Reinforcement cage lifting part

A technology of reinforcement cages and hangers, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems affecting the lifting safety of reinforcement cages, the welding quality cannot be guaranteed, the overhead holes are prone to cracks, etc., and achieves simple structure and low cost. , the effect of not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

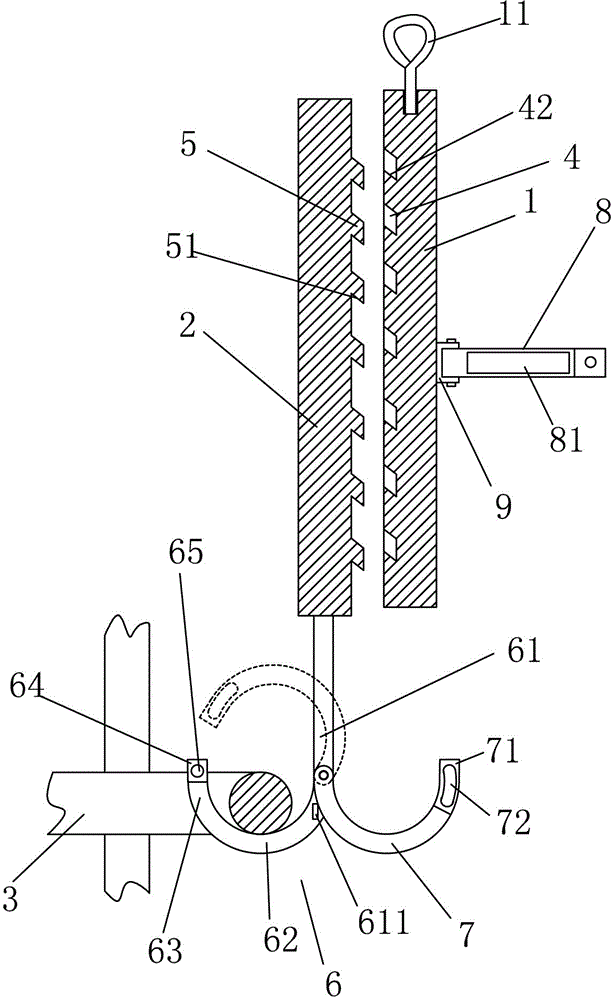

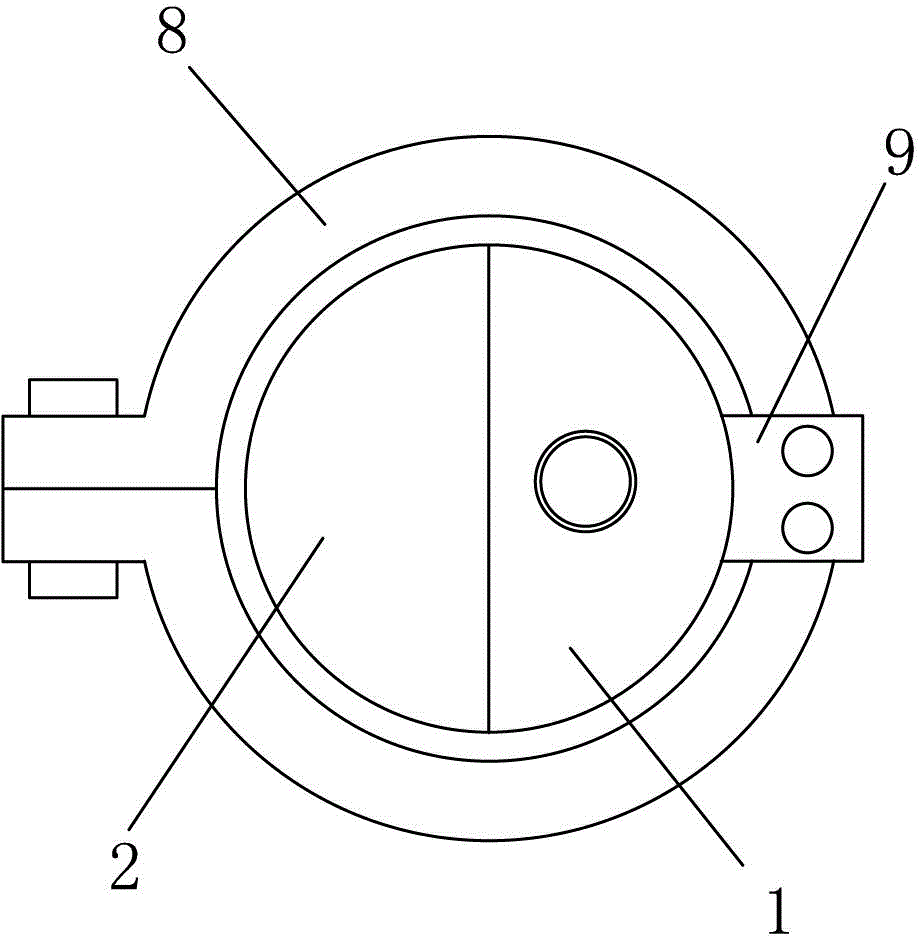

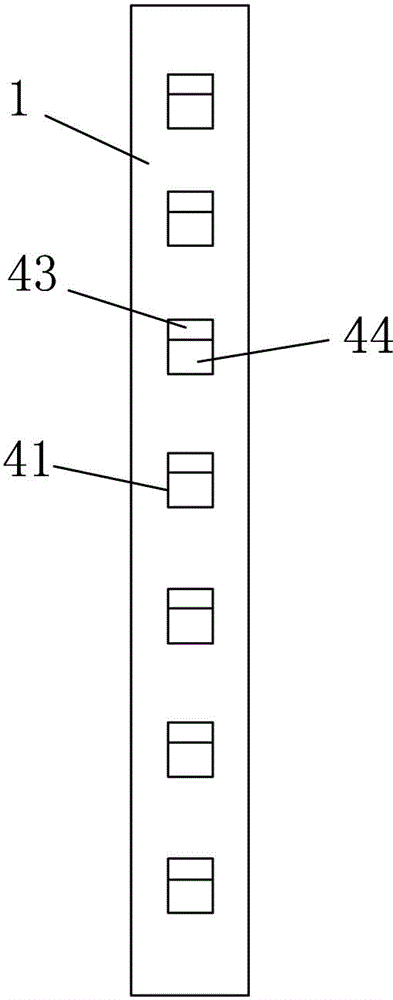

[0034] A reinforcement cage hanger, comprising a lifting rod 1 provided with a ring 11 at the top and a connecting rod 2 provided with a hook 6 for hooking a stirrup 3 on the reinforcement cage, the lifting rod and the connecting rod 2 being fitted with each other The boom is a semi-cylindrical rod, and the rod wall of the lifting rod and the connecting rod includes an arc surface and a plane. The center of the plane of the lifting rod 1 is evenly distributed from top to bottom with a number of inclined buckle grooves 4 arranged obliquely downward from the outside to the inside. The center of the plane of the connecting rod 2 is evenly distributed from top to bottom with an inclined insertion projection 5 that protrudes outwards and is arranged obliquely downward to insert into the inclined buckle groove 4. The inclined buckle groove includes a groove bottom wall 44, a groove upper wall 43, The slot lower wall 42 and the slot side wall 41 for restricting the movement of the inc...

Embodiment 2

[0040] The difference from the above embodiment is that the groove width of the inclined buckle groove is 3 / 4 of the plane width of the lifting rod.

Embodiment 3

[0042] The difference from the above embodiment is that the groove width of the inclined buckle groove is 1 / 2 of the plane width of the lifting rod.

[0043] When in use, match the connecting rod and the lifting rod according to the required length. After the two rods are plugged in, fix the two rods with hoops, screw the ring to the lifting rod, and hook the hook to the stirrup, as shown in the figure Flip the locking hook counterclockwise and fix the locking hook and the hook with the pin.

[0044] The invention has the advantages of simple structure, low cost, convenient assembly and disassembly, reusability and long service life. When the invention is used, the reinforcement cage shakes less, the hoisting is stable, and the operation is safe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com