Self-rotating type pipe-blocking prevention rubber ball

An anti-blocking tube and rubber ball technology, which is applied in the field of cleaning rubber balls, can solve the problems of rubber ball blocking the tube and high resistance of the rubber ball, and achieve the effects of preventing pipe blocking, reducing resistance and increasing ball collection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

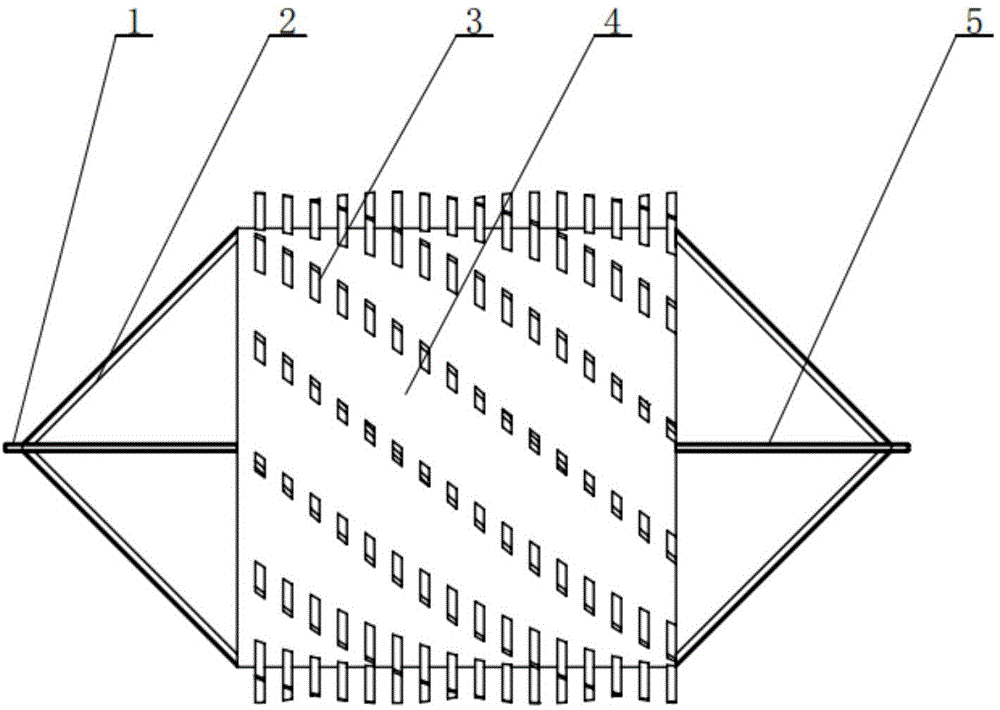

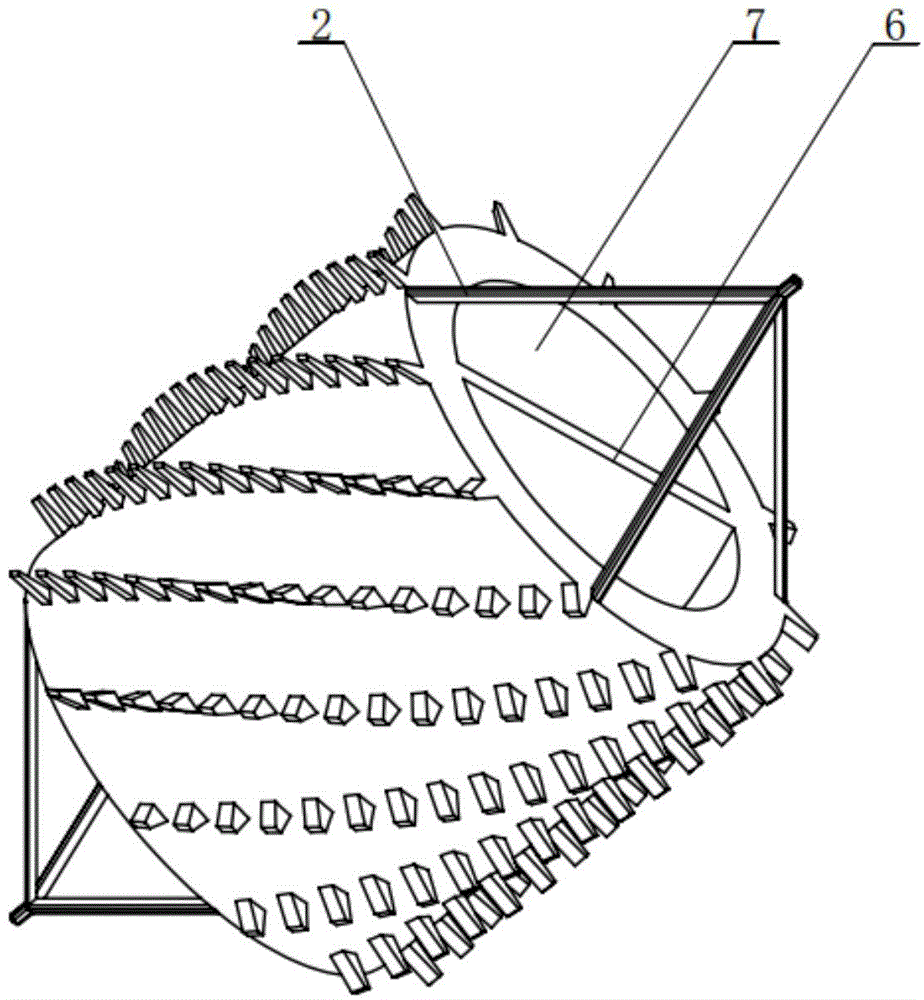

[0015] figure 1 with 2 Shown is the self-rotating anti-blocking pipe rubber ball of the present invention, which is mainly composed of piercing parts 5 at both ends and a rubber ball main body 4 . The piercing part 5 is composed of a bracket 2 and a front end protrusion 1. The parts of the bracket 2 away from the rubber ball main body 4 are in contact with each other and are tapered, and the front end protrusion 1 is the tip of the cone. The main body 4 of the rubber ball is cylindrical, the outer surface has surface protrusions 3 arranged in a spiral shape, and the inner hole 7 and spiral inner blades 6 are arranged inside.

[0016] The self-rotating anti-blocking pipe rubber ball of the present invention, when the rubber ball runs with the circulating water, when encountering plastic cloth or weeds blocking the nozzle of the heat exchange tube, the front end of the puncture part 5 of the rubber ball protrudes 1 thorn Break the plastic cloth or penetrate into the weeds, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com