An assembled follow-up sand box and an assembling method for the follow-up sand box

An assembled and shape-dependent technology, applied in mold boxes, casting equipment, metal processing equipment, etc., can solve the problems of long sand molding time, slow cooling speed, and high production costs, and achieve the optimization of the internal structure of the sand box, reducing The ratio of sand to iron and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

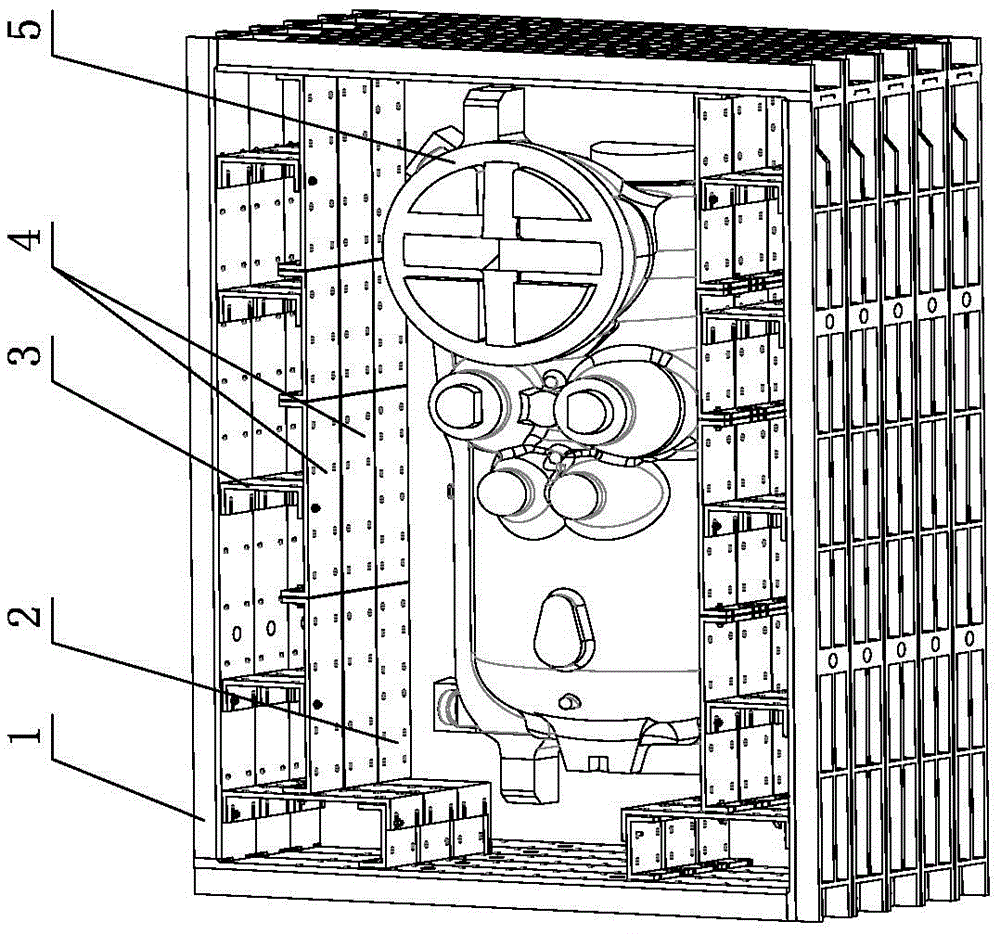

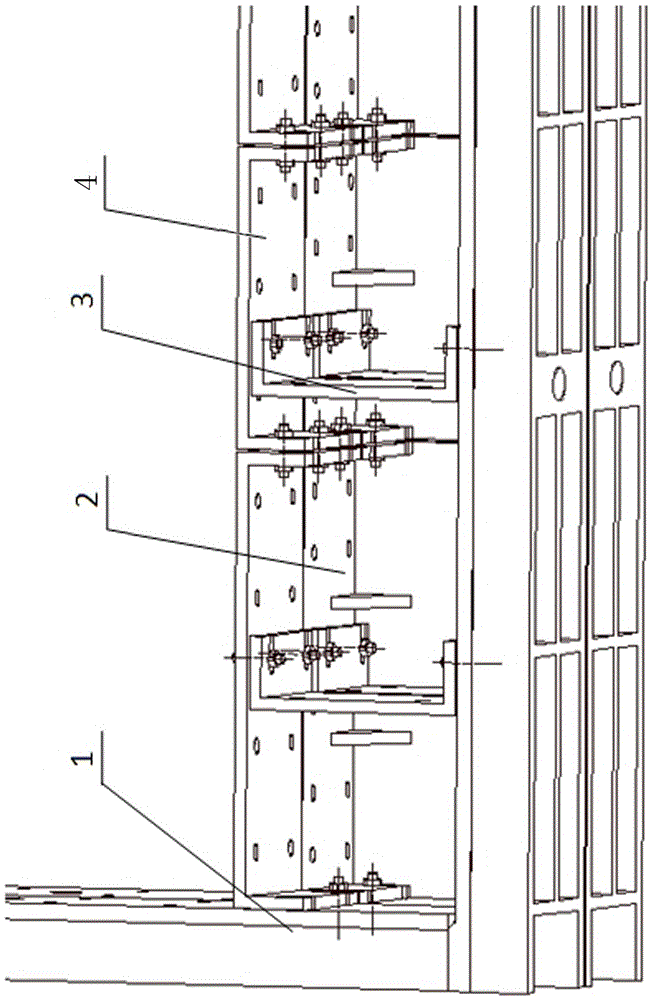

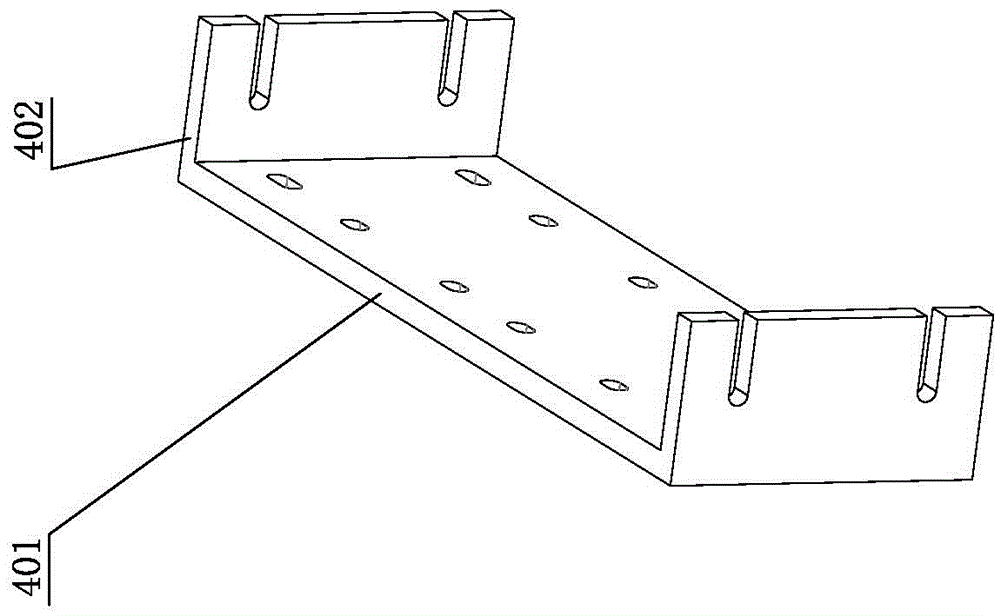

[0022] Such as figure 1 — Figure 4 Shown is the assembled type follow-up sand box of the present invention, including several stacked general-purpose sand boxes 1, which are assembled with a bottom sand barrier 2 and several layers of sand barriers assembled on the upper side of the bottom sand barrier 2. Plate 4, each bottom sand barrier 2 and upper sand barrier 4 are also fixedly connected to the support plate 3 with the general sand box 1, and the upper sand barrier 4 and the bottom sand barrier 2 are assembled and superimposed in the general sand box 1 Form the continuous inner wall of the molded sand box. For the convenience of optimizing the separation area in the general sand box 1, the upper layer sand barrier 4 and the bottom sand barrier 2 have the same height as the general sand box 1 of each layer. Specifically, the upper layer sand barrier 4 includes a The side plate 401 of the side plate 401 and the end plate 402 vertically arranged at both ends of the side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com