A base plate used for engineering machinery cab

A technology for engineering machinery and cabs, which is applied to the floor of construction machinery cabs, can solve the problems of insufficient bending resistance, torsion resistance, outstanding contribution of vibration and sound radiation, etc., to achieve reduced vibration and sound radiation, good application prospects, Good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

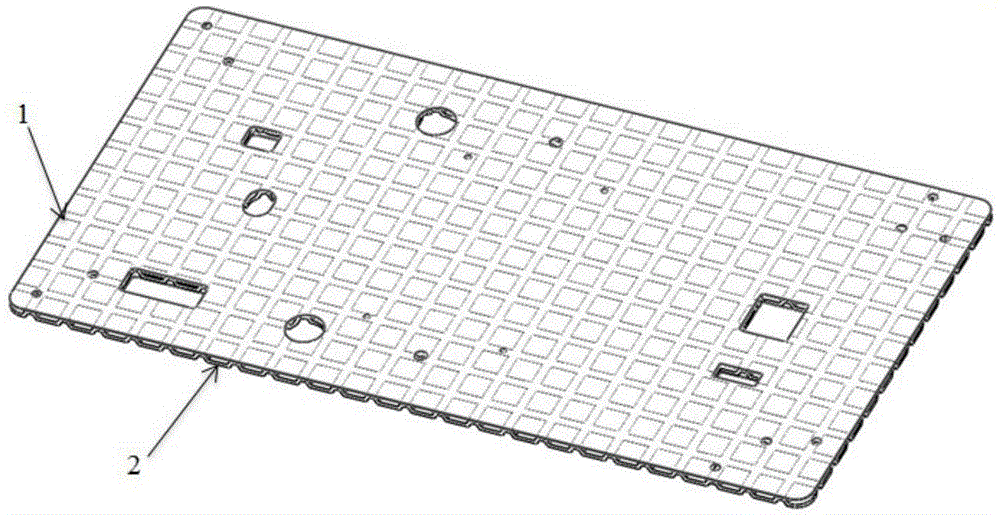

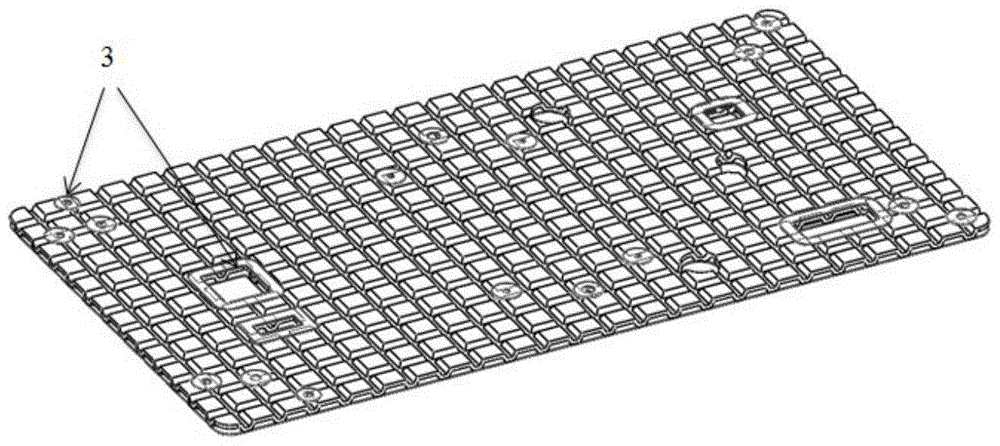

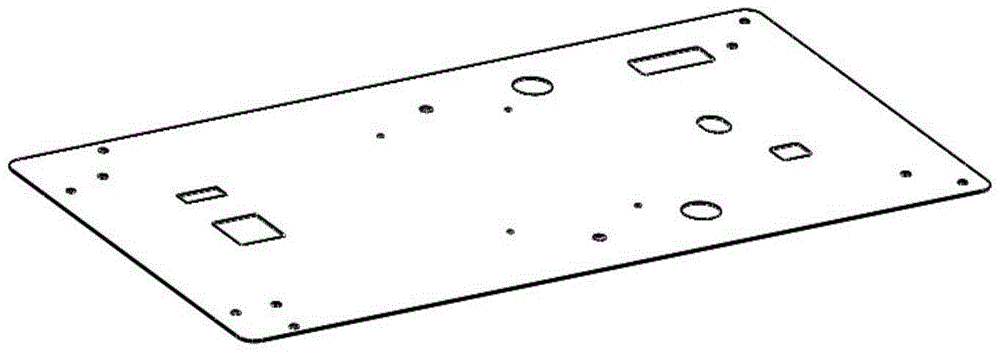

[0038] like Figure 1 to Figure 5 As shown, a bottom plate for construction machinery cab of the present invention includes an upper plate 1, a lower prestressed reinforcement plate 2 and a positioning plate 3 all made of steel plates. The upper plate 1 is welded on the top surface of the lower prestressed reinforced plate 2 , and the positioning plate 3 is welded on the bottom surface of the lower prestressed reinforced plate 2 . Through the stamping process, reinforcing ribs are formed on the surface of the lower prestressed reinforcing plate 2 , and structural prestress is formed inside the lower prestressed reinforcing plate 2 . The reinforcement ribs include transverse reinforcement ribs 4 and longitudinal reinforcement ribs 5 that criss-cross.

[0039] The bottom plate of the construction machinery cab with the above structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com