Manufacturing method and temperature detection method for PbSe quantum dot liquid-core optical fiber temperature sensor

A technology of temperature sensor and quantum dot liquid, applied in thermometer testing/calibration, thermometer, thermometer with physical/chemical changes, etc., can solve the problems of fluorescent material lifespan affected by environmental factors, low quantum yield, high cost, etc. Achieve the effect of low cost, high quantum yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The details of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the following examples.

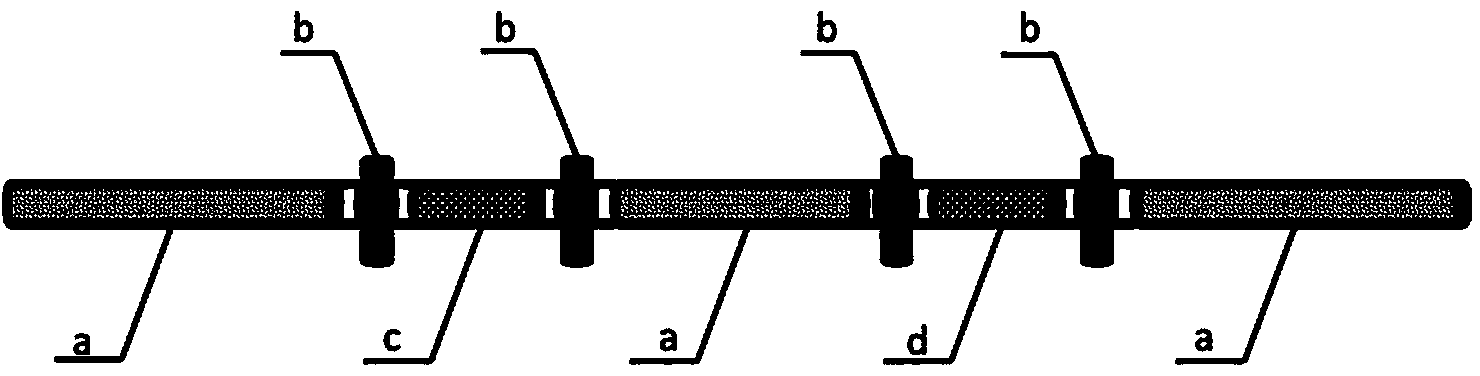

[0041] The embodiment of the present invention describes the two-point colloidal PbSe quantum dot liquid core optical fiber temperature sensor and its two-point temperature detection method.

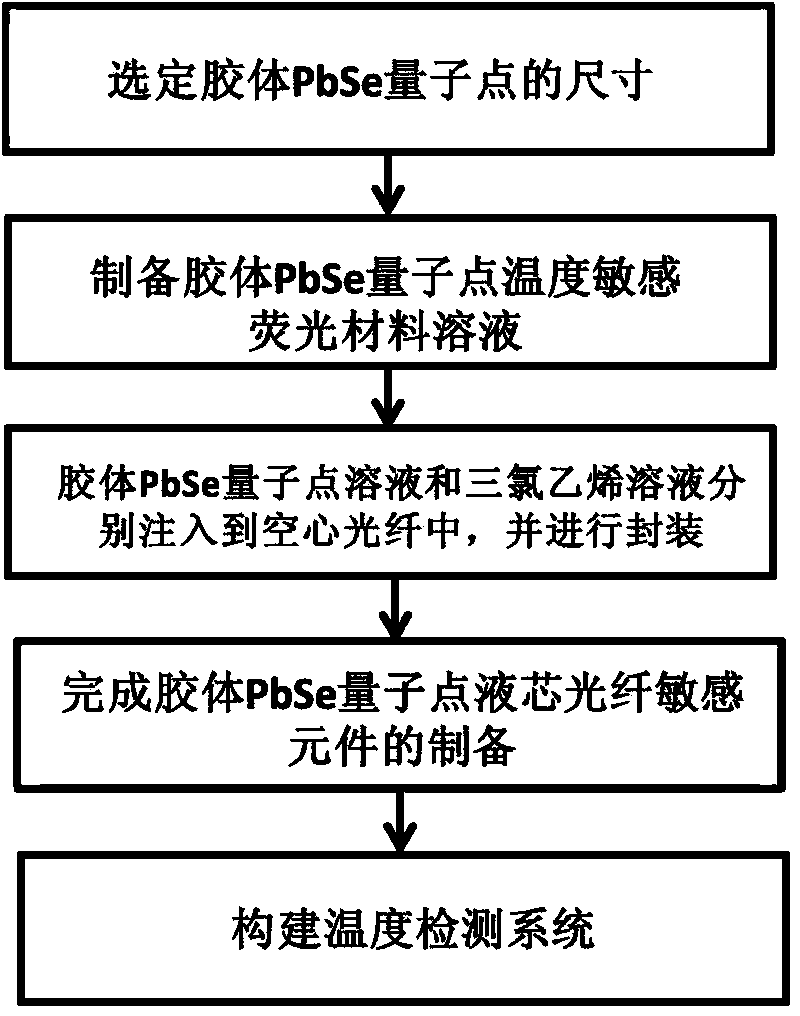

[0042] 1. Combination figure 1 and figure 2 , the preparation method of the liquid core optical fiber sensitive element of the colloidal PbSe quantum dot two-point temperature of the present invention and the preparation method of the two-point type colloidal PbSe quantum dot liquid core optical fiber temperature sensor are as follows:

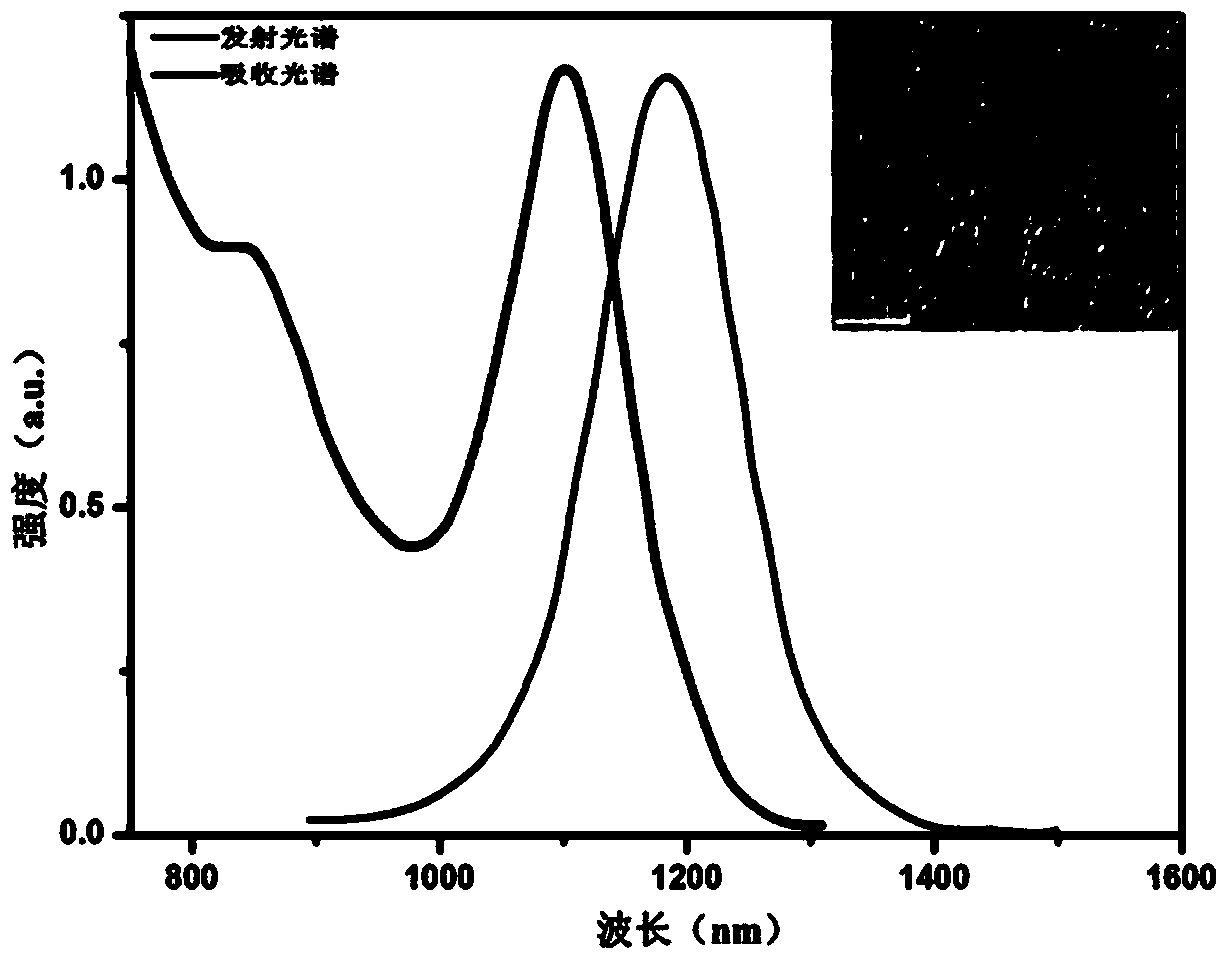

[0043] The first step is to select the size of two colloidal PbSe quantum dots. The present invention selects In 0.53 Ga 0.47 As / InP PIN photodiode is used as a detector, and its acceptable wavelength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com