Lighting module and method of manufacturing a lighting module

A technology for light-emitting modules and light-emitting surfaces, which is applied to semiconductor devices, light sources, lasers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following description, the invention is described with reference to a method of manufacturing a lighting module.

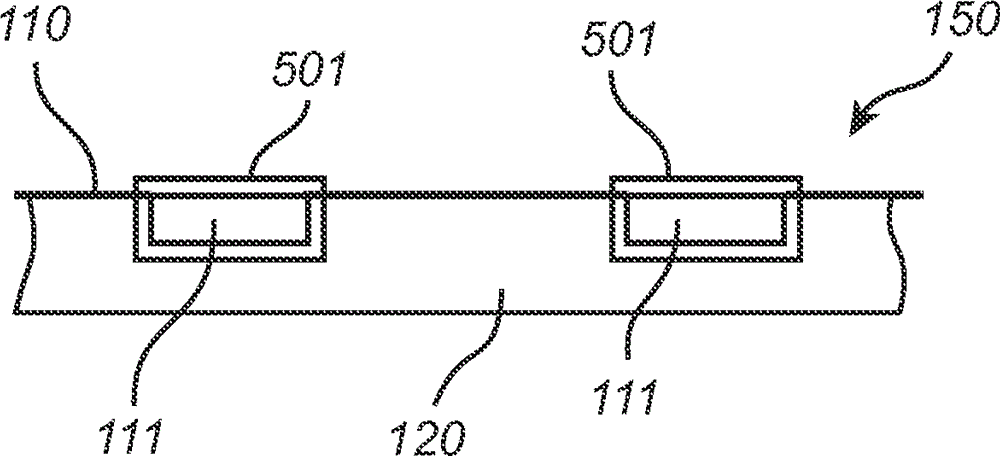

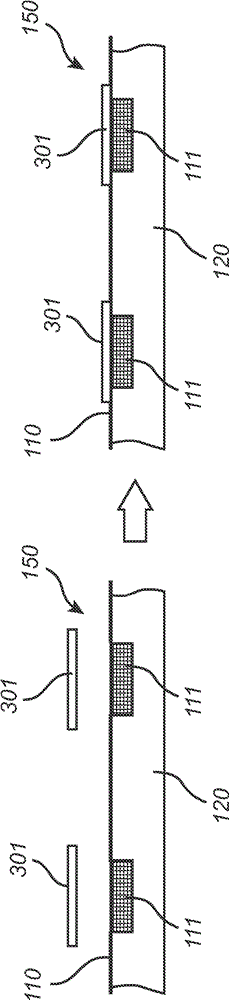

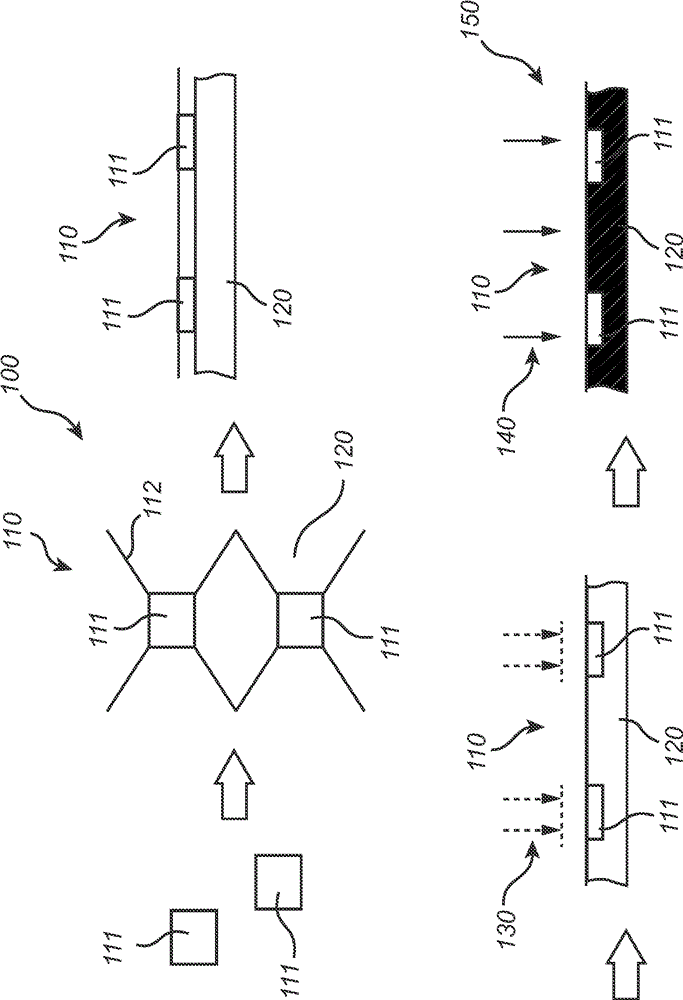

[0044] figure 1 is a schematic illustration of a method 100 for manufacturing a lighting module 150 . The method 100 includes the step of providing a light source assembly 110 comprising a plurality of light sources 111 (hereinafter denoted LEDs) electrically connected to a carrier 112 . Here, the carrier 112 is provided as a wire grid to which the LEDs 111 are connected, wherein the wire grid has a chicken wire shape. However, it will be appreciated that substantially any wire grid grid shape may be feasible. Each LED 111 has a light emitting (ie, light transmissive) surface on the top portion of the LED 111 . The method 100 further includes the step of providing a heat dissipation material 120 in a fluid state, wherein an example of the heat dissipation material 120 may be ceramic. Preferred ceramics are, for example, clay, concrete, quartz, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com