Novel large-channel electrophoresis microchip

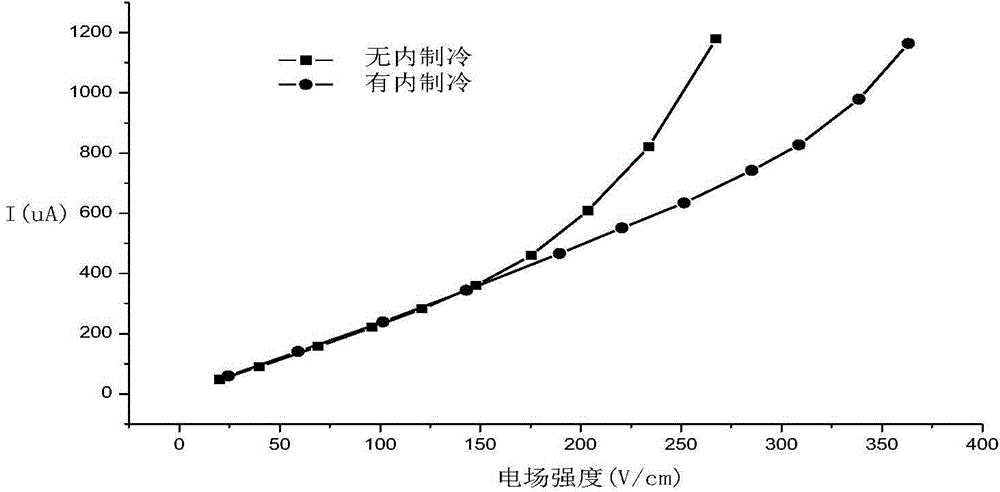

A large channel and microchip technology, which is applied in the direction of material analysis, measurement device, and instrument by electromagnetic means, can solve the problem of low sample load of capillary microfluidic chip, and achieve the effect of solving the excessive Joule heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

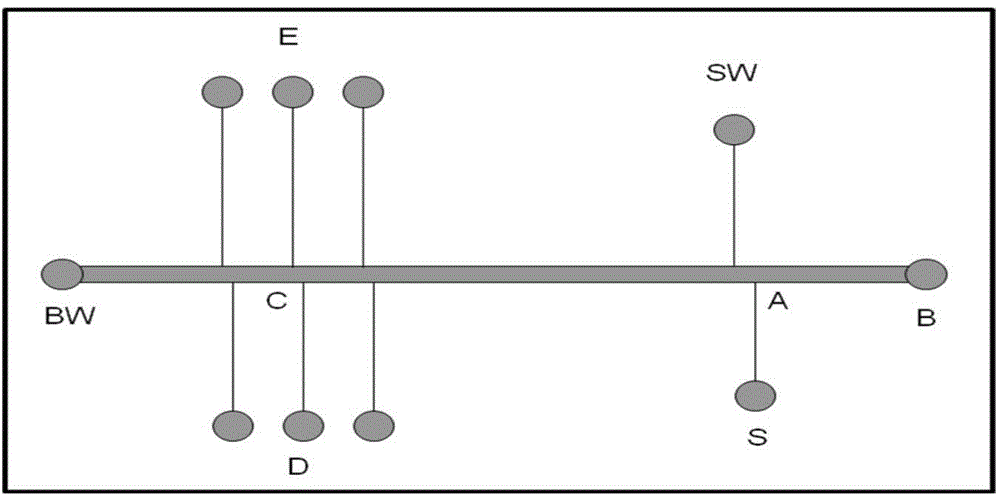

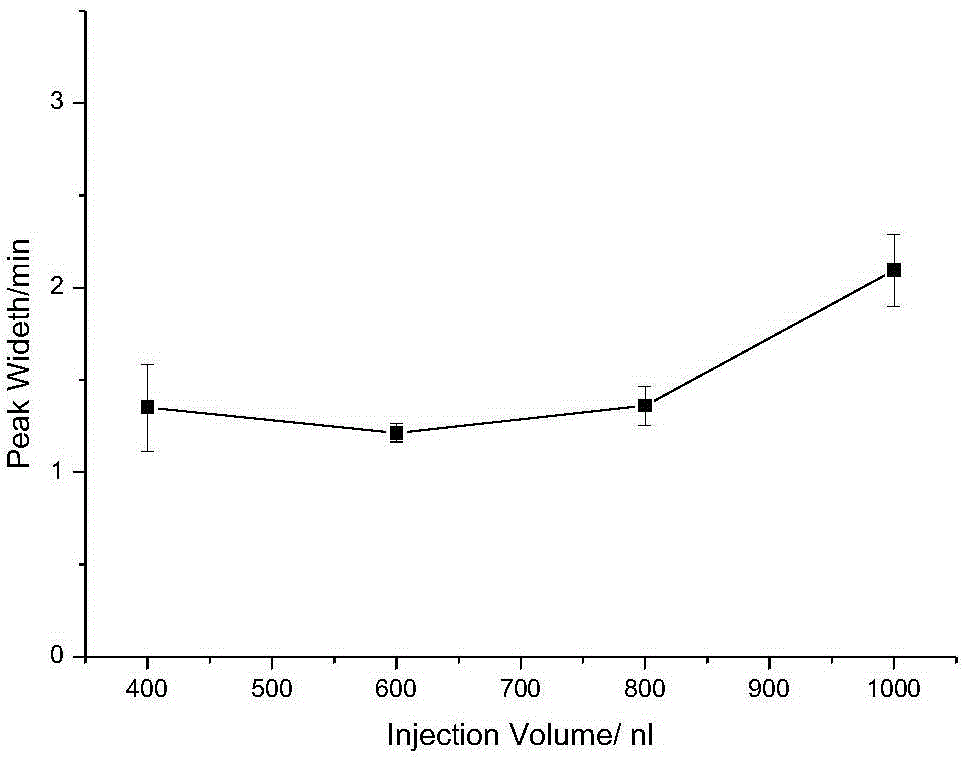

[0040] designed as figure 1 The chip shown, where the distance between B and BW is 10.5cm, and the channel diameter is 1mm; A is the injection site; the distance between S and SW is 1.1cm; the stagger distance between A, S and A, SW is 1mm; A and C The distance between them is 6.5cm; the chips are made according to the steps in the technical scheme. Use the "double T-type" channel electrosampling method to analyze organic acid samples:

[0041] Experimental conditions: buffer: 10mM acetic acid-sodium acetate buffer (containing 0.6% HEC) at pH4.0; sample: 1mg / mL benzoic acid, 2mg / mL p-toluenesulfonic acid mixture; effective length / total length=6.5cm / 10.5cm; detection wavelength: 259nm; injection voltage 300V; injection current 300μA; injection time 60s; negative electrode injection; separation voltage 1000V; current 220-240μA; / min. The result is as Figure 6 , where 1 is p-toluenesulfonic acid; 2 is benzoic acid.

Embodiment 2

[0043] designed as figure 1 The chip shown, where the distance between B and BW is 10.5cm, and the channel diameter is 1mm; A is the injection site; the distance between S and SW is 1.1cm; the stagger distance between A, S and A, SW is 1mm; A and C The distance between C and D is 6.5cm; the channel between C and D adopts the method of inserting a capillary, and the effective length of the channel / total length=13.5cm / 27.5cm is obtained; the chip is manufactured according to the steps in the technical solution (c). Using the "double T-type" channel electrosampling method and the three-electrode transfer mode to analyze organic acid samples:

[0044] Experimental conditions: one-dimensional buffer: 10mM acetic acid-sodium acetate buffer at pH4.0; two-dimensional buffer: 40mM acetic acid-sodium acetate buffer at pH4.5; samples: 1mg / mL benzoic acid, 2mg / mL Mixed solution of toluenesulfonic acid; negative electrode sample injection; 300V, 90s; transfer voltage: point B is -1000V, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com