Floor slab for kitchen/bathroom

A floor, kitchen and bathroom technology, applied to floors, building components, buildings, etc., can solve the problems of high cost of all-steel structure floors, heavy concrete floors, inconvenient and rapid construction, etc., to achieve convenient and fast connection, good earthquake resistance, connection and assembly quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

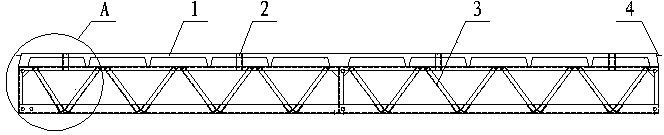

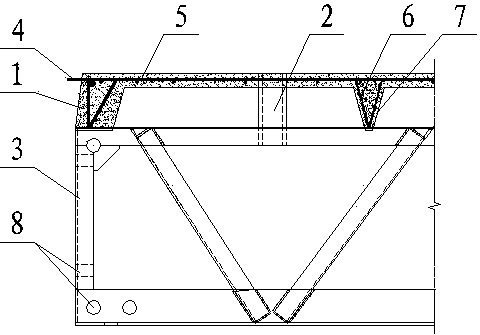

[0020] Such as figure 1 , figure 2 As shown, a floor slab for kitchen and bathroom includes a steel frame 3 and a kitchen and bathroom concrete floor 1 on the steel frame 3 . The kitchen and bathroom concrete floor 1 is composed of concrete slabs and vertically and horizontally intersecting flutes 7 . The steel frame 3 is welded by long truss beams and short transverse truss beams, the long truss beams and short truss beams are provided with connecting holes 8 of generalized modulus for connecting with columns or beams, and the concrete slab The surface is an inclined plane, which automatically forms a slope. The concrete slab is provided with a steel mesh 5, and the corrugated 7 is provided with a steel truss 6. The steel mesh 5 and the steel truss 6 are connected to each other. The truss 6 is connected with the steel frame 3 .

[0021] The reinforcement mesh is composed of vertically and horizontally intersecting steel wires, and the reinforcement truss 6 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com