Manufacturing method for curved surface display

A manufacturing method and display technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as color shift and affect the image display quality of the device, and achieve the effect of improving the phenomenon of color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

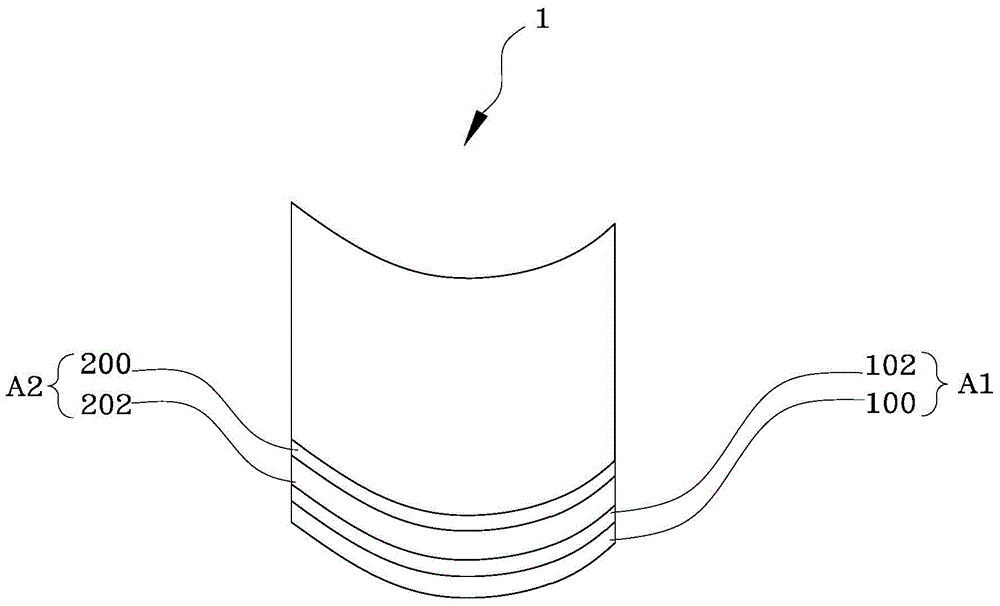

[0033] In a specific embodiment, the manufacturing method further includes: pre-bending the thin film transistor glass 102 so that the curved surface after bending corresponds to the curvature of the shape of the first curved glass 100 . The color filter glass 202 is pre-curved so that the curved surface corresponds to the curvature of the second curved glass 200 . Preferably, the respective curvatures of the first curved glass 100 and the second curved glass 200 are equal.

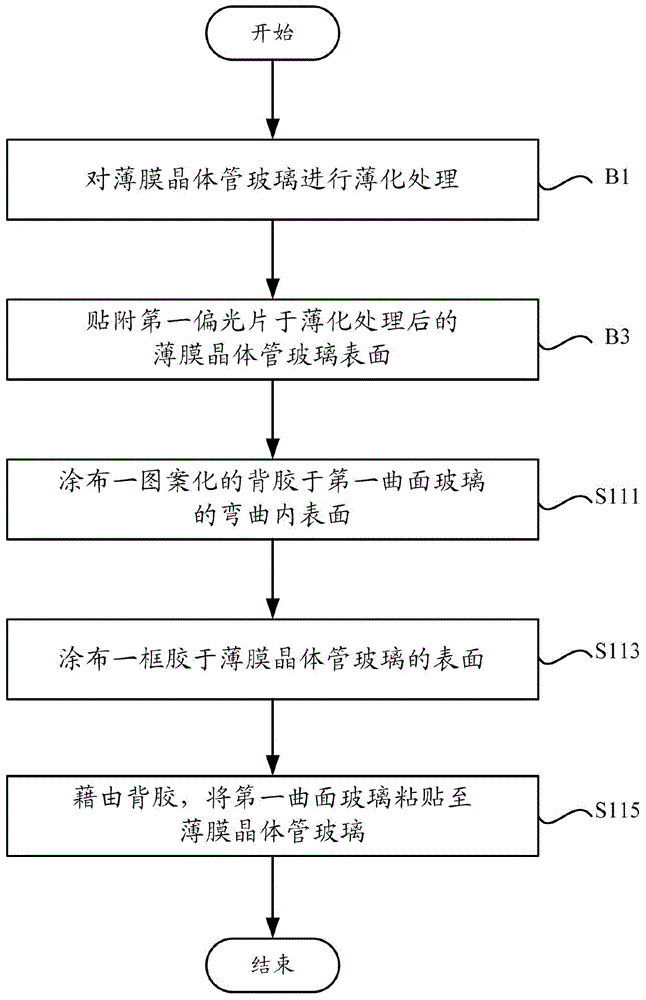

[0034] In a specific embodiment, the manufacturing method further includes: before forming the first component A1, thinning the thin film transistor glass 102 first, and then attaching a first polarizer to the thinned thin film transistor glass 102 surface. In addition, before forming the second component A2 , the color filter glass 202 may be thinned first, and then a second polarizer is attached to the surface of the thinned color filter glass 202 .

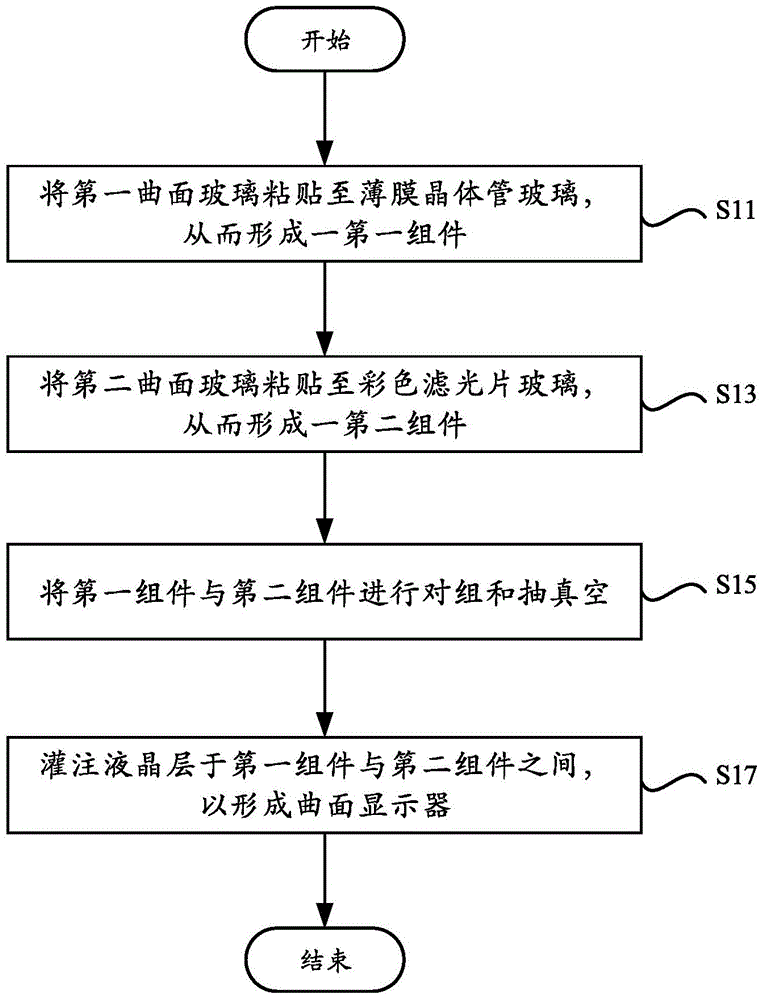

[0035] image 3 shown in figure 2 In the manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com