Aspheric surface non-contact type measuring system and method for deflection workpieces

A non-contact, measurement system technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as difficulty in aspherical surface detection, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

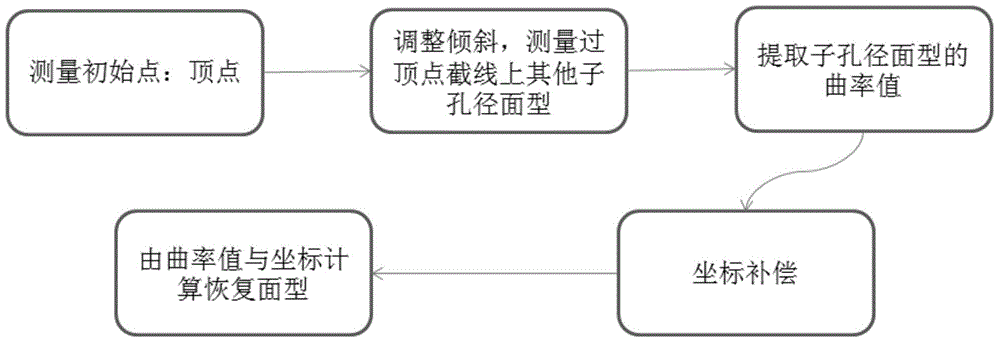

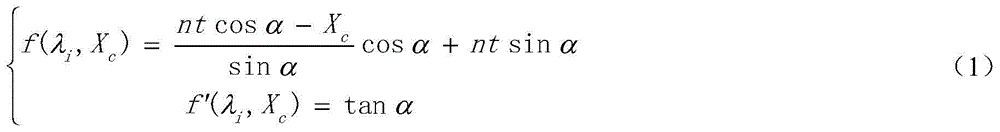

[0030] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

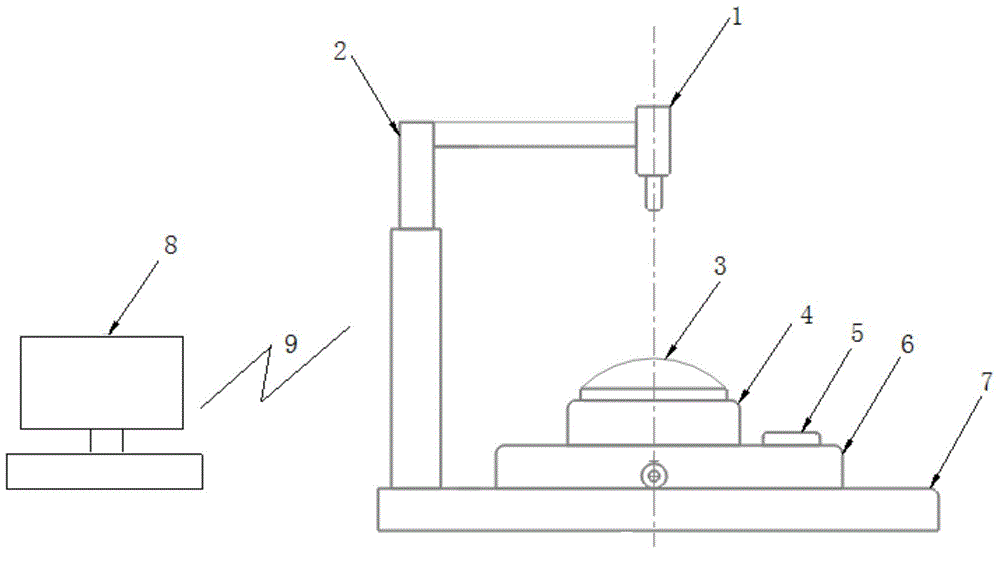

[0031] to combine figure 1 , according to a preferred embodiment of the present invention, a non-contact measurement system for deflecting the aspheric surface of a workpiece, which includes: a non-contact optical profiler probe 1, a profiler lifting adjustment mechanism 2, a precision three-dimensional translation table 4, a digital Inclinometer 5, two-dimensional tilt table 6, base 7 and a computer system 8, such as figure 1 shown, where:

[0032] The non-contact optical profiler probe 1 is fixed on the profiler lifting adjustment mechanism 2;

[0033] The precision three-dimensional translation platform 4 is fixed on the two-dimensional tilting platform 6, and is used to realize the bearing of the measured object 3 and the lateral movement and positioning of the measured object 3;

[0034] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com