A kind of ultra-thin glass bracket

A technology of ultra-thin glass and brackets, which is applied in the direction of rigid containers, fragile goods packaging, containers, etc., can solve the problems that the transportation and loading and unloading are not easy to ensure the quality of ultra-thin glass products, and achieve weight reduction, convenient operation and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

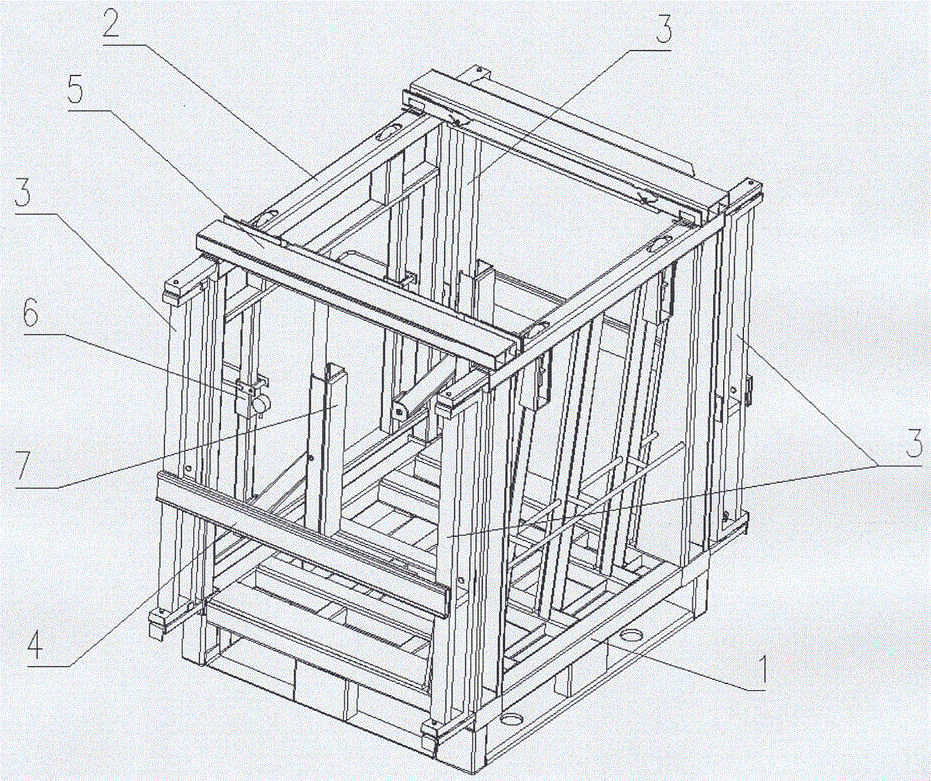

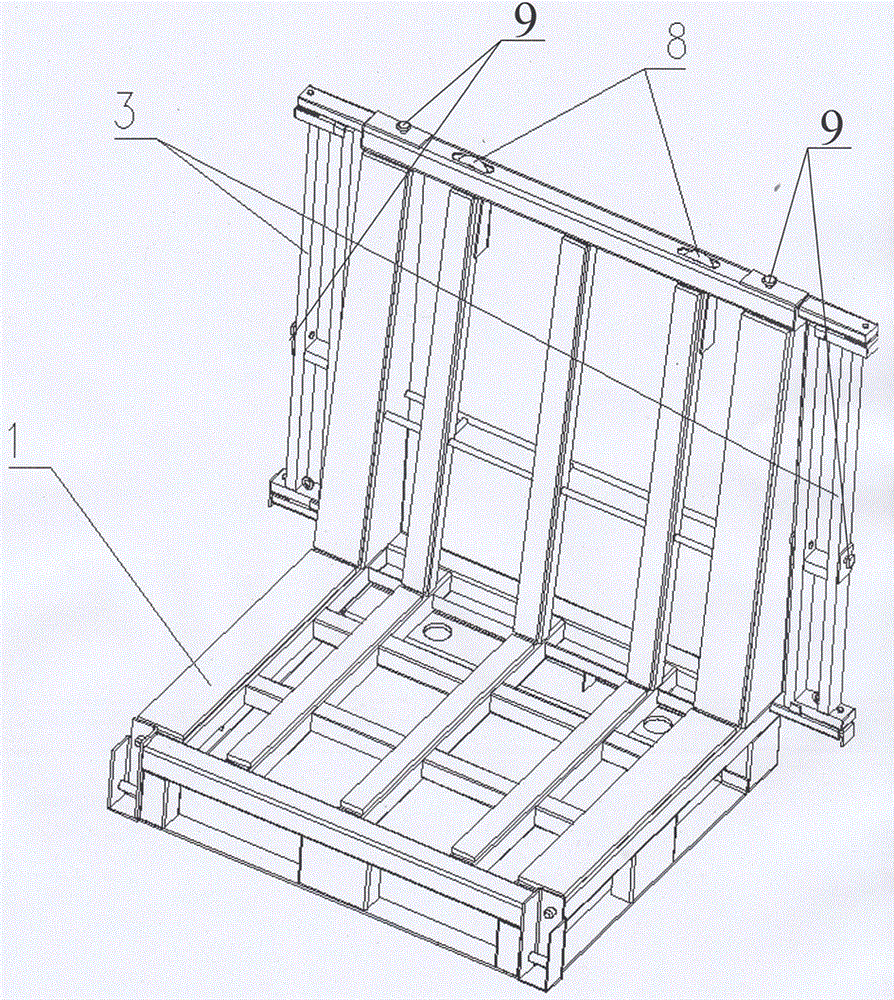

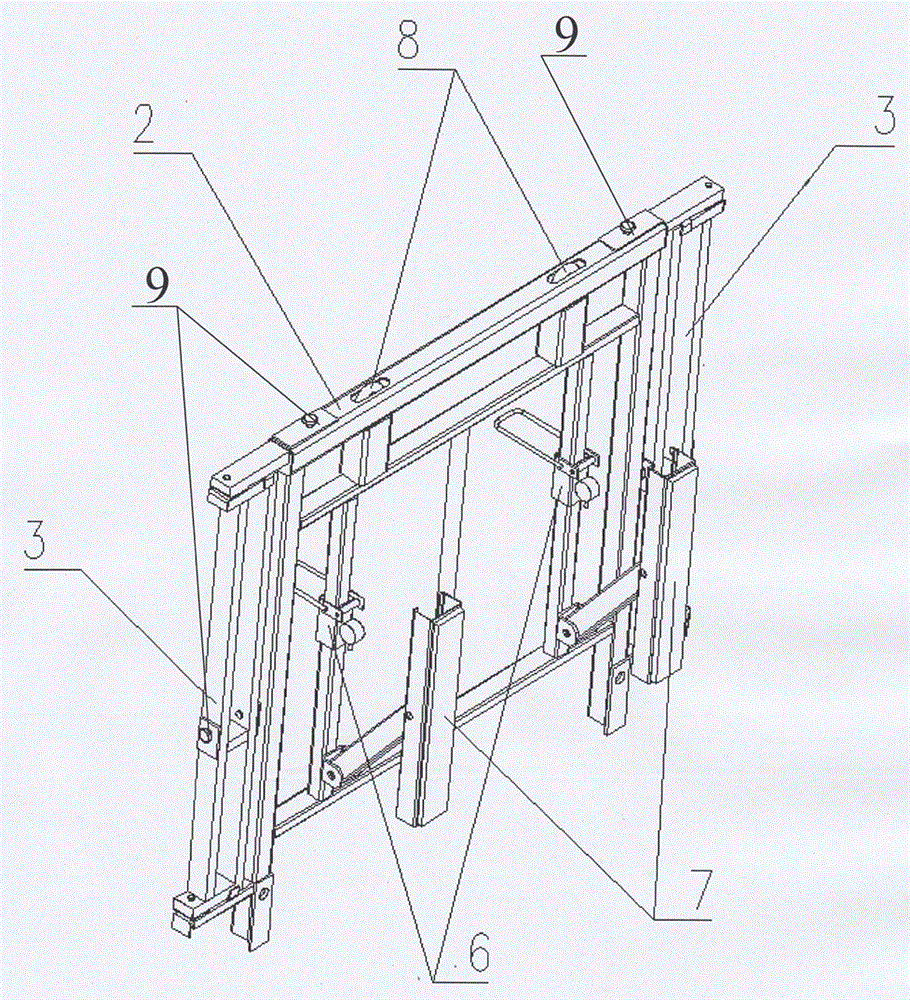

[0018] Such as figure 1 shown and figure 2 As shown, an ultra-thin glass bracket is used for stacking ultra-thin glass of 0.33 mm to 2 mm, including a base 1, one side of the base 1 is fixedly connected with a backrest, and the other side is provided with a detachable movable frame 2. The backrest and movable frame 2 are of the same height, each of which is provided with a pair of hidden hooks 8 and hidden buckles 9 symmetrically distributed about the vertical central axis, and also includes two top positioning rods 5 and two lower positioning rods 4. The top positioning rod 5 is installed between the backrest and the movable frame through the concealed buckle 9 to fix the backrest and the movable frame. Both sides of the backrest and the movable frame are provided with a rotatable frame 3, and the rotatable frame 3 The inner side is installed to the backrest and the side of the movable frame through the rotating shaft, and the lower part of the outer side is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com