Slant film tearing platform with anti-falling mechanism on full-automatic backlight assembly machine

An assembly machine and fully automatic technology, which is applied in the direction of layered products, lamination auxiliary operations, lamination, etc., to achieve the effects of cost reduction, smooth operation, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The mechanism of the present invention mainly involves the removal of the coating film on the surface of the liquid crystal screen, so that the subsequent assembly of the backlight sheet can be realized in the automatic backlight assembly machine. The conveying manipulator used for holding and conveying the liquid crystal screen in the automatic backlight assembly machine of the prior art is already a molding technology, and the present invention can be directly implemented in the manner of the prior art.

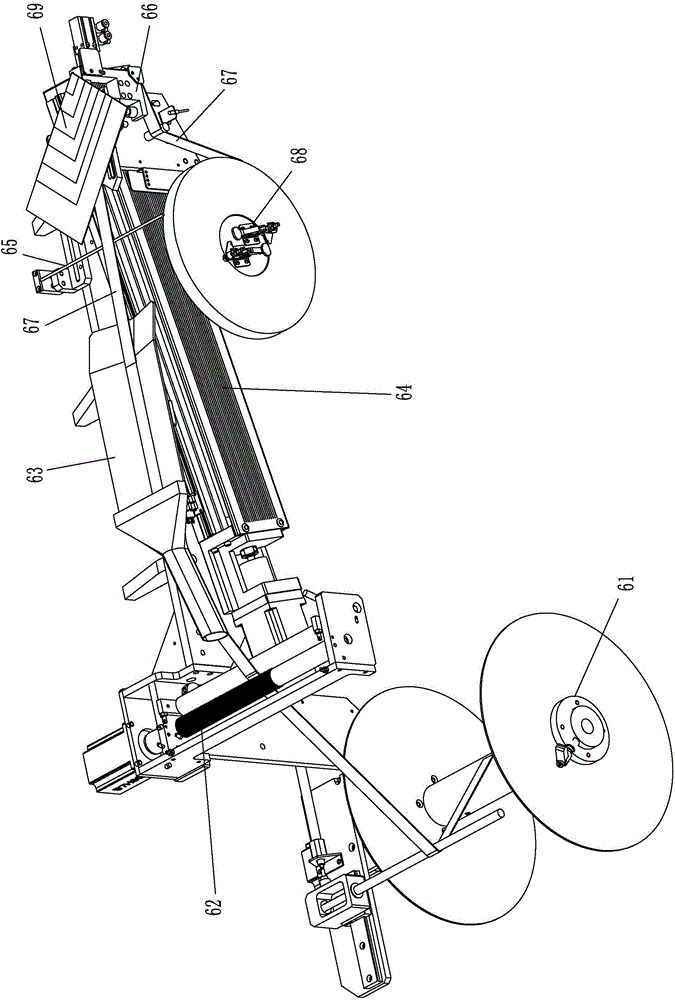

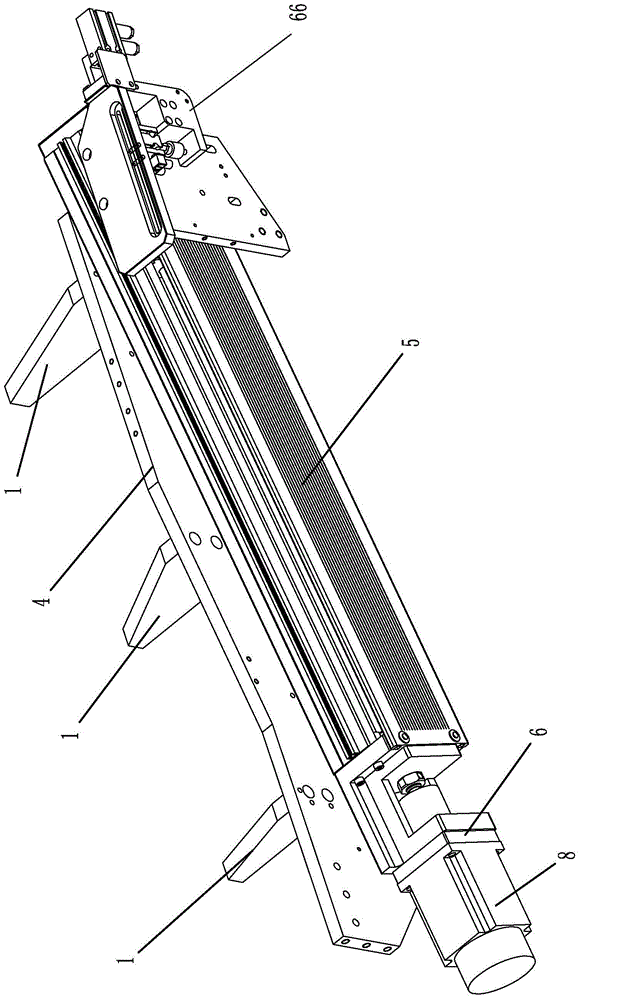

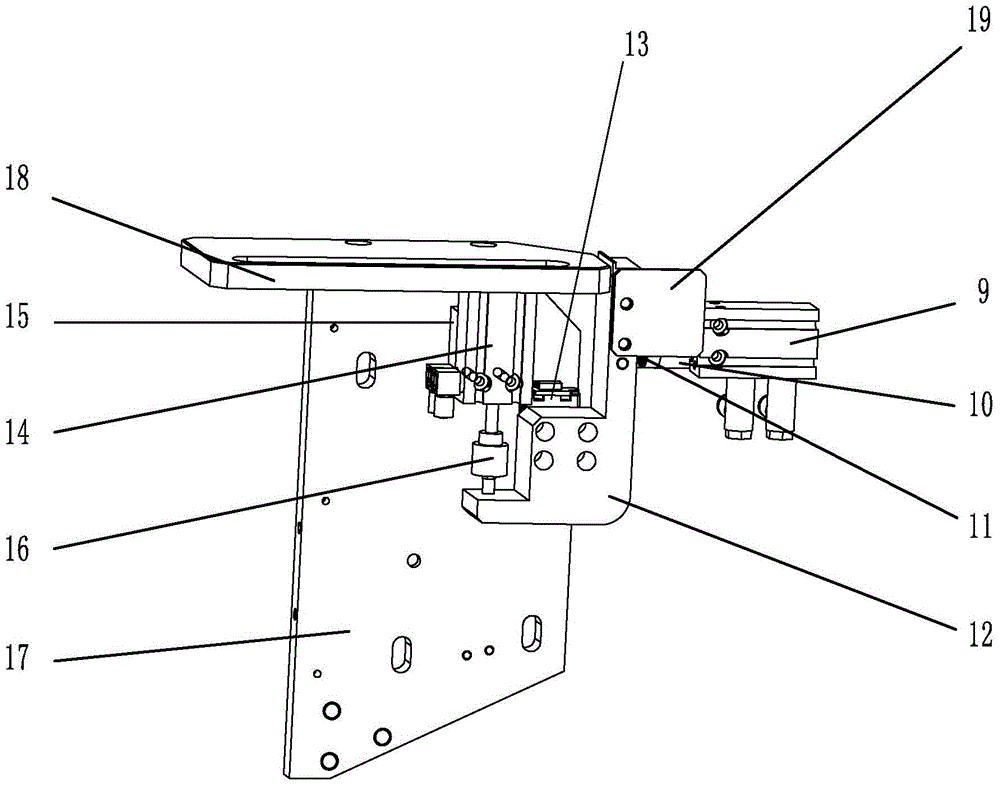

[0020] And the automatic backlight assembly machine of the present invention oblique tear film platform mechanism, as figure 1 As shown, on the basis of the above-mentioned conveying manipulator, it also includes a support unit 66 that presses the adhesive surface of the adhesive tape 67 upward to the side of the liquid crystal screen 69 facing the film surface below, and drives the support unit 66 to press the film. An actuator 64 that moves and moves back on the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com