Assembling and shaping fixture for vehicle-mounted battery pack system module and assembling and shaping method thereof

A technology for system modules and battery packs, applied in battery pack components, assembled battery machines, secondary battery manufacturing, etc., can solve problems such as the inability to achieve module reshaping tasks, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

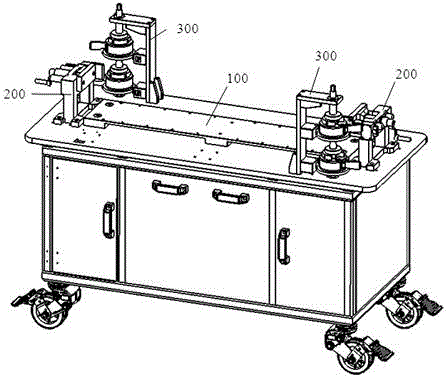

[0040] Such as figure 1 As shown, the present invention discloses a vehicle-mounted battery pack system module assembly shaping tool, which includes: a bearing component 100 , a shaping component 200 and a fixing component 300 .

[0041] The carrying assembly 100 is fixed on any tooling platform, and the carrying assembly 100 has a rectangular shape as a whole. Two shaping components 200 are respectively disposed at two ends of the carrying component 100 . The two fixing components 300 are correspondingly disposed on the sides of the two shaping components 200 .

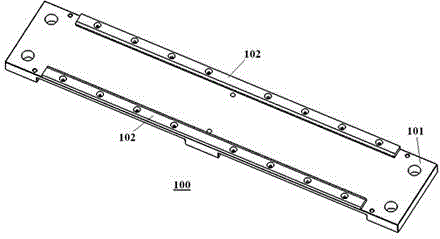

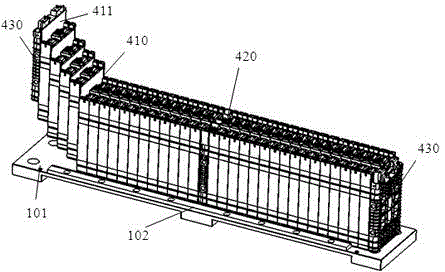

[0042] Such as figure 2 As shown, the carrier assembly 100 includes a module assembly tray 101 fixed on any tooling platform, and a pair of limit stops 102 arranged in parallel on the module assembly tray 101 . The module assembly tray 101 is a rectangular steel plate with through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com