Temperature compensation method for LED drive power supply

A technology of LED driving and temperature compensation, which is applied in the direction of electric light source, light source, lamp circuit layout, etc., can solve the problems of restricting the development of LED lighting industry, unable to make cooling improvement measures, and shortening life, so as to reduce luminous flux and power consumption, avoid Effects of light decay and shortened service life, reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with accompanying drawing:

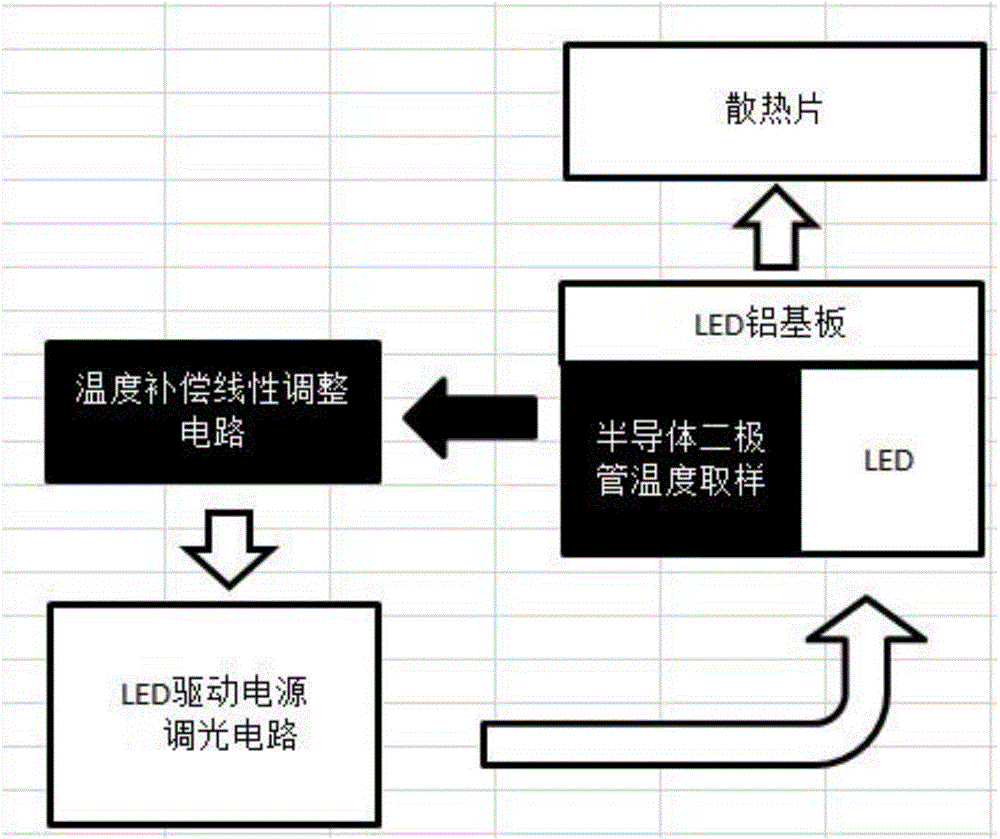

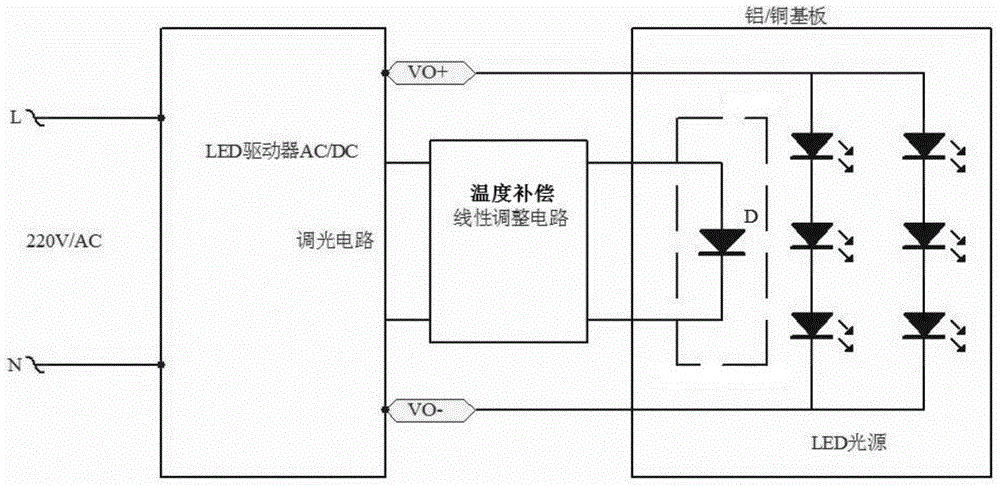

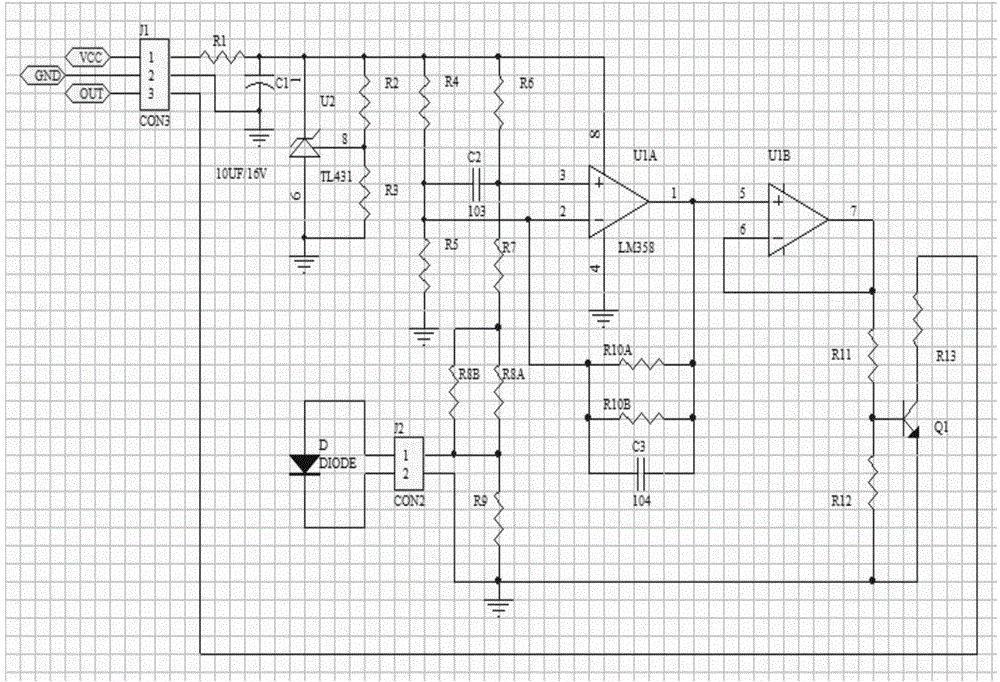

[0011] Such as Figure 1-3 As shown, the method for temperature compensation of the LED driving power supply includes the following steps: the semiconductor diode D is implanted in the LED light source module and packaged together on the LED aluminum substrate, the LED driver outputs to the LED light source module, and the LED light source The heat generated on the module is conducted to the LED aluminum substrate through the heat-conducting material, and finally dissipated into the atmosphere through the heat sink; the semiconductor diode D is used as a temperature probe. When the external heat dissipation environment is bad, the temperature of the LED light source module will reach the temperature set by the temperature compensation system. After the semiconductor diode D gets the feedback information, it is connected to the LED drive power dimming circuit for real-time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com