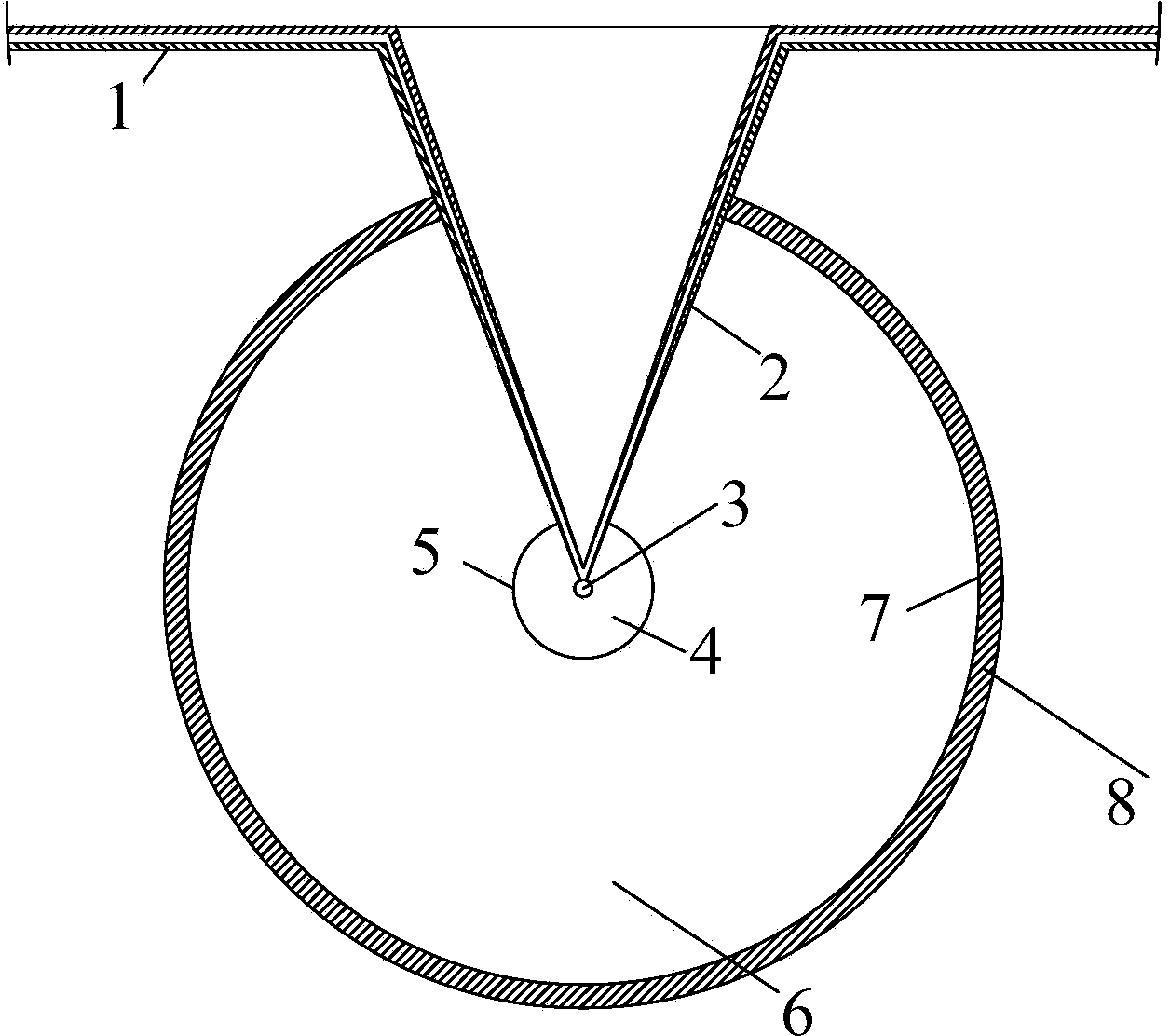

[0054] refer to figure 1 As shown, a comprehensive protection device for a Z-pinch fusion-fission hybrid energy reactor, the Z-pinch fusion-fission hybrid energy reactor is provided with a fusion bullseye 3 and its peripheral plasma-facing first wall 8, including a fusion bullseye 3 From the outside to the first wall 8 facing the plasma, the inner gas atmosphere layer 4, the metal protective cover 5, the outer gas atmosphere layer 6 and the first wall protection layer 7 are arranged in sequence, and the inner gas atmosphere layer 4 is filled with fusion The inner protective gas between the bullseye 3 and the metal shield 5 is formed, and the outer gas atmosphere layer 6 is composed of the outer protective gas filled between the metal shield 5 and the first wall protective layer 7, and the first wall protective layer 7 It is arranged on the inner wall surface of the first wall 8 facing the plasma. The inner protective gas is Ar gas with a pressure of 1000Pa, and the outer prot...

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, the difference is that the inner protective gas is Ar gas with a pressure of 500Pa, and the outer protective gas is Ar gas with a pressure of 500Pa. The metal protective cover is made of Al, with a radius of 50 cm and a wall thickness of 0.25 mm. The protective layer of the first wall is a W-10% Re alloy facing the inner wall surface of the first plasma wall, and the coating thickness is 0.2mm. Under the condition of 1.5GJ fusion energy release, the final protection result is calculated by using the radiation hydrodynamic model calculation program: the radiation energy density on the inner surface of the first wall is about 50J / cm without protection 2 down to 0.015J / cm 2 , peak radiation current power density 7W / cm 2 , the impact strength received by the first wall at the same time is 0.20 MPa, both of which are far less than the safety limit of the first wall; the fusion energy fragments together with the metal p...

Embodiment 3

[0058] This embodiment is basically the same as Embodiment 2, the difference is that the inner protective gas is Ar gas / Al aerosol with a pressure of 100Pa, and the outer protective gas is Ar gas / Al aerosol with a pressure of 250Pa. The metal protective cover is made of Al metal with a radius of 60cm and a wall thickness of 0.2mm. The protective layer of the first wall is a W-10% Re alloy facing the inner wall surface of the first plasma wall, and the coating thickness is 0.2mm. Under the condition of 1.5GJ fusion energy release, the final protection result is calculated by using the radiation hydrodynamic model calculation program: the radiation energy density on the inner surface of the first wall is about 50J / cm without protection 2 down to 0.06J / cm 2 , Peak radiation current power density 42W / cm 2 , the impact strength received by the first wall at the same time is 0.25 MPa, both of which are far less than the safety limit of the first wall; the fusion energy fragments t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com