Multi-row and multi-shaft cemented soil mixing pile drilling machine

A technology of cement-soil mixing piles and mixing piles, applied in the direction of earth cube drilling, drill pipes, drill pipes, etc., can solve the problems of long time consumption and slow construction speed, reduce lap cold joints, improve construction quality, and reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

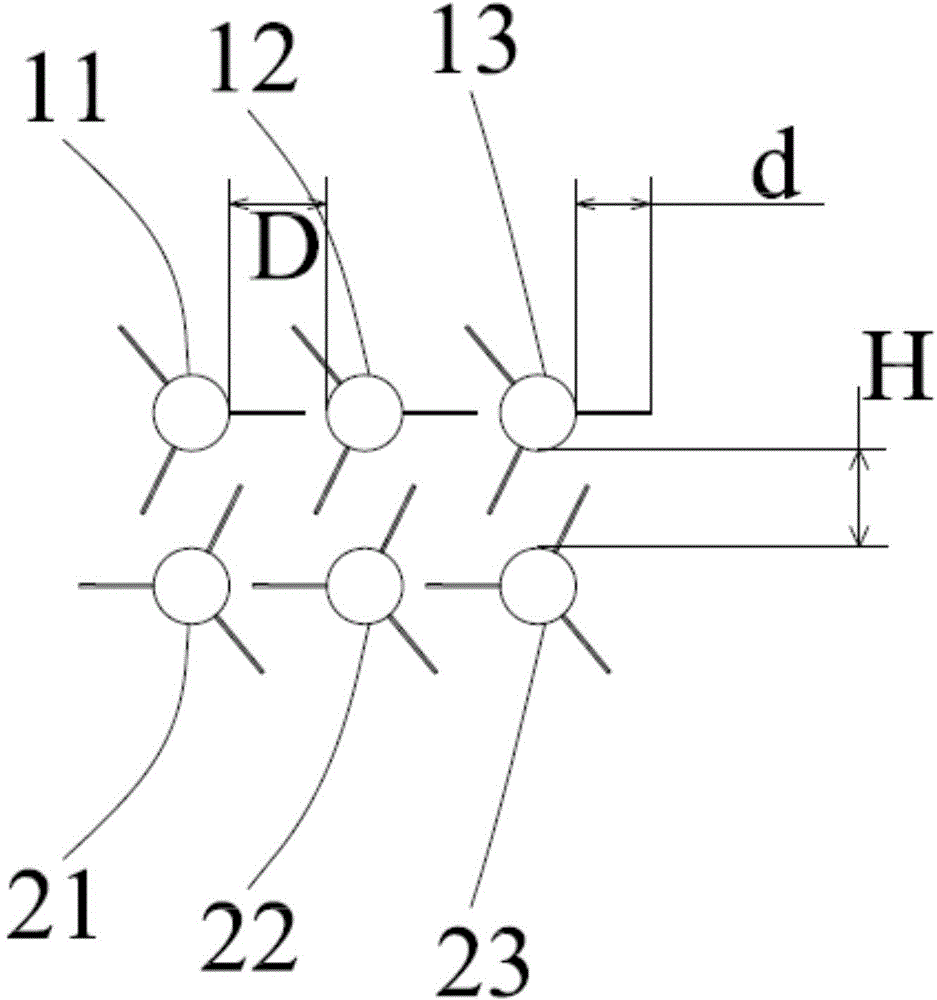

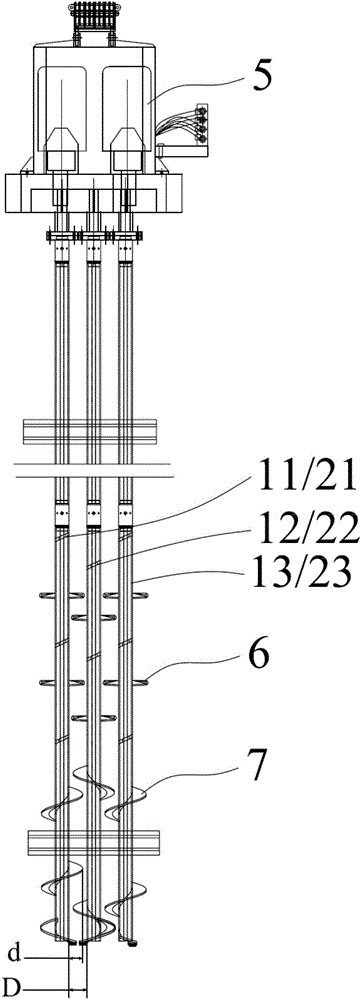

[0025] Example 1, see figure 1 and figure 2 , the present embodiment is 2 rows of double-row agitating pile machines with three shafts in each row. The three drill rods in each row and the mixing heads are arranged in a line by overlapping, and a power box 5 is arranged above the three drill rods in 2 rows. The power box A driving motor is arranged inside. The output shaft of the motor is connected with a reducer, and the reducer is connected with the drill pipe. In this way, the rotating speed of the drill rod can be controlled, and the required rotating speed requirement has been reached without damaging the motor.

[0026] The first row of drill rods from left to right is the first drill rod 11, the second drill rod 12, and the third drill rod 13, and the three drill rods are arranged in a row; the second row of drill rods is the first drill rod from left to right. One drill rod 21, the second drill rod 22, the third drill rod 23, three drill rods are arranged in a row....

Embodiment 2

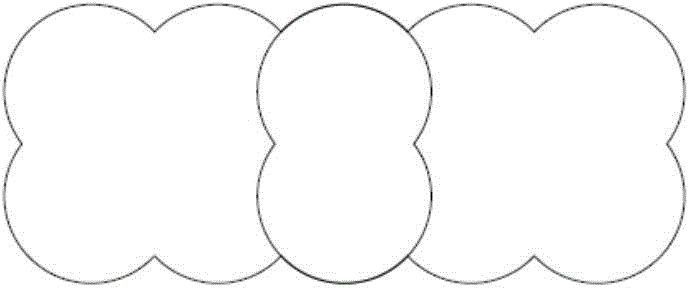

[0032] Example 2, see Figure 4 , increase the row spacing H between the two rows of drill pipes, d>H / 2, and 6 drill pipes rotate simultaneously to form 2 rows of cement-soil mixing piles that do not overlap each other. For pile plan, see Figure 5a , Figure 5b , Two rows of three mixing piles in each row can be piled at one time, and each row of mixing piles is overlapped or sleeved, but the rows are not overlapped with each other. All the other are with embodiment 1.

[0033] According to the actual situation, the present invention can be changed into a double-row four-axis mixing pile machine, a double-row five-axis mixing pile machine, etc.; the corresponding drill pipe drainage can also be changed, such as three-row, four-row, five-row drilling rigs, etc. . Multiple rows of cement-soil mixing piles are formed at the same time, which reduces the overlap cold joints.

[0034] The multi-row multi-axis cement-soil mixing pile drilling rig of the present invention can co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com