Cost-effective single crystal multi-stake actuator and method of manufacture

一种致动器、单晶的技术,应用在压电/电致伸缩器件的制造/组装、压电器件/电致伸缩器件、压电/电致伸缩/磁致伸缩器件等方向,能够解决单晶环及单晶管异向、高生产成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

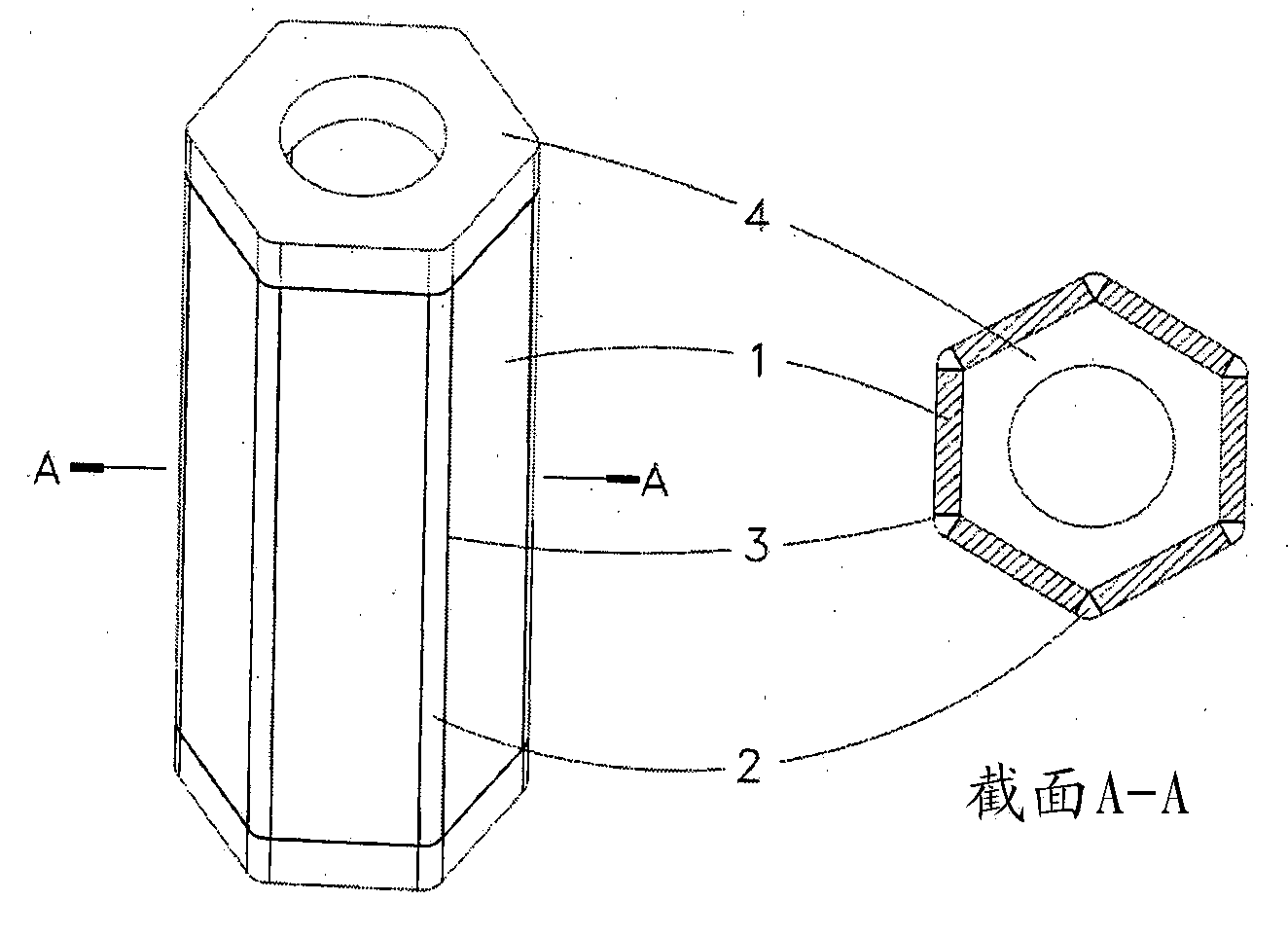

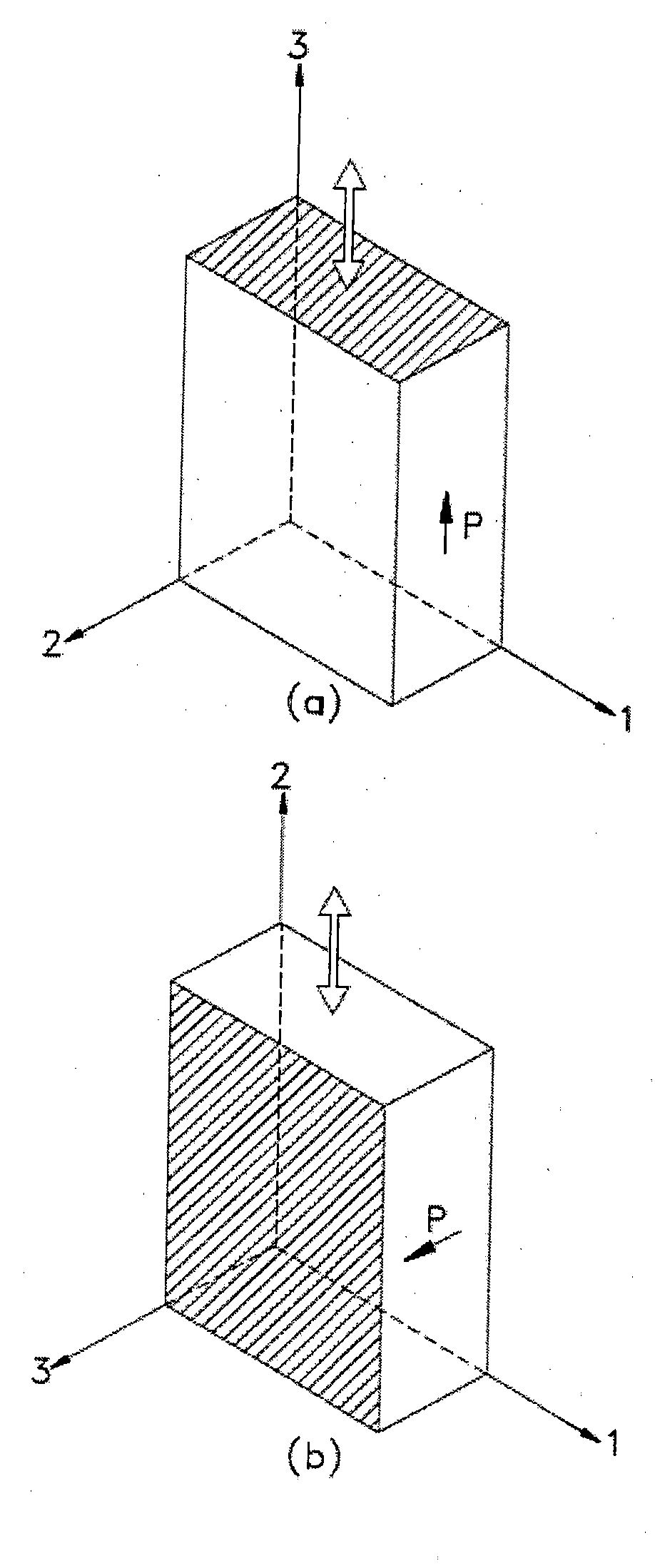

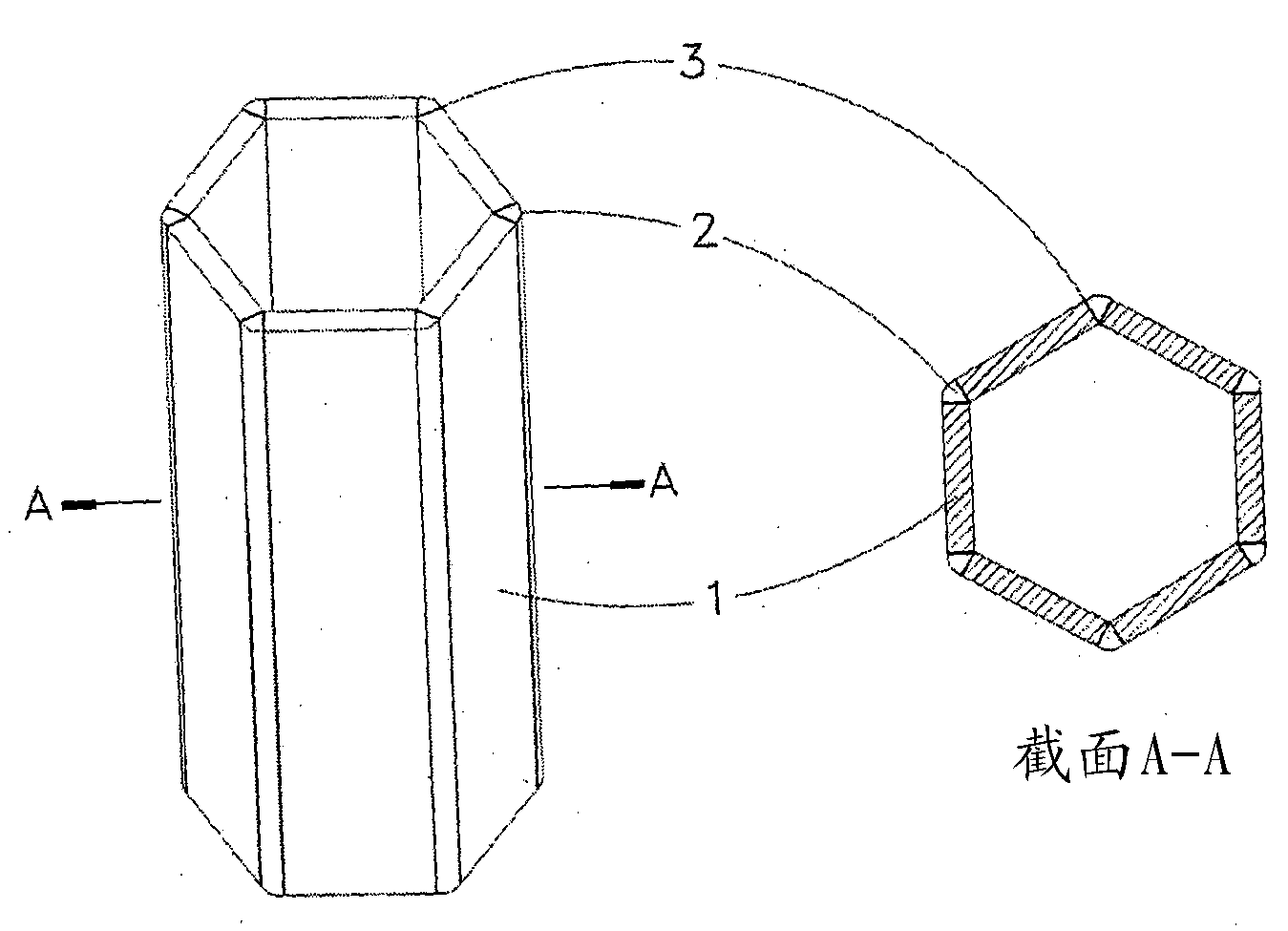

[0029] figure 1 A preferred embodiment of the invention is shown. Shown here is a multi-pile actuator with a central bore consisting of multiple longitudinal (d 33 ) or horizontal (d 31 or d 32 ) modal piezoelectric single crystal active elements, which are bonded together by epoxy resin by means of shaped edge reinforcements and top and bottom gasket reinforcements. Leads connected to the electrode faces (not shown in this and other figures) of the single crystal active element are provided for actuation purposes. figure 1 A multi-stake actuator is shown, where the stakes are the same piezoelectric single crystal active element with a suitable composition and cutting disc (1). The monocrystalline elements are bonded by epoxy to the desired configuration by means of shaped edge stiffeners (2) and bonded at both ends to shaped gasket stiffeners (4). Leads are bonded to the electrode faces of the crystal to complete the device (not shown in this and other figures). The bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com