Thin-wall fusion target chamber for Z-pinch driven fusion-fission hybrid power reactor

A hybrid energy and fusion target technology, which is applied in the field of fusion target chambers, can solve problems such as heat ablation resistance and thermodynamic shock requirements, and achieve the effects of improving safety margin, safety, and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

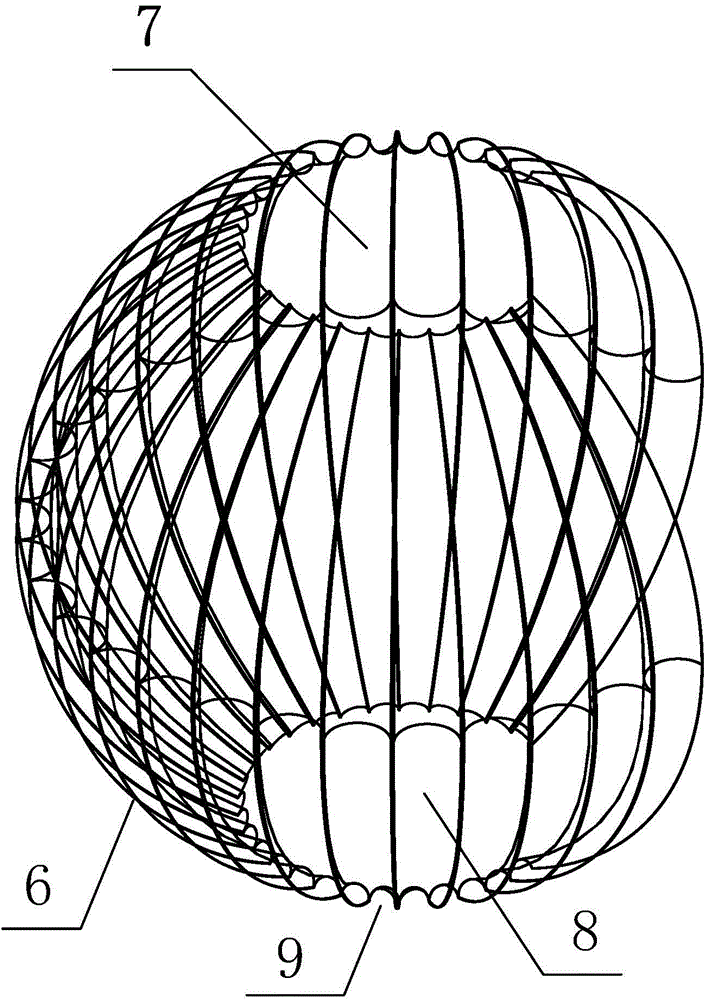

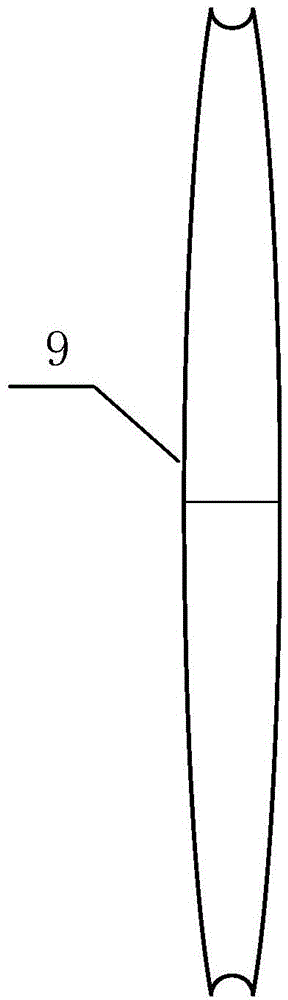

[0055] refer to Figures 1 to 6 As shown, a thin-walled fusion target chamber for a Z-pinch fusion-fission hybrid energy reactor includes a target chamber surrounded by the first wall 6 facing the plasma, and the inner wall surface of the first wall 6 facing the plasma is provided with a heat-resistant The ablation protection layer 5, the target chamber is a spherical shell structure, the upper end is provided with a refueling passage opening 7, and the lower end is provided with a waste removal passage opening 8; The center of the body structure and the wastes are moved out of some faces at three points in the center of the channel opening 8 to be divided to form some structural units 9 (the divided planes are Figure 6 As shown in the longitudinal sectional view), the spherical shell structure of the target chamber is formed by the splicing of the several structural units 9, and the cross section of the structural units 9 is arc-shaped, and protrudes toward the inside of the...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, the difference being that the radius of the target chamber is 8m, and the first wall facing the plasma is Ti with a thickness of 1cm. 3 Al alloy, the heat-resistant ablation protective layer is 0.1mm W, the target chamber is composed of 36 structural units evenly spliced, the cross-section of the structural units is arc-shaped, the radius of curvature is 0.7m, and the interior of the target chamber is filled with 1000Pa Ar gas. Under the condition of 1.5GJ fusion energy release, the radiation energy density on the inner surface of the first wall is calculated to be 0.05J / cm by using the calculation program of the radiation hydrodynamic model 2 , less than the ablation limit of W coating, the impact strength received by the first wall at the same time is 0.24MPa. Using ANSYS14.0 finite element analysis software to calculate the internal impact pressure of 1MPa, the peak value of the internal stress intensity of the f...

Embodiment 3

[0059] This embodiment is basically the same as Embodiment 1, the difference being that the radius of the target chamber is 7m, the first wall facing the plasma is a TiAl alloy with a thickness of 1.5cm, and the heat-resistant ablation protection layer is a W-10%Re alloy of 0.15mm. The target chamber is composed of 30 structural units evenly spliced. The cross-section of the structural units is arc-shaped with a radius of curvature of 0.7m. The interior of the target chamber is filled with 2000Pa of Ar gas. Under the condition of 1.5GJ fusion energy release, the radiation energy density on the inner surface of the first wall is calculated to be 0.06J / cm by using the calculation program of the radiation hydrodynamic model 2 , less than the ablation limit of W coating, the impact strength received by the first wall at the same time is 0.3MPa. Using ANSYS14.0 finite element analysis software, it is calculated that under the condition of 1MPa internal impact pressure, the peak val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com