A kind of ionothermal synthesis method of microspherical porous basic magnesium borate and magnesium borate nano superstructure

A synthesis method and technology of magnesium borate, applied in borate, nanotechnology, nanotechnology and other directions, to achieve the effects of low synthesis temperature, suitable for industrial promotion and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

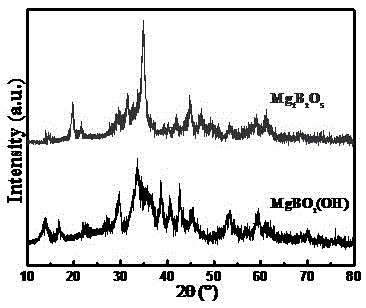

[0031] Use KOH as a pH regulator to adjust the pH of N,N-dimethylformamide nitrate ionic liquid to 8.0-9.0, and 4.066gMgCl 2 ?6H 2 O is added to the ionic liquid with a pH of 8.0-9.0 under stirring, and then press Mg 2+ :H 3 BO 3 Add H to the mixture at a molar ratio of 1:2 3 BO 3 , after stirring for 10 minutes, transfer it to a polytetrafluoroethylene-lined reaction kettle, raise the temperature to 160oC for 12 hours, cool down naturally after the reaction, wash, filter and dry the product to obtain porous basic magnesium borate superstructure nanomaterials, and the filtrate Recover as a solvent for recycling; place the obtained product in an air roaster, heat up to 650oC at a heating rate of 2oC / min for 6h, and the obtained product is washed, filtered, and dried to become a porous magnesium borate superstructure nanomaterial.

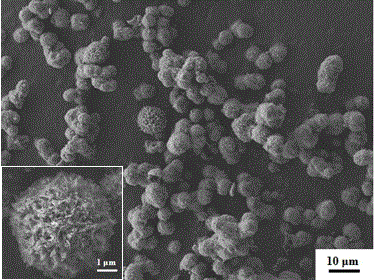

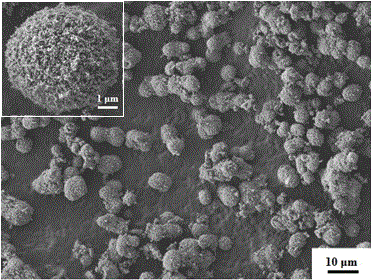

[0032] 82% of the size distribution of the basic magnesium borate nano-superstructure prepared in this example is 4.5-5.5 μm, and 80% of the si...

Embodiment 2

[0034] Use NaOH as the pH regulator to adjust the pH of the N,N-dimethylformamide nitrate ionic liquid to 8.0-8.5, and then add 4.066gMgCl 2 ?6H 2 O is added to the ionic liquid with a pH of 8.0-8.5 under stirring, and then press Mg 2+ :H 3 BO 3 Add H to the mixture at a molar ratio of 2:3 3 BO 3 , stirred for 10 minutes, added a small amount of NaOH to ensure that its pH was maintained at 8.0-8.5, then transferred it to a polytetrafluoroethylene-lined reactor, raised the temperature to 150oC and reacted for 12 hours, and cooled down naturally after the reaction, and the product was washed, Filtrate and dry to obtain porous basic magnesium borate superstructure nanomaterials, and the filtrate is recovered as a solvent for recycling; the resulting product is placed in an air roaster, and the temperature is raised to 600oC at a heating rate of 5oC / min for 12h, and the obtained product is washed, Filtration and drying are porous magnesium borate superstructure nanomaterials....

Embodiment 3

[0037] Use NaOH as a pH regulator to adjust the pH of the mixture of N,N-dimethylformamide hydrochloride ionic liquid and water at a volume ratio of 6:1 to 7.5-8.5, and then add 5.128gMg(NO 3 ) 2 ?6H 2 O is added to the ionic liquid with a pH of 8.0-8.5 under stirring, and then press Mg 2+ :Na 2 B 4 o 7 10H 2 O molar ratio is 2:1, adds Na in the mixed solution 2 B 4 o 7 10H 2 O, stir for 10 minutes, add a small amount of KOH to ensure that the pH is maintained at 8.0-8.5, then transfer it to a polytetrafluoroethylene-lined reactor, heat up to 140oC for 12 hours, cool down naturally after the reaction, and wash the product , filtered, and dried to obtain porous basic magnesium borate superstructure nanomaterials, and the filtrate is recycled as a solvent for recycling; the resulting product is placed in an air roaster, and the temperature is raised to 700oC at a heating rate of 10oC / min for 2 hours, and the obtained product is washed , filtering, and drying are porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com