Waste tire highway isolation belt device

A technology for waste tires and highways, applied in road safety devices, roads, roads, etc., can solve the problems of increasing road maintenance times and maintenance costs, shortening the service life of roads, consuming large water resources, etc., and achieves simple structure and low cost , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

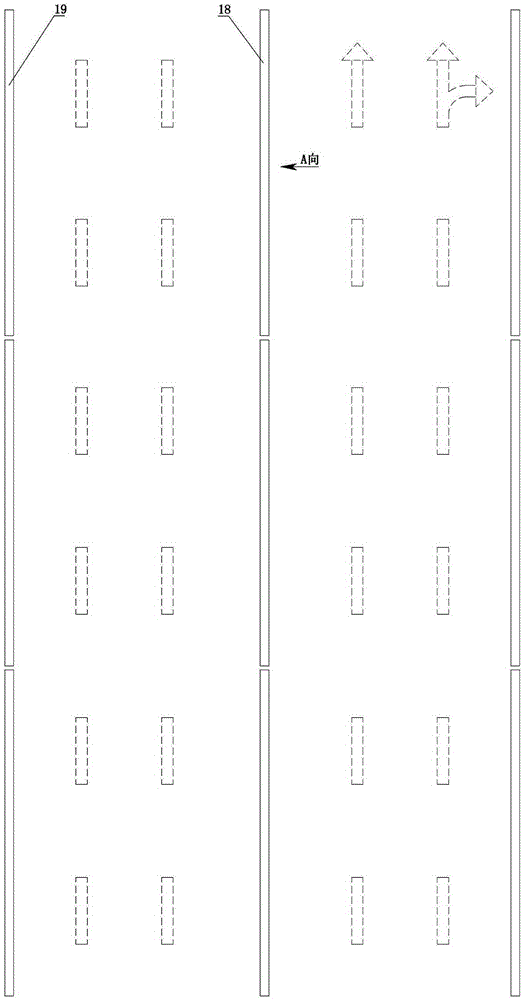

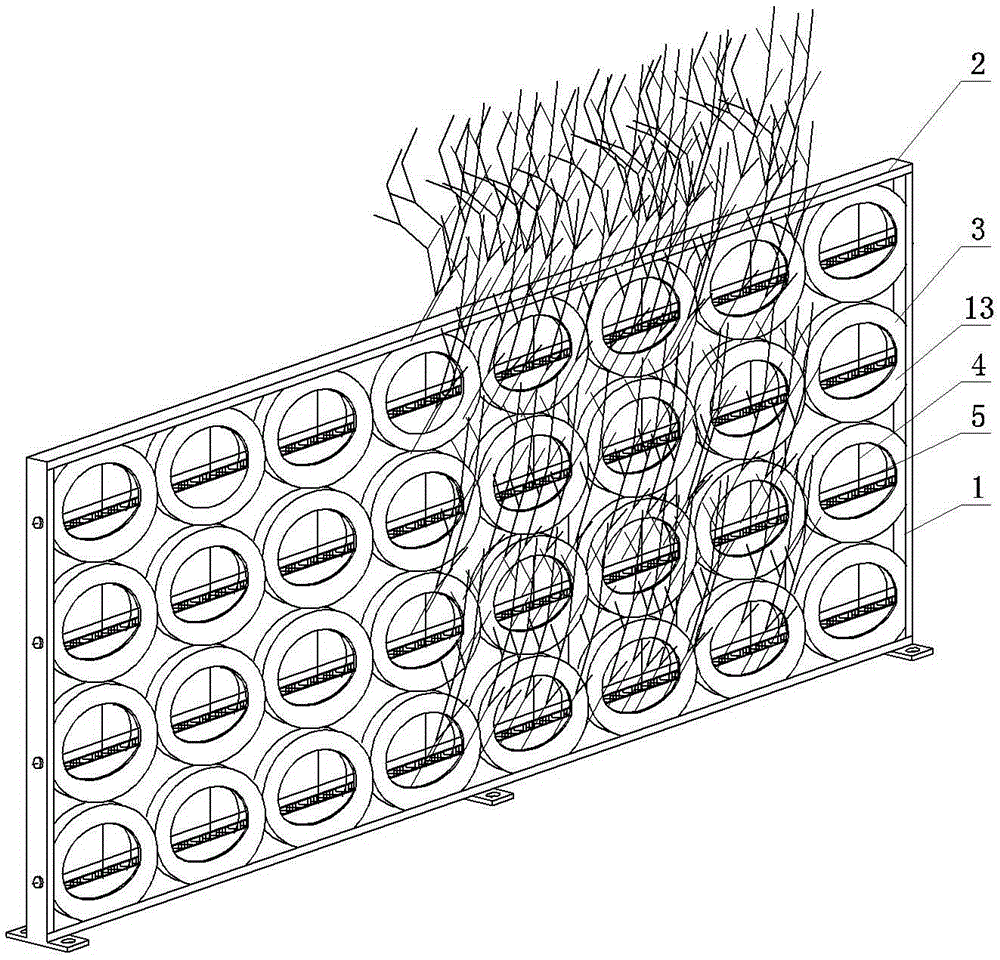

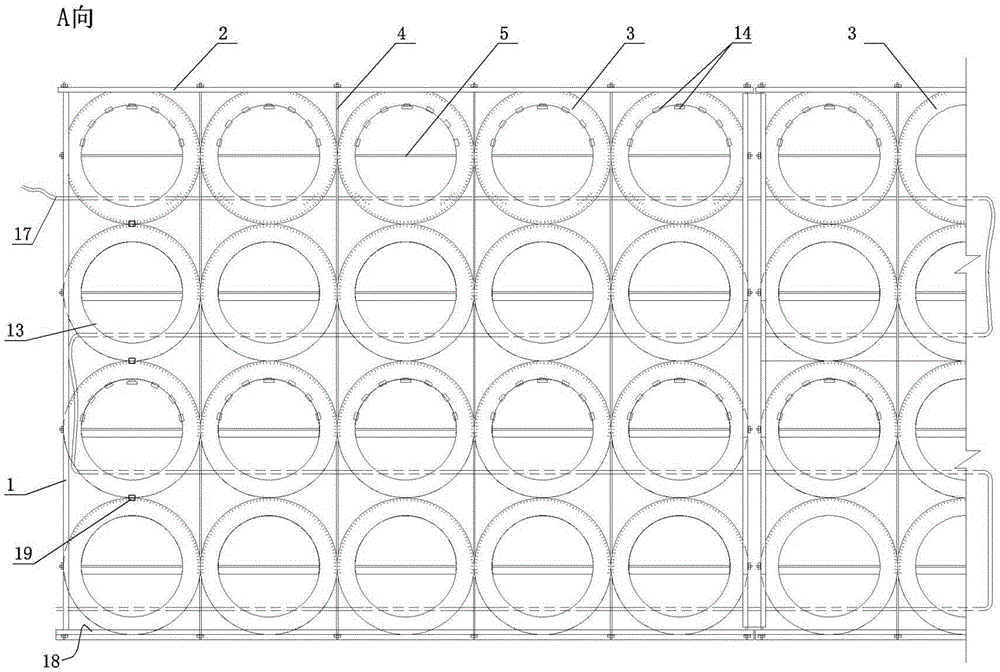

[0026] Embodiment 1: a kind of waste tire expressway barrier device, see figure 1 , figure 2 and image 3 , the frame includes left and right sides 1, a top beam 2, and a bottom beam. The frame is a frame with adjustable length and width, please refer to the specific structure Figure 4 and Figure 5, Adjusting structures are arranged between the top beam 2 and the bottom beam and the side 1 respectively. The upper and lower ends of the side are respectively provided with a frame adjustment rod 16 and a frame lock nut 15, and a strip-shaped frame adjustment hole 10 is provided at the ends of the top beam 2 and the bottom beam, and the frame adjustment rod 16 is inserted into the frame for adjustment. Inside the hole 10 , the frame locking nut 15 is located outside the frame adjusting hole 10 .

[0027] image 3 In the frame, the waste tires 3 adjacent to each other are fully filled to form the main body of the fence; the top beam, the bottom beam, and the two sides are ...

Embodiment 2

[0030] Embodiment 2: Another kind of waste tire expressway barrier device, see Figure 6 , the content is basically the same as that of Example 1, the difference is that the waste tires are arranged in different ways to form interlaced three-dimensional planting patterns. see Figure 7 and Figure 8 , a cross button 21 is fixed at the intersection of mutually perpendicular prestressed steel strands. Hinged together by a rotating shaft 24, a connecting piece 25 is respectively fixed on one side of the vertical fixing piece 22 and the horizontal fixing piece 23, and a buckle head 26 is fixed on the connecting piece 25, on the vertical fixing piece 22 and the horizontal fixing piece 23 The other side is provided with buttonhole 27, and the two sides of this buttonhole 27 are provided with draw-in groove 28 and are matched with snap ring 29, and clip spring 28 goes deep inside buttonhole 27, and described button head 26 and buttonhole 27 are matched and installed by clip spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com