Laminate containing coated polyester film

A laminated material, polyester film technology, applied in the field of laminated material, polyester film, coated polyester film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

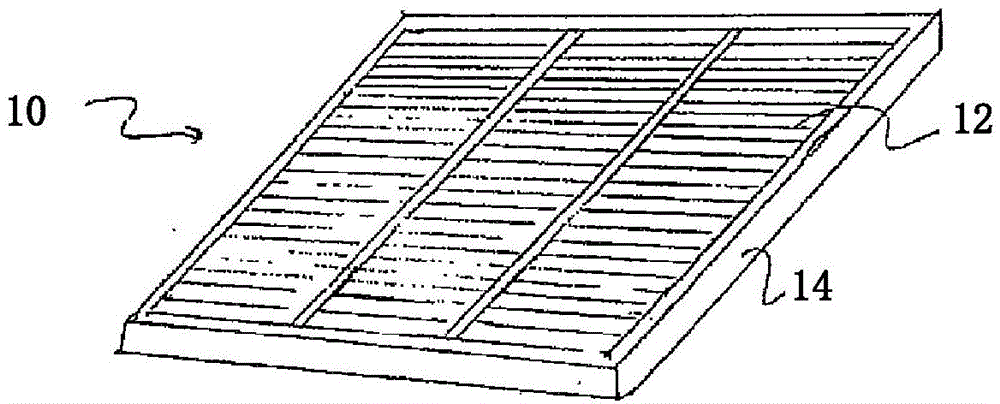

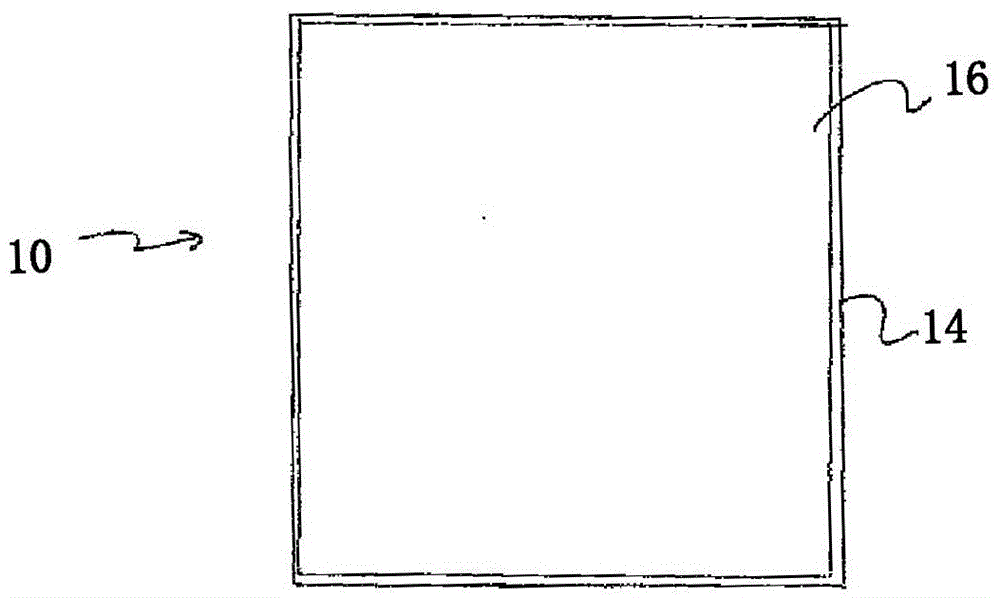

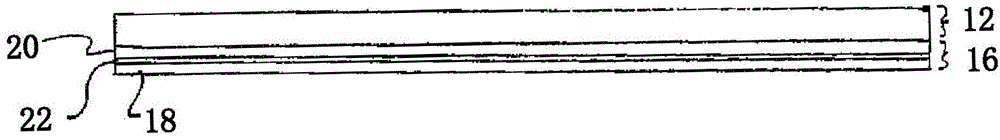

Image

Examples

Embodiment 1

[0083] PET pellets filled with 18% barium sulfate were introduced into a single screw extruder where they were heated and compressed into a molten state. The melt was extruded through a slot die and cast on casting rolls maintained at about 20°C where it solidified into an amorphous preparation film. The preliminary film was stretched longitudinally at 95° C. at a stretch ratio of 3.6:1. The stretched film was passed under a corona treater (Enercon Industries) at 1.5 W / ft 2 .min for corona treatment. Subsequently, an aqueous dispersion containing 20% by weight solids (based on dry coating, which contained 50% by weight of Michem Prime 4983R (Michelman) ethylene-acrylic acid copolymer dispersion and 50% by weight of EPOCROS WS700 (Nippon Shokubai, Japan) oxazoline crosslinker) to coat the longitudinally stretched film over a reverse gravure roll. The longitudinally dried film was then dried at about 100° C. and then stretched transversely at a stretch ratio of 4.3:1 to obt...

Embodiment 2

[0086] PET pellets filled with 18% barium sulfate were introduced into a single screw extruder where they were heated and compressed into a molten state. The melt was extruded through a slot die and cast on casting rolls maintained at about 20°C where it solidified into an amorphous preparation film. The preliminary film was stretched longitudinally at 95° C. at a stretch ratio of 3.6:1. The stretched film was passed under a corona treater (Enercon Industries) at 1.5 W / ft 2 .min for corona treatment. Subsequently, an aqueous dispersion containing 20% by weight solids (based on dry coating, which contained 50% by weight of Michem Prime 4983R (Michelman) ethylene-acrylic acid copolymer dispersion and 50% by weight of EPOCROS WS700 (Nippon Shokubai, Japan) oxazoline crosslinker) to coat the longitudinally stretched film over a reverse gravure roll. The longitudinally dried film was then dried at about 100° C. and then stretched transversely at a stretch ratio of 4.3:1 to obt...

Embodiment 3

[0089] PET pellets filled with 18% barium sulfate were introduced into a single screw extruder where they were heated and compressed into a molten state. The melt was extruded through a slot die and cast on casting rolls maintained at about 20°C where it solidified into an amorphous preparation film. The preliminary film was stretched longitudinally at 95° C. at a stretch ratio of 3.6:1. The stretched film was passed under a corona treater (Enercon Industries) at 1.5 W / ft 2 .min for corona treatment. Subsequently, an aqueous dispersion containing 22% by weight solids (based on the dry coating containing 15% by weight of PKHW-38 phenoxy resin (InChem Corp.) copolymer dispersion and 85% by weight of EPOCROS WS700 (Nippon Shokubai, Japan) oxazoline crosslinker) to coat the longitudinally stretched film via reverse gravure rolls. The longitudinally dried film was then dried at about 100° C. and then stretched transversely at a stretch ratio of 4.3:1 to obtain a bidirectionally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com