Frequency calibration method, device and system for oven controlled crystal oscillator

A constant temperature crystal oscillator and crystal oscillator technology, applied in the direction of power oscillators, electrical components, etc., can solve the problems that cannot meet the high performance indicators of constant temperature crystal oscillators, are not accurate enough, and cannot continuously guarantee stable output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

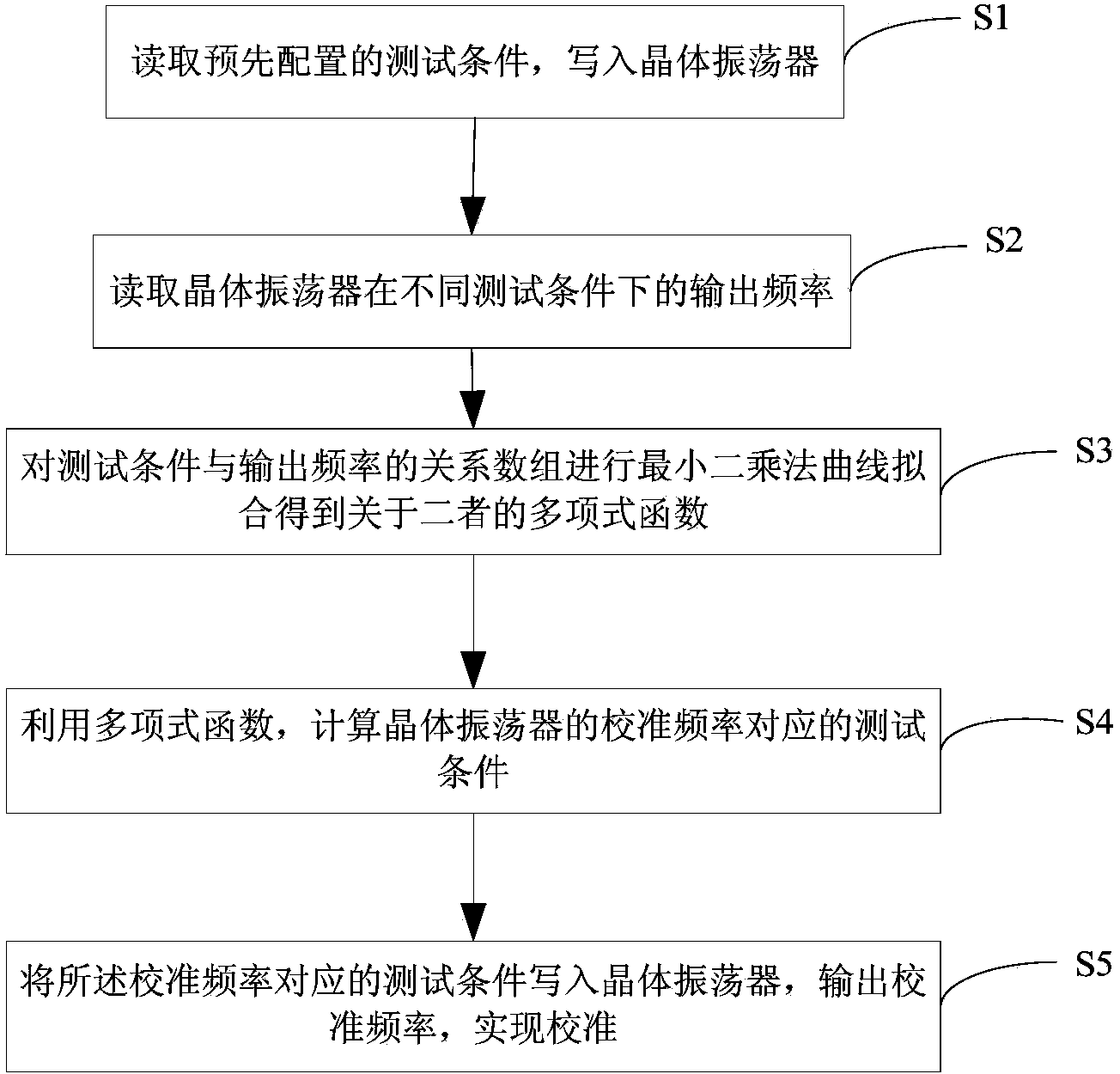

[0049] figure 1 It is a flow chart of a frequency calibration method for an ovenized crystal oscillator provided in Embodiment 1 of the present invention. Such as figure 1 As shown, a kind of constant temperature crystal oscillator frequency calibration method described in the present invention comprises:

[0050] S1. Read the pre-configured test conditions and write them into the crystal oscillator;

[0051] S2, read the output frequency of the crystal oscillator under different test conditions;

[0052] S3, performing least squares curve fitting on the relationship array of test conditions and output frequency to obtain a polynomial function about test conditions and output frequency;

[0053] S4. Using a polynomial function, calculate the test condition corresponding to the calibration frequency of the crystal oscillator;

[0054] S5. Write the test condition corresponding to the calibration frequency into the crystal oscillator, output the calibration frequency, and real...

Embodiment 2

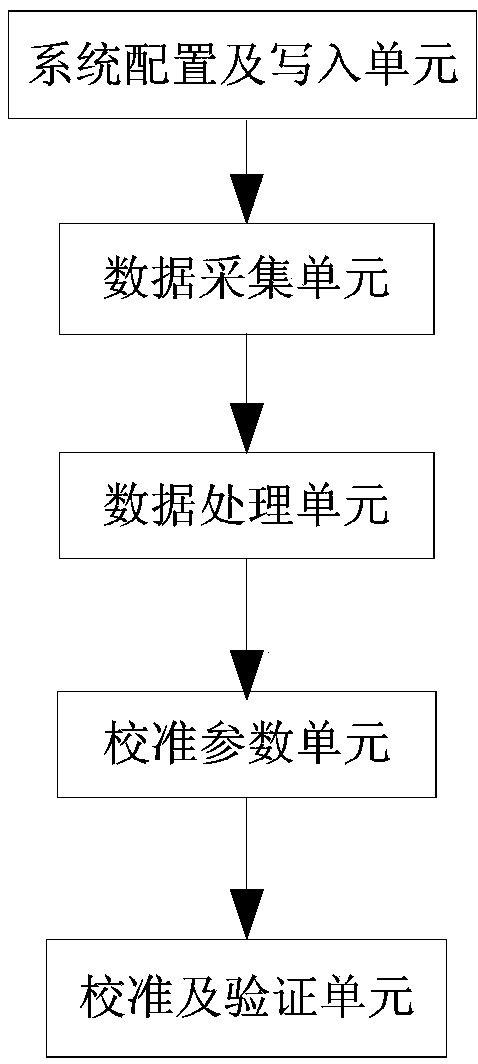

[0068] Embodiment 2: The following is the device embodiment of the embodiment of the present invention. The method embodiment, device embodiment, and system embodiment of the present invention belong to the same concept. Details that are not described in detail in the device embodiment and system embodiment can be Refer to the above method embodiment. figure 2 It is a schematic structural diagram of a constant temperature crystal oscillator frequency calibration device provided in Embodiment 2 of the present invention. Such as figure 2 As shown, a constant temperature crystal oscillator frequency calibration device according to the present invention includes:

[0069] The system configuration and writing unit is used to read the pre-configured test conditions and write to the crystal oscillator;

[0070] The data acquisition unit is used to read the output frequency of the crystal oscillator under different test conditions;

[0071] The data processing unit is used to per...

Embodiment 3

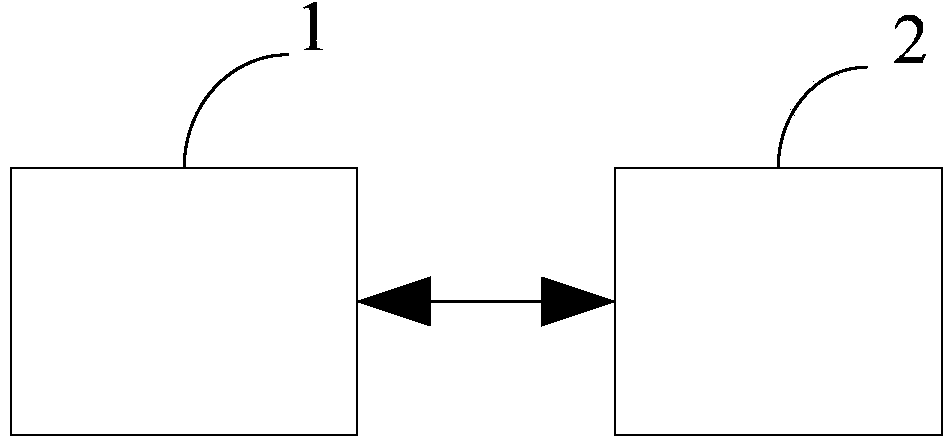

[0084] Embodiment 3: The following is the system embodiment of the embodiment of the present invention. The method embodiment, device embodiment, and system embodiment of the present invention belong to the same concept. Details that are not described in detail in the device embodiment and system embodiment can be Refer to the above method embodiment. image 3 It is a structural schematic diagram of a constant temperature crystal oscillator frequency calibration system provided by Embodiment 3 of the present invention. Such as image 3 As shown, a constant temperature crystal oscillator frequency calibration system according to the present invention includes: a test hardware device 2, and a PC 1 connected to the test hardware device 2 through a communication interface;

[0085]The PC 1 is used to read preset test conditions, control the test hardware device 2 to write the test conditions into the crystal oscillator, read the output frequency of the crystal oscillator returned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com