Manufacturing method and manufacturing equipment of color steel tile

A manufacturing method, color steel tile technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

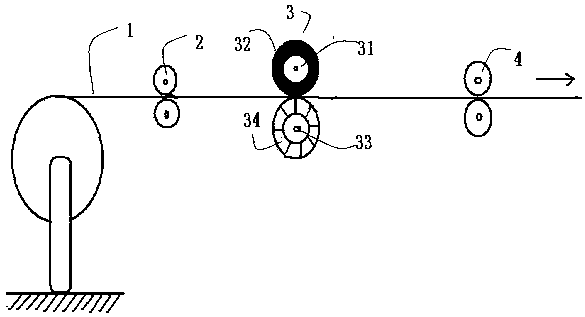

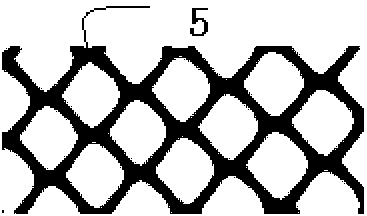

[0013] as attached figure 1 As shown, the molding equipment of the present embodiment includes a feed roller group 2, a forming roller group 3, and a discharge roller group 4; A layer of elastic rubber layer 32 is wrapped, and the upper roller 31 is in contact with the front of the colored coated steel sheet; the surface of the roller shaft of the lower roller 33 has a layer of bosses 34, and the shape of the bosses 34 is consistent with the shape to be pressed on the color steel tile. Correspondingly, the boss 34 of lower roller 33 is in contact with the back side of the colored coated thin steel plate; figure 2 As shown, the specific shape of the boss 34 in this embodiment is a grid shape, and the pressed color steel tile has a raised grid portion 5, and the color steel tile has a balanced anti-deformation strength in both length and width directions.

Embodiment 2

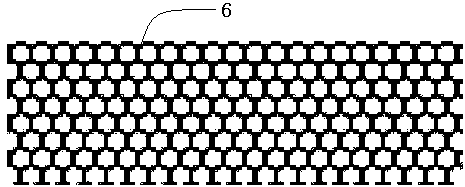

[0015] as attached figure 1 As shown, the molding equipment of the present embodiment includes a feed roller group 2, a forming roller group 3, and a discharge roller group 4; A layer of elastic rubber layer 32 is wrapped, and the upper roller 31 is in contact with the front of the colored coated steel sheet; the surface of the roller shaft of the lower roller 33 has a layer of bosses 34, and the shape of the bosses 34 is consistent with the shape to be pressed on the color steel tile. Correspondingly, the boss 34 of lower roller 33 is in contact with the back side of the colored coated thin steel plate; image 3 As shown, the specific shape of the boss 34 in this embodiment is a hexagonal grid, and the pressed color steel tile has a raised hexagonal grid 6, and the color steel tile has a balanced resistance in the length and width directions. deformation strength.

Embodiment 3

[0017] A manufacturing equipment for color steel tiles, comprising a feed roller set (2), a forming roll set (3), and a discharge roll set (4); it is characterized in that the forming roll set (3) consists of an upper roll ( 31) and the lower roller (33), the surface of the roller shaft of the upper roller (31) is covered with a layer of elastic rubber layer (32), the upper roller (31) is in contact with the front of the colored coated steel sheet; the lower roller (33) There is a layer of boss (34) on the surface of the roller shaft. The shape of the boss (34) corresponds to the shape to be pressed on the color steel tile. The boss (34) of the lower roller (33) and the back of the color-coated thin steel plate contact; the relative distance between the upper roll (31) and the lower roll (33) is adjusted by a mechanical or hydraulic system, which is used to adjust the degree of cold rolling deformation of the steel plate; when the steel plate (1) is continuously fed into the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com