Submersible pump

A submersible pump and pump casing technology, applied in the field of liquid pumps, can solve problems such as insufficient efficiency research, and achieve the effects of enhanced water drawing efficiency, high working efficiency, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

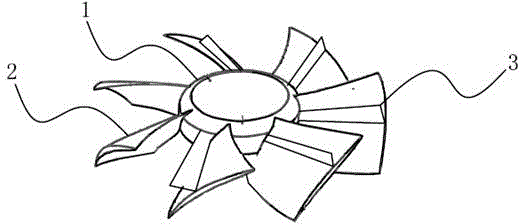

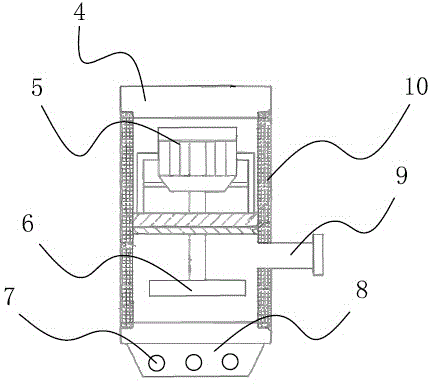

[0015] A kind of submersible pump of the present embodiment comprises a pump casing 4, a motor 5, an impeller 6, a water outlet 9 and a base 8, the outer wall of the base 8 is provided with a water inlet 7 and is fixed on the lower end of the pump casing 4, the impeller 6 and the motor 5 The shaft of the shaft is fixedly connected by a pin key, the impeller 6 is arranged near the base 8, and the water outlet 9 is arranged on the side wall of the pump casing 4. The impeller 6 includes a hub 1 and seven blades 2 arranged around the periphery of the hub. The blades 2 are detachably installed on the hub 1. The blades 2 are curved structures. Each blade 2 is provided with a convex surface 3, and the convex surface 2 is connected to the blade of the blade. The angle between the surfaces is 60 degrees, and one end of the convex surface 3 is close to the hub 1 and radiates outward along the extending direction of the blades 2 . A water seal is provided between the base 8 and the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com