Safety double-sealed ball valve

A double-sealing, ball valve technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of high-risk chemical product leakage, valve body burst, pressure can not be discharged, etc., to achieve compact and simple structure, reliable bilateral sealing, Simple opening and closing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

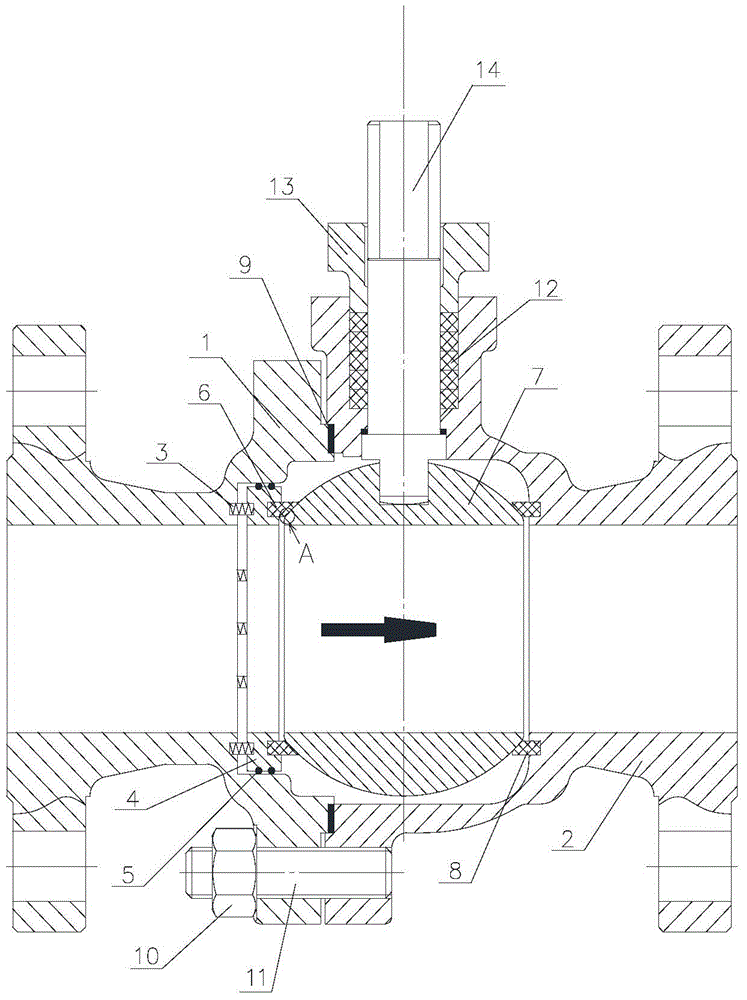

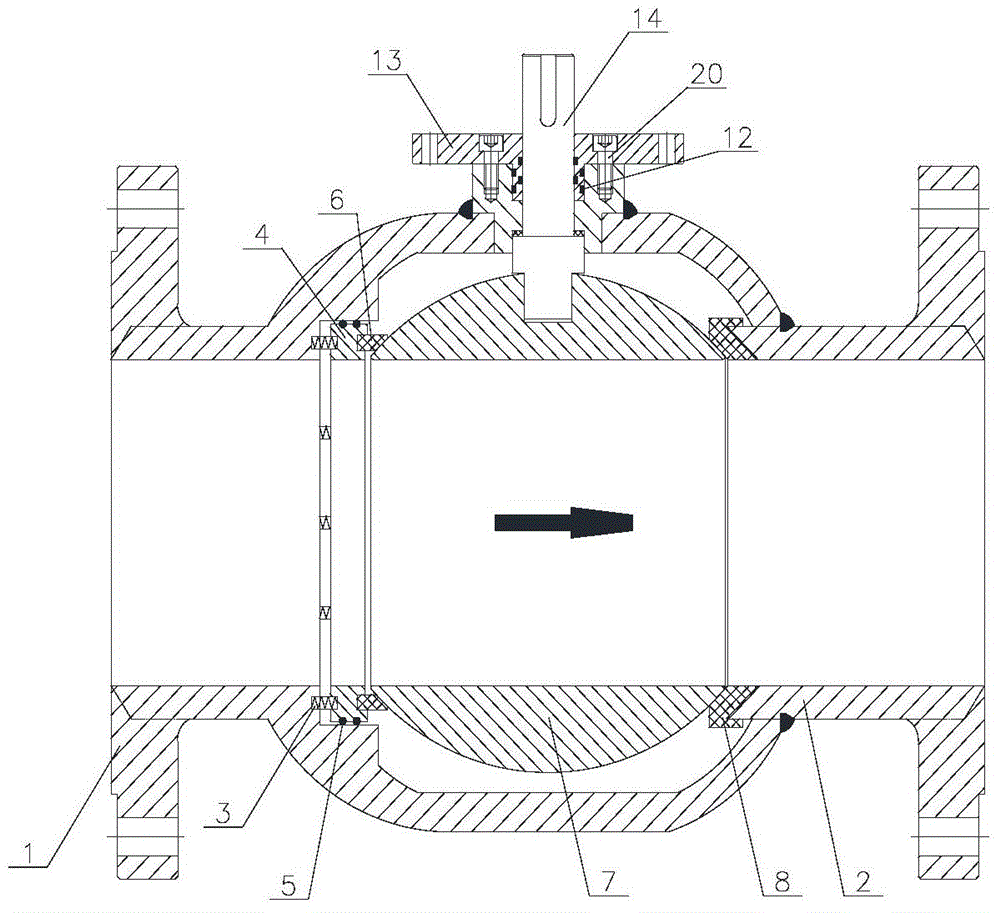

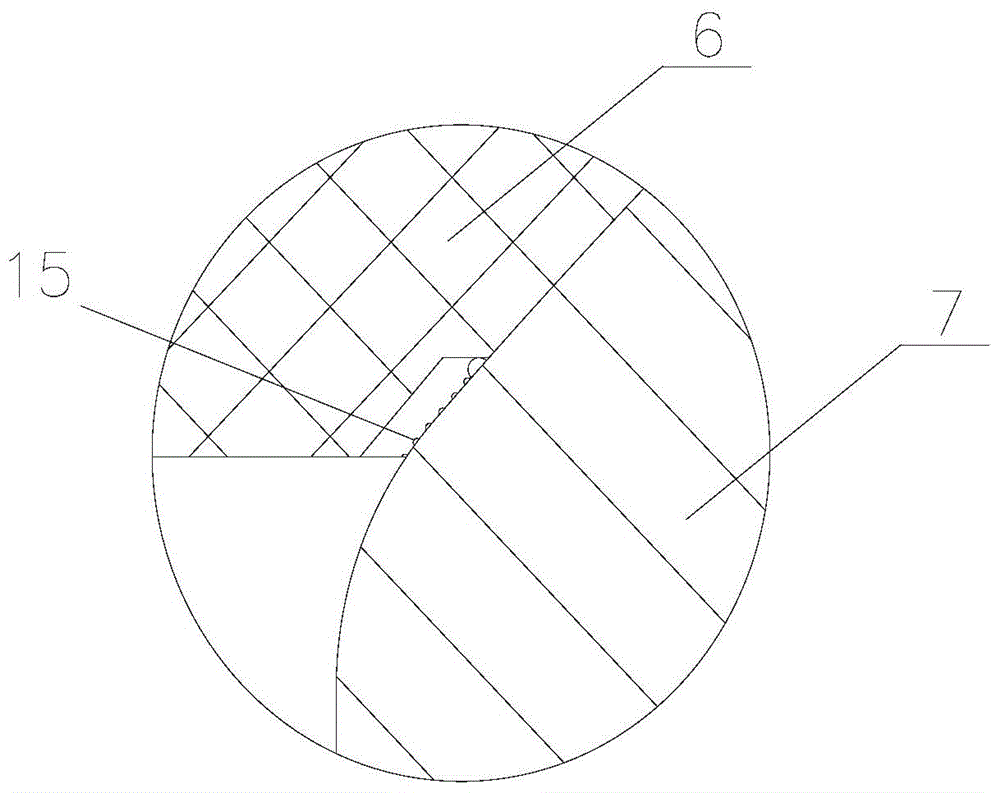

[0060] Such as figure 1 A kind of floating ball valve of the present invention shown comprises valve body, sphere (7) and switch body, and valve body comprises the inlet valve body (1) and the outlet at both ends of the sphere (7) whose axial direction is perpendicular to the axial direction of switch body (7). The valve body (2), the gasket (9) perpendicular to the axial direction of the valve body is arranged between the inlet valve body (1) and the outlet valve body (2), and the sealing device is arranged between the valve body and the ball (7). It includes a spring, an annular support ring, a valve seat and an O-ring arranged in the groove of the outer wall of the annular support ring in sequence along the axial direction of the valve body. The switch body is embedded in the outlet valve body (2), and the switch body axially It is perpendicular to the axial direction of the valve body and passes through the center of the ball (12). The inlet valve body (1) and the outlet ...

Embodiment 2

[0077] As shown in 1, a floating ball valve of the present invention includes a valve body, a ball (7) and a switch body, and the valve body includes an inlet valve body (1) at the upstream and downstream ends of the ball (7) whose axial direction is perpendicular to the axial direction of the switch body and the outlet valve body (2), a gasket (9) perpendicular to the axial direction of the valve body is provided between the inlet valve body (1) and the outlet valve body (2), and a sealing device is provided between the valve body and the sphere (7). The sealing device includes a spring arranged in sequence on the axial direction of the valve body, an annular support ring, a valve seat and an O-shaped sealing ring arranged in the groove of the outer wall of the annular support ring. The switch body is embedded in the outlet valve body (2), and the switch body axis The direction is perpendicular to the axial direction of the valve body and passes through the center of the ball ...

Embodiment 3

[0094] Such as figure 1 As shown, a kind of floating ball valve of the present invention comprises valve body, sphere (7) and switch body, and valve body comprises the inlet valve body (1) and the inlet valve body (1) and The outlet valve body (2), the gasket (9) perpendicular to the axial direction of the valve body is arranged between the inlet valve body (1) and the outlet valve body (2), and the sealing device is arranged between the valve body and the sphere (7). The device includes springs arranged in sequence on the axial direction of the valve body, an annular support ring, a valve seat and an O-shaped sealing ring arranged in the groove of the outer wall of the annular support ring. The switch body is embedded in the outlet valve body (2), and the switch body axially It is perpendicular to the axial direction of the valve body and passes through the center of the ball (12).

[0095] The inlet valve body (1) and the outlet valve body (2) are bolted.

[0096] The swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com