Method for measuring wind driven generator air gap through eddy current sensors

A technology of eddy current sensors and wind power generators, applied in the field of measurement, can solve the problems of high price, lower sensor sensitivity, and small capacitance of capacitive sensors, reduce manufacturing or purchase costs, improve air gap control accuracy, and improve air Effect of Gap Measurement Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

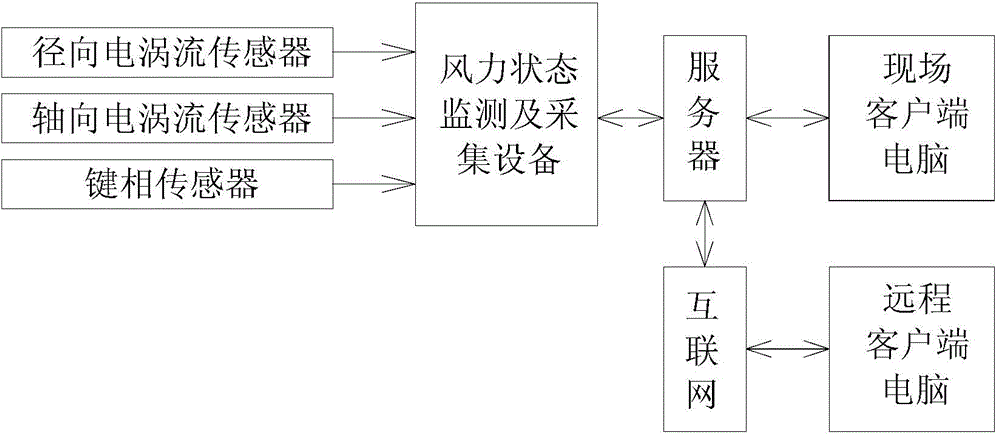

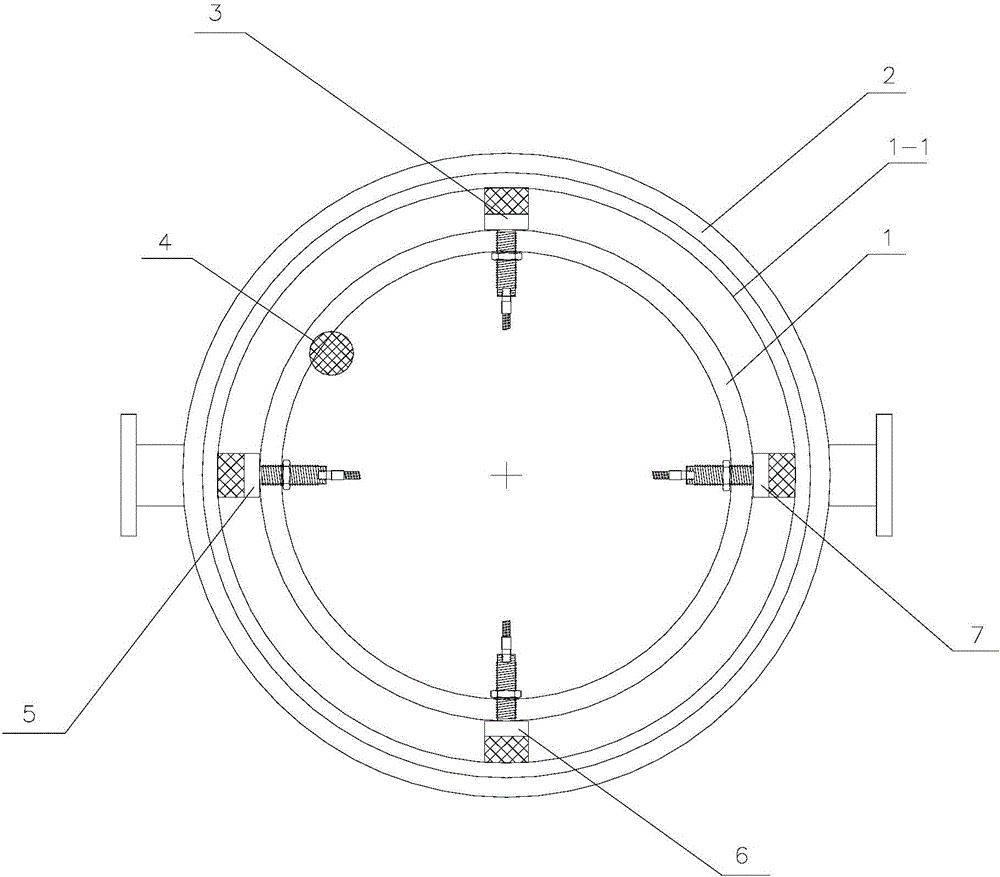

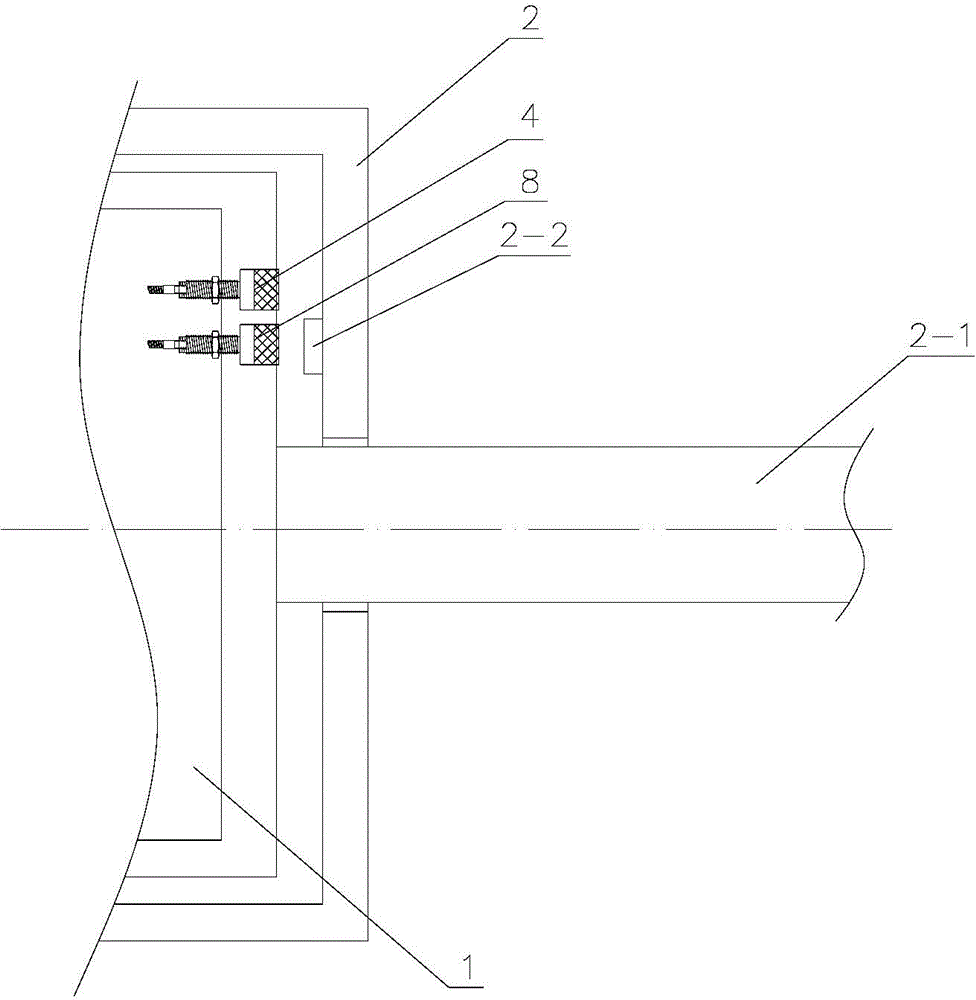

[0054] figure 1 , figure 2 and image 3 Among them, the technical scheme of the present invention mainly relies on the advantages of non-contact, high linearity, and high resolution of the eddy current sensor, and installs it on the stator of the wind turbine to statically and dynamically measure the distance between the rotor and the stator of the wind turbine. The absolute and relative displacement values.

[0055] The present invention mainly uses the eddy current sensor developed and produced by the applicant (ultra-low temperature drift type, collectively referred to as the eddy current sensor) to assist the wind power state monitoring and acquisition equipment produced by the applicant's enterprise to measure the air gap of the wind turbine.

[0056] The specific content is as follows:

[0057] One, the air gap monitoring sensor part of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com