A liquid metal cooling reactor experimental system capable of realizing critical and subcritical operation experiments

A liquid metal cooling and experimental system technology, applied in the field of liquid heavy metal natural circulation cooling reactor experimental system, can solve the problems of large difference in core power density, uneven core outlet temperature, difficult flow distribution, etc., to achieve uniform outlet temperature , avoid component instability, and reduce the cost of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

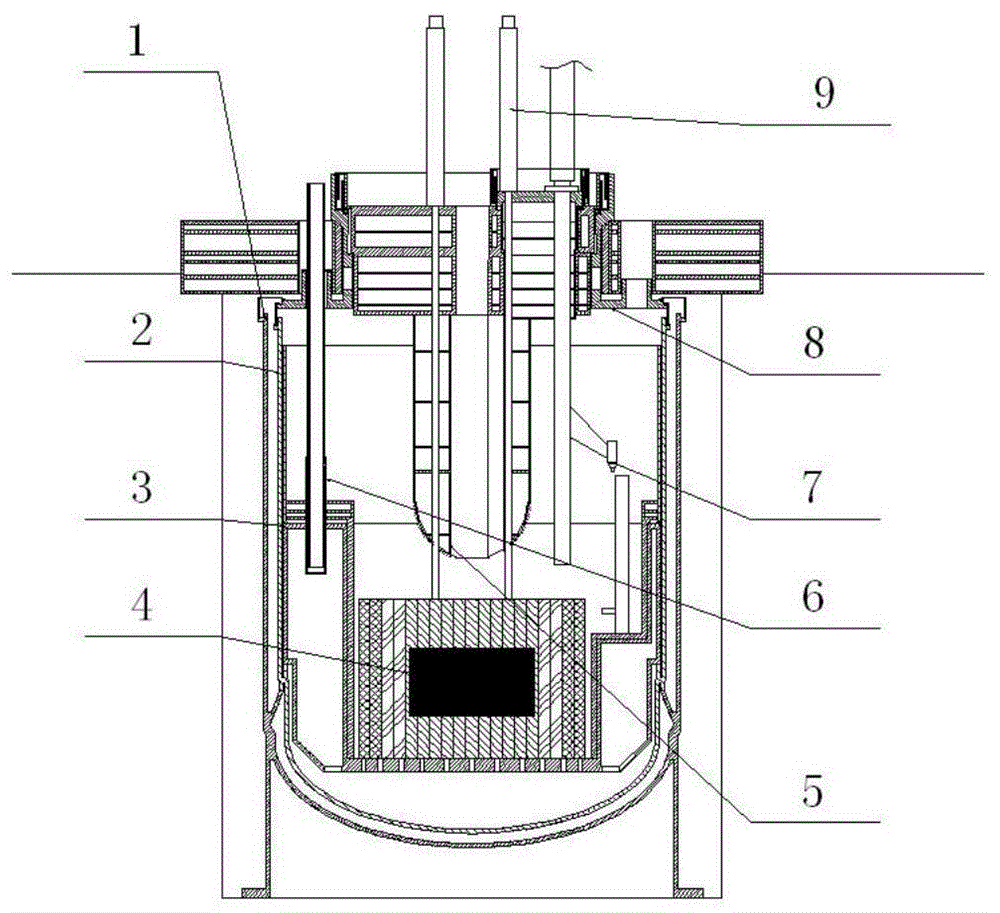

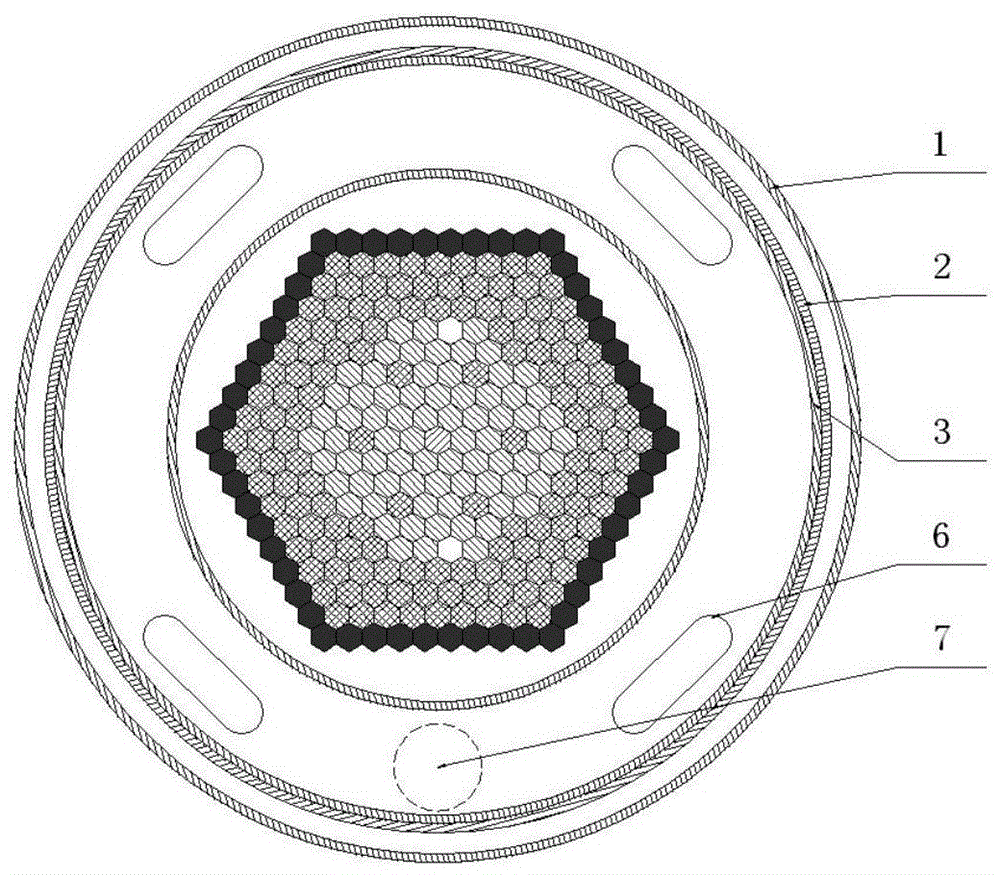

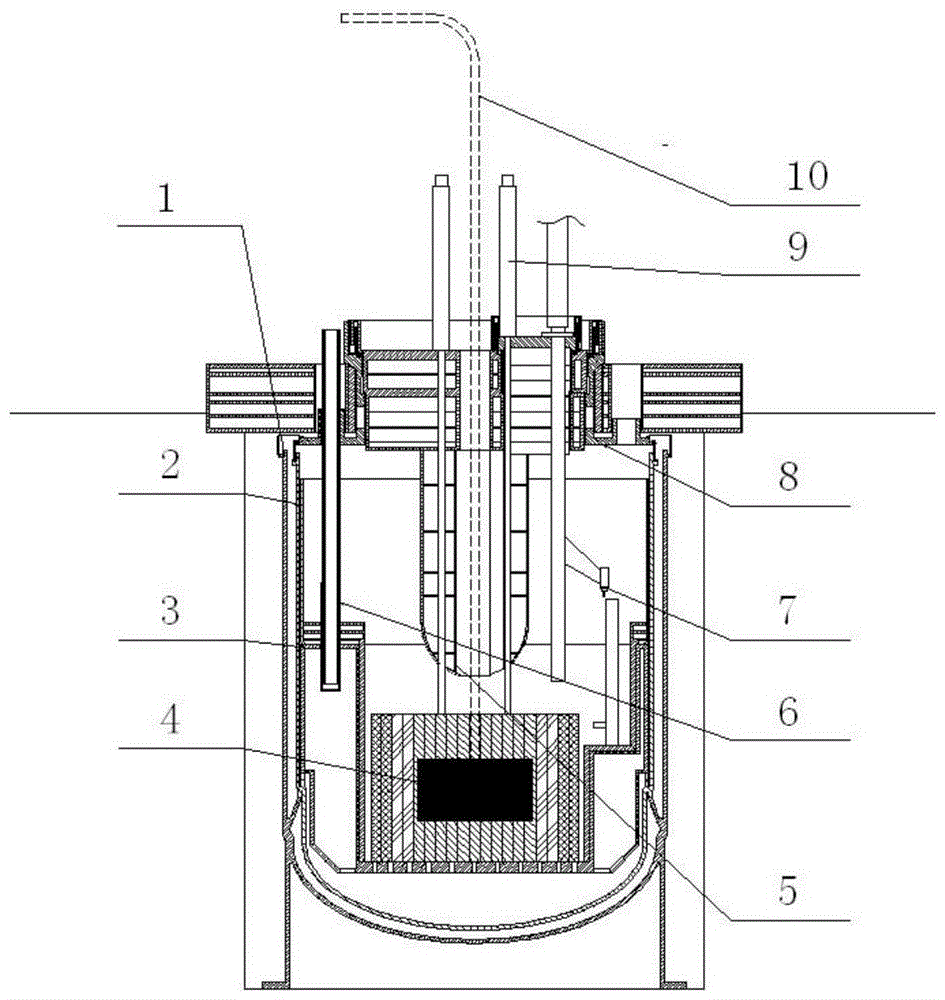

[0027] Such as figure 1 As shown, a kind of liquid metal cooling reactor experiment system that can realize critical and subcritical operation experiments provided by the present invention is composed of safety vessel 1, main vessel 2, support structure 3 in the reactor, core 4, central measuring column 5, main It consists of a heat exchanger 6, a refueling mechanism 7, a stack top cover 8, a control rod driving mechanism 9 and a neutron source 10.

[0028] The safety container 1 is composed of a cylindrical shell and a bottom head, which is similar in structure to the main container. Its function is that when the main container leaks, the safety container will contain the primary circuit coolant and ensure that the lead and bismuth liquid level in the main container is higher than The waste heat heat exchanger inlet window ensures the normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com