Engine supporting foot for flexible base

A flexible base and engine technology, applied in the direction of power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve problems such as damage and engine deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in conjunction with accompanying drawing and specific embodiment:

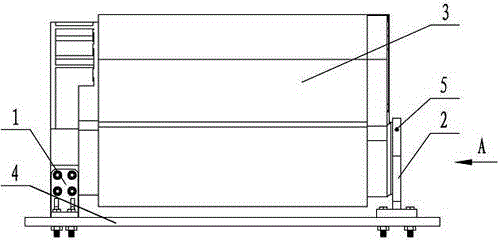

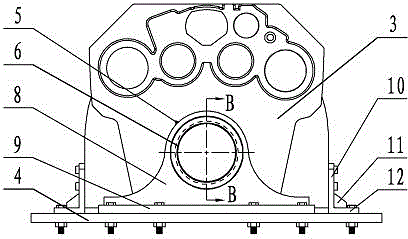

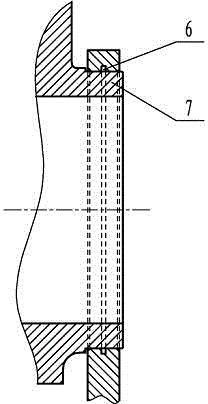

[0012] An engine foot for a flexible base, including: a rear foot and a front foot; there are two rear feet 1, which are arranged at the rear end (flywheel end) of the engine, and consist of a side plate 10, a bottom plate 12, ribs The plate 11 is welded; 4 bolt mounting holes are arranged on the side plate 10, and the rear end leg of the side plate 10 is connected with the engine 3 through 4 bolts; Bolts connect the rear end leg 1 with the flexible base 4 . The front-end support foot 2 is arranged at the front end of the engine (shock absorber end), and is welded by a vertical plate 8 and a horizontal plate 9; a shaft hole is arranged on the vertical plate 8, and the shaft hole is matched with the support shaft provided on the engine with clearance , the engine support shaft can rotate freely in the shaft hole, and there is an oil groove 6 for lubrication in the enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com