Slate grinding treatment device

A processing device and slate technology, applied in grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve problems affecting the physical and mental health of employees, reduce production efficiency, and heavy grinding dust, etc., and achieve simple structure and high production efficiency. The effect of improving efficiency and improving work enthusiasm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

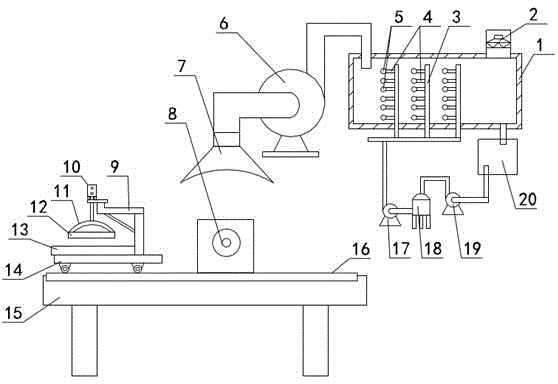

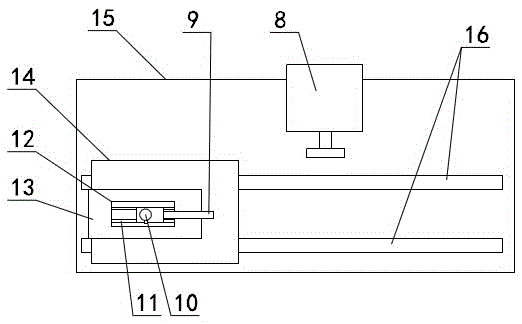

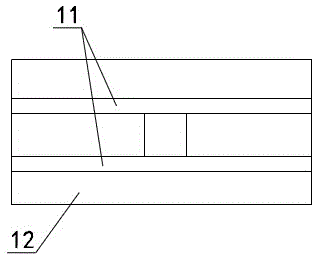

[0022] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the slate grinding treatment device includes a workbench 15, a grinding machine 8 and a mobile trolley 14, on the workbench 15 a guide rail 16 for moving the trolley 14 left and right is installed, on the mobile trolley 14 is provided with a slate installation block 13, A matching pressing plate 12 is arranged above the slate mounting block 13, and a power mechanism for the up and down movement of the pressing plate 12 is provided on the mobile trolley 14 corresponding to the pressing plate 12. The power mechanism includes a bracket 9, a hydraulic cylinder 10 and a push frame of a frame structure. 11. The push frame 11 is fixed on the pressure plate 12, the cylinder body of the hydraulic cylinder 10 is installed on the bracket 9, the piston rod of the hydraulic cylinder 10 is fixed to the push frame 11, the bracket 9 is installed on the mobile trolley 14, and the grinding machine 8 is set above There is...

Embodiment 2

[0026] This embodiment is changed on the basis of Embodiment 1. A telescopic hydraulic cylinder 21 is installed on the left side of the workbench 15. The cylinder body of the telescopic hydraulic cylinder 21 is installed on the workbench 15. The telescopic hydraulic cylinder 21 The top of the piston rod is fixed on the left side of the mobile dolly 14; the painting main pipe 3 is changed to 2; the painting branch pipe 4 is changed to 5. Others are the same as embodiment one.

Embodiment 3

[0028] This embodiment is changed on the basis of Embodiment 1, the said painting main pipe 3 is changed into 4; the said painting branch pipe 4 is changed into 7. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com