Boiler wet desulfurization and demisting, smoke reheating and chimney corrosion prevention integrated device and method

A technology of wet desulfurization and flue gas reheating, which is applied in the field of flue gas desulfurization, can solve the problems of reducing the entrance of desulfurization devices, low investment and operation costs, and corrosion of flue gas condensation, so as to reduce flue gas temperature, investment and operation Low cost and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are further detailed descriptions of the present invention.

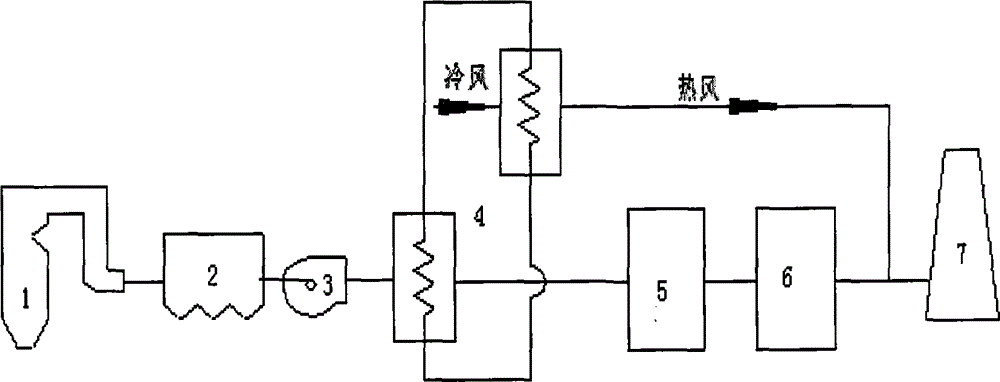

[0019] as attached figure 1 As shown, the boiler wet desulfurization and demisting flue gas reheating chimney anti-corrosion integrated device of the present invention includes a boiler 1, a dust collector 2, a suction fan 3, a desulfurization tower 5, a demisting and dehumidifying device 6 and a chimney 7, the described The device also includes a split heat pipe heat exchanger 4, which is divided into an upper heat exchange tube and a lower heat exchange tube; the boiler 1 is connected to the dust collector 2, the dust collector 2 is connected to the suction fan 3, and the suction fan 3 It is connected with the lower heat exchange tube, the lower heat exchange tube is connected with the desulfurization tower 5, the desulfurization tower 5 is connected with the demisting and dehumidifying device 6, the defogging and dehumidifying device 6 is connected with the chimney 7, and the upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com