Safety monitoring substation for coal mine

A technology for monitoring substations and coal mine safety. It is applied in the directions of comprehensive factory control, comprehensive factory control, and electrical program control. It can solve problems such as low measurement accuracy, incomplete detection types, and poor communication reliability, and achieve convenient operation and reduce downhole Accident probability, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

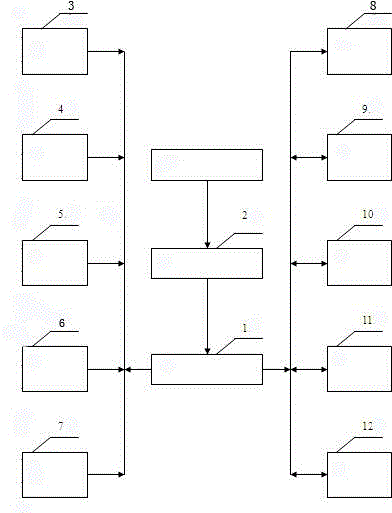

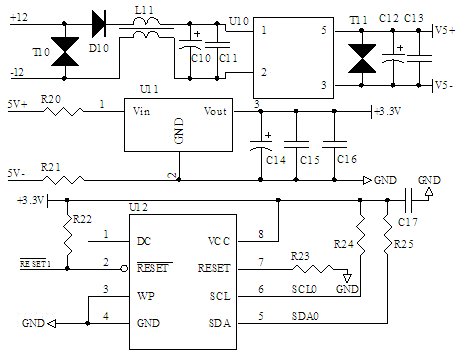

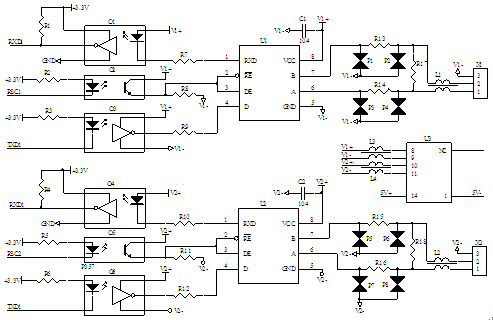

[0017] Such as figure 1 and image 3 As shown, the coal mine safety monitoring substation includes an ARM central processing unit 1, a keyboard input unit 3, an analog input unit 5, a switch input unit 6 and ISP programming interface 7, switch value output unit 10, liquid crystal display unit 11, power monitoring unit 12 and communication unit connected with the output end of said ARM central processing unit 1 through an interface circuit, said communication unit adopts RS485-1 communication unit 8 and RS485-2 communication unit 9 two mutually independent communication systems, which are respectively connected to the host computer and 20 kinds of lower-position bus-type sensors. The ARM central processing unit 1 is connected to the intrinsically safe DC power supply through the mainboard power supply unit 2. The analog quantity input unit 5 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com