Class 1e control cable for mild environment of third-generation passive nuclear power plant and production method

A technology for controlling cables and nuclear power plants, applied in the manufacture of insulated cables, cables/conductors, cables with double-stranded/quad-stranded, etc. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] First of all, it should be pointed out that what is described in this section is only a preferred embodiment for implementing the present invention, and those skilled in the art can make modifications to the technical solutions described here without changing the principle of the present invention. These modifications will also fall within the scope of the present invention.

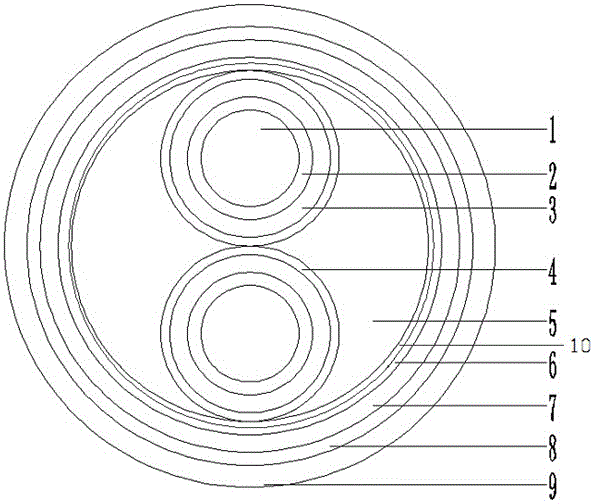

[0030] Reference attached figure 1 , third-generation passive nuclear power plant mild environment 1E level control cable, including a conductor 1, the outer wall of the conductor 1 is extruded with an inner insulating layer 2 and an outer insulating layer 3 and wrapped with a tape to form a core, and multiple cores are placed in the filler 5 are twisted into a cable core, and the cable core is sequentially provided with a tape layer 6, a composite shielding layer 7, a wrapping layer 8 and a sheath layer 9 from the inside to the outside.

[0031] In this embodiment, the conductor 1 is made of twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com