A permanent magnet bias magnetic circuit device suitable for giant magnetostrictive actuators

A technology of giant magnetostriction and permanent magnet bias, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, circuits, magnets, etc., can solve the problem of low magnetic field uniformity in the central rod area and the amount of permanent magnet materials Many, difficult to evenly distribute and other problems, to achieve the effect of increasing the magnetic potential, reducing the magnetic flux leakage effect, and miniaturizing the structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

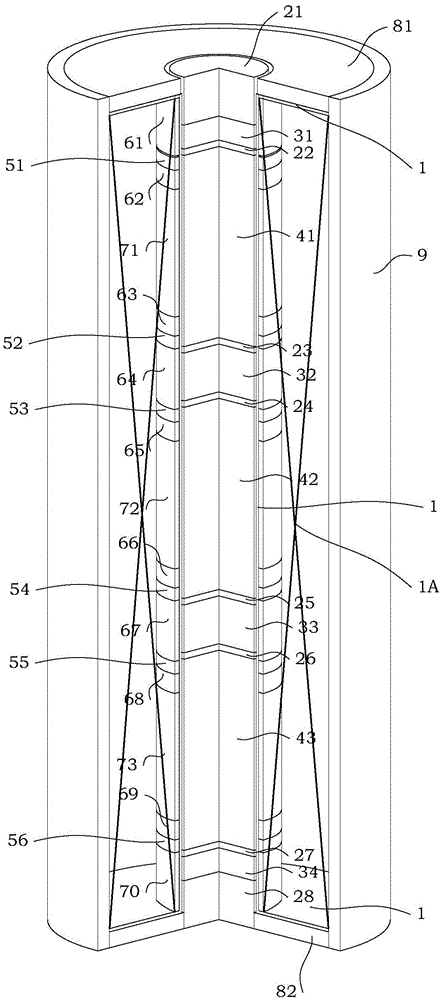

[0071]Ansys6.0 is used to simulate and measure the average magnetic field strength of the magnetostrictive rod: the central component is placed in the through hole of the coil cylinder, the intermediate component is sleeved on the coil cylinder, the enameled wire is wound on the intermediate component, and the magnetic permeable cylinder is 9 liang Install the first magnetic yoke 81 and the second magnetic yoke 82 on the end. The AA magnetic conduction column 21 in the center component is an active output terminal. The upper end of the permanent magnet column is an N pole, and the lower end is an S pole. The remanence of the permanent magnet column, permanent magnet ring and permanent magnet cylinder is 1.4 tesla.

[0072] (A) The magnetostrictive rod (AA magnetostrictive rod 41, AB magnetostrictive rod 42, AC magnetostrictive rod 43) has a diameter of 30 mm and a height of 60 mm.

[0073] (B) The diameter of the AB magnetically permeable column 22, the AC magnetically perme...

Embodiment 2

[0082] Ansys6.0 is used to simulate and measure the average magnetic field strength of the magnetostrictive rod: the central component is placed in the through hole of the coil cylinder, the intermediate component is sleeved on the coil cylinder, the enameled wire is wound on the intermediate component, and the magnetic permeable cylinder is 9 liang Install the first magnetic yoke 81 and the second magnetic yoke 82 on the end. The AA magnetic conduction column 21 in the center component is an active output terminal. The upper end of the permanent magnet column is an N pole, and the lower end is an S pole. The residual magnetism of the permanent magnet column, permanent magnet ring and permanent magnet cylinder is 1.0 Tesla.

[0083] Under the same parameters as in Example 1, except that the height change of the permanent magnet ring is 4 mm, the height change of the permanent magnet cylinder is 20 mm, BB mounting ring 62, BC mounting ring 63, BE mounting ring 65, BF mounting ...

Embodiment 3

[0086] Ansys6.0 is used to simulate and measure the average magnetic field strength of the magnetostrictive rod: the central component is placed in the through hole of the coil cylinder, the intermediate component is sleeved on the coil cylinder, the enameled wire is wound on the intermediate component, and the magnetic permeable cylinder is 9 liang Install the first magnetic yoke 81 and the second magnetic yoke 82 on the end. The AA magnetic conduction column 21 in the center component is an active output terminal. The upper end of the permanent magnet column is an N pole, and the lower end is an S pole. The remanence of the permanent magnet column, permanent magnet ring and permanent magnet cylinder is 0.4 Tesla.

[0087] Under the same parameters as in Example 1, except that the height change of the permanent magnet ring is 2 mm, the height change of the permanent magnet cylinder is 14 mm, BB mounting ring 62, BC mounting ring 63, BE mounting ring 65, and BF mounting ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com