Cold recovery method for vaporization heat absorption-compression heat release coupling

A cooling capacity recovery and compressor technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of large cooling capacity loss, complex recovery structure, and difficulty in cooling capacity recovery, so as to improve the heat exchange rate and increase the heat exchange rate. area, the effect of avoiding the use of large heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

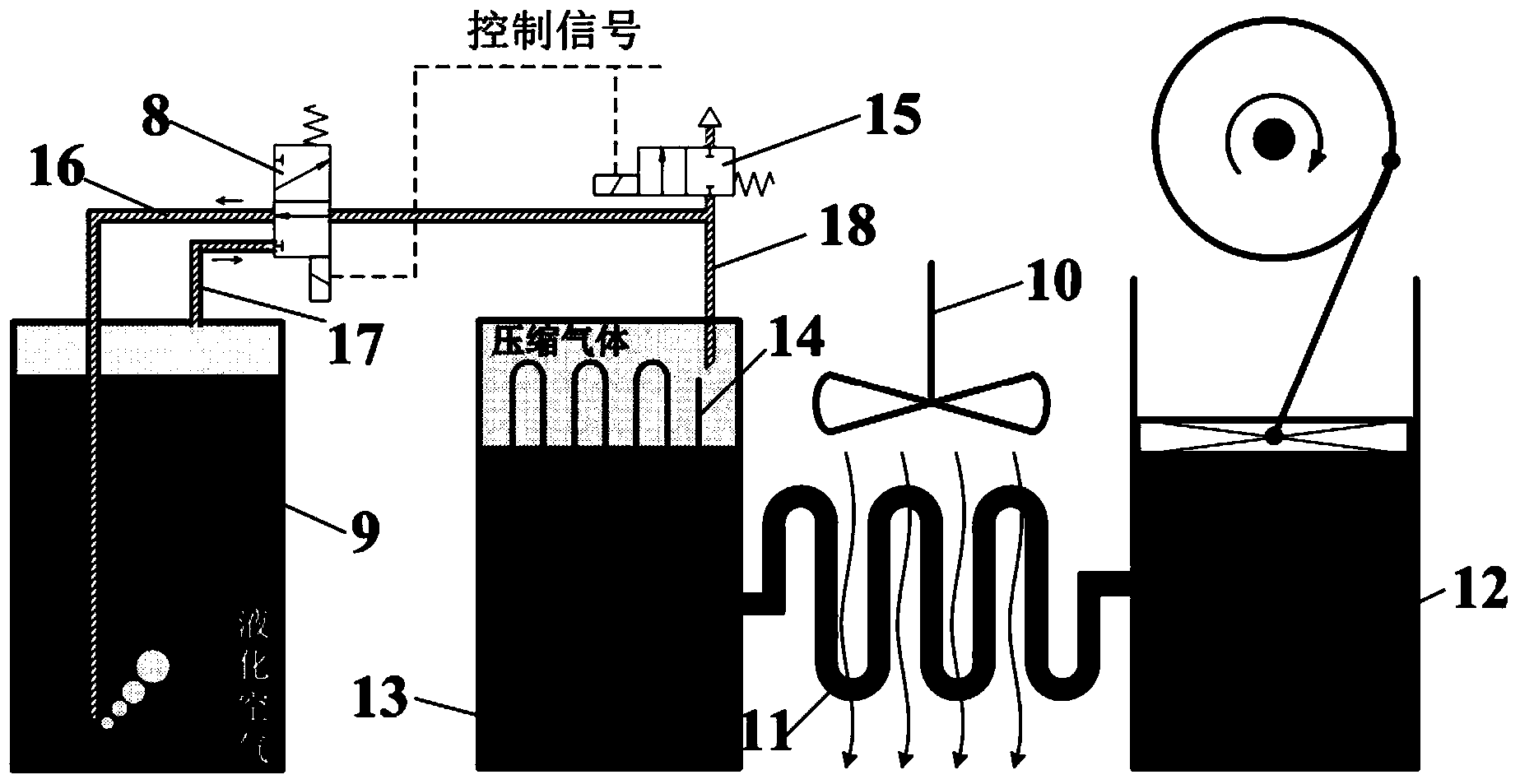

[0024] The whole system consists of a working tank (9), a heat exchange tank (13) and a piston cylinder (11). The pipeline (18) connected to the heat exchange tank (12) is divided into two branches, and two valves (8 ) is connected to the working tank (9), the other is connected to the two-position valve (15), and the injection pipe (16) connected to the two-position valve (8) is inserted into the working tank (9) once the liquid level, and connected to the two-position valve ( 8) The connected pipeline (17) is inserted above the liquid level in the working tank (9), the heat exchange tube (11) is connected in series between the heat exchange tank (13) and the piston cylinder (12), and the heat exchange tube (12) is placed outside The fan (10), the built-in heat exchanger (14) in the heat exchange tank (13) complete the gasification-compression process, expansion process and exhaust process.

[0025] Gasification-compression process: the two-position valve (8) is in the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com