Fixed-abrasive-grain wire-saw, method for manufacturing same, and method for cutting workpiece using same

A technology for fixing abrasive grains and wire saws, applied in the direction of manufacturing tools, metal sawing equipment, knives of sawing machine devices, etc., can solve problems such as worrying about not being eliminated, and achieve the effect of high-precision cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] Embodiments of the present invention will be described in detail below. However, the present invention is not limited by the following Examples. Here, using a fixed abrasive wire saw manufactured by the present invention and a fixed abrasive wire saw manufactured by a conventional method as a comparative example, blocks were ground and their cutting performances were compared and evaluated.

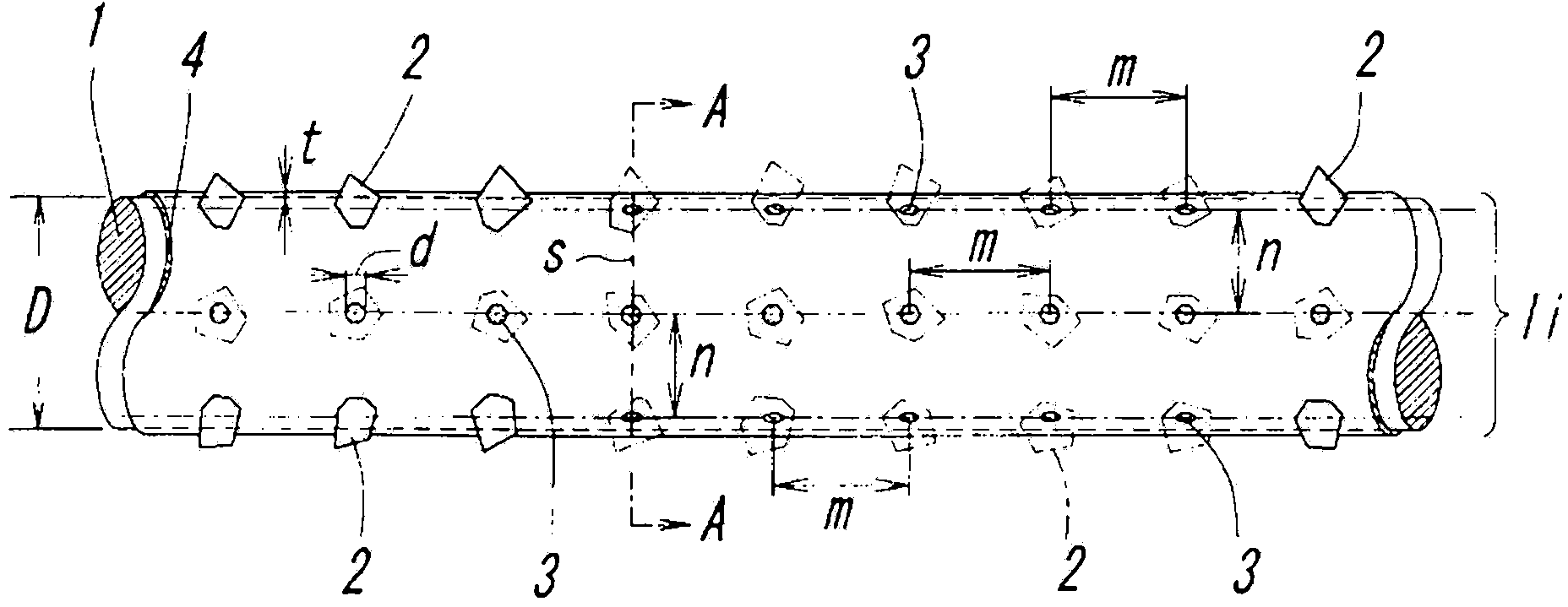

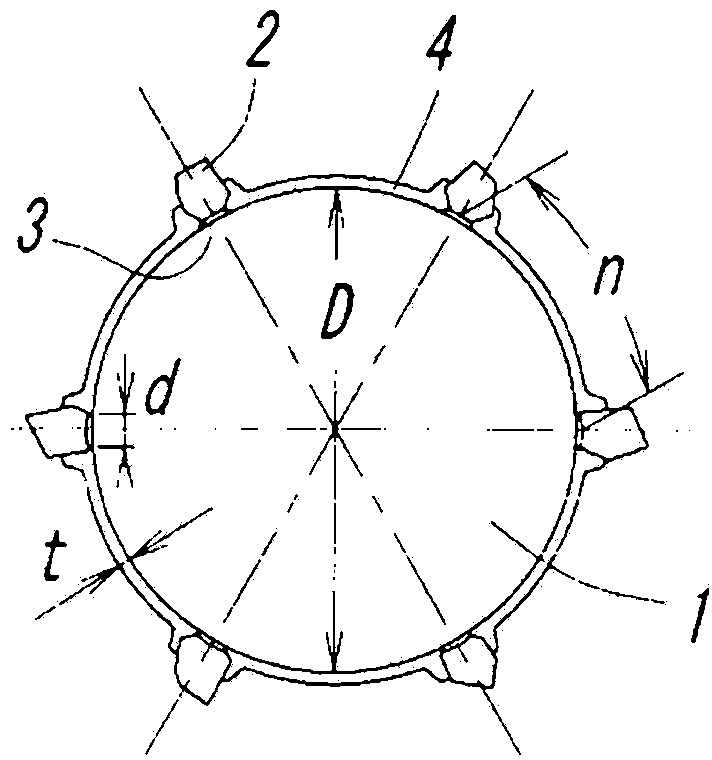

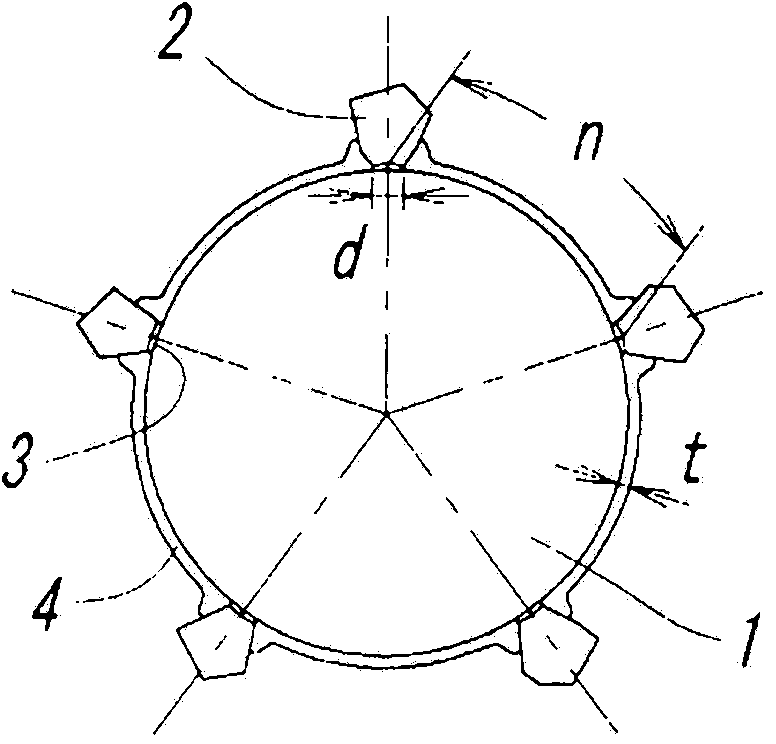

[0077] Here, based on the fixed abrasive wire saw of the present invention, and figure 1 and figure 2 The implementation of is quite, specifically Figure 10 The fixed abrasive wire saw shown, is made of Figure 6-8 In the manufacturing method shown, on the outer peripheral surface of the core wire, the adhesive layer array formed by arranging a plurality of dot-shaped adhesive layers in a straight line at a certain interval of 200 μm is arranged in the circumferential direction of the core wire. A wire saw with fixed abrasives is produced by arranging 6 rows at equal angular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com