Jelly gel and making method thereof

A technology of jelly gel and production method, which is applied in the direction of food preparation, food ingredients as gelling agent, food ingredients as antioxidant, etc., to achieve the effect of ensuring texture and appearance and enhancing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

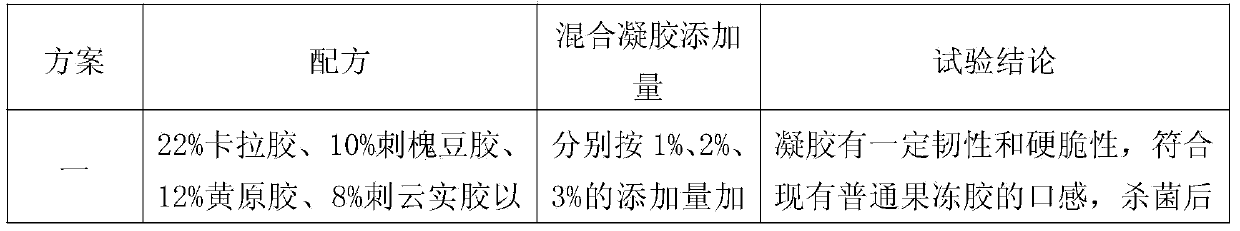

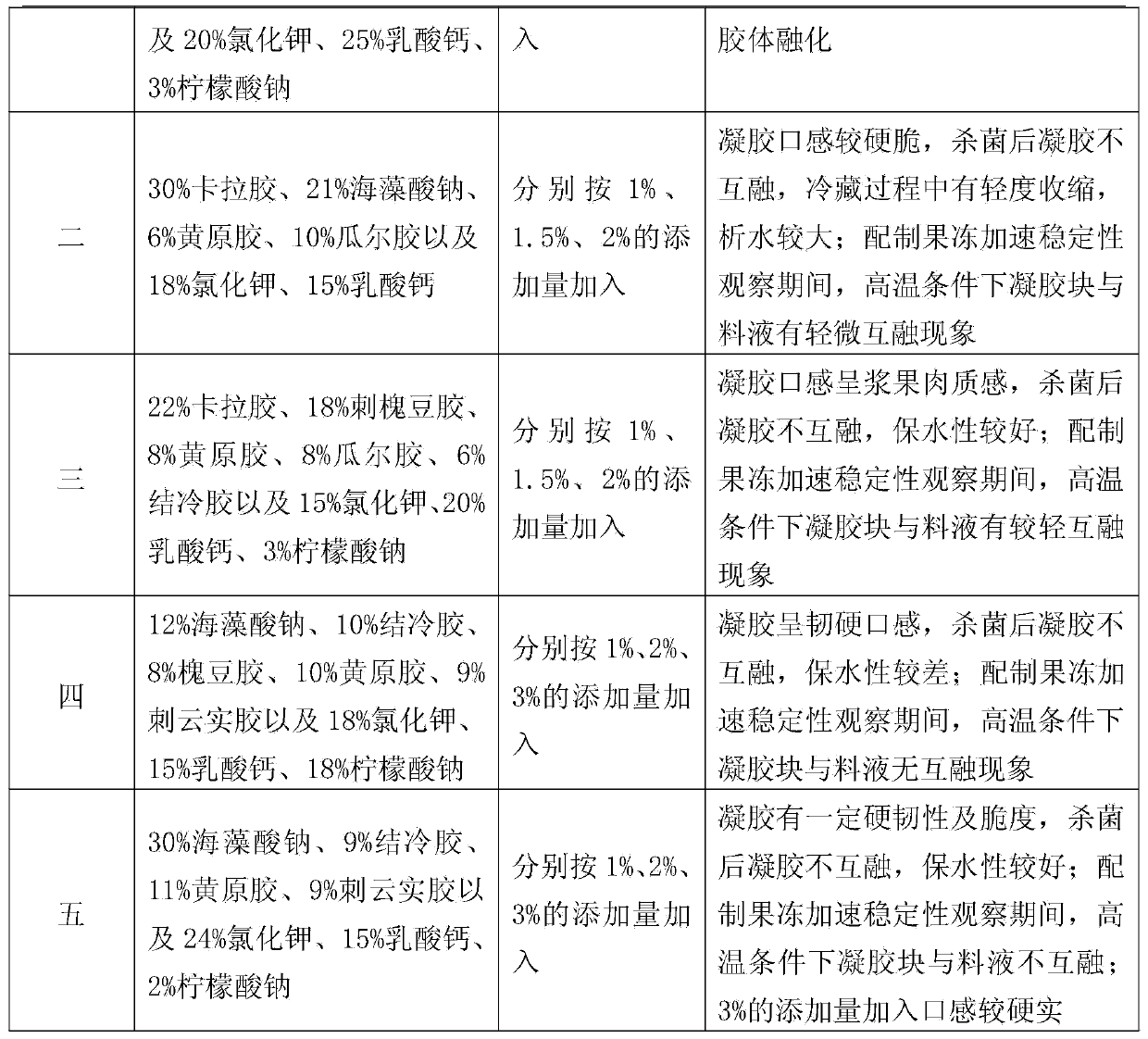

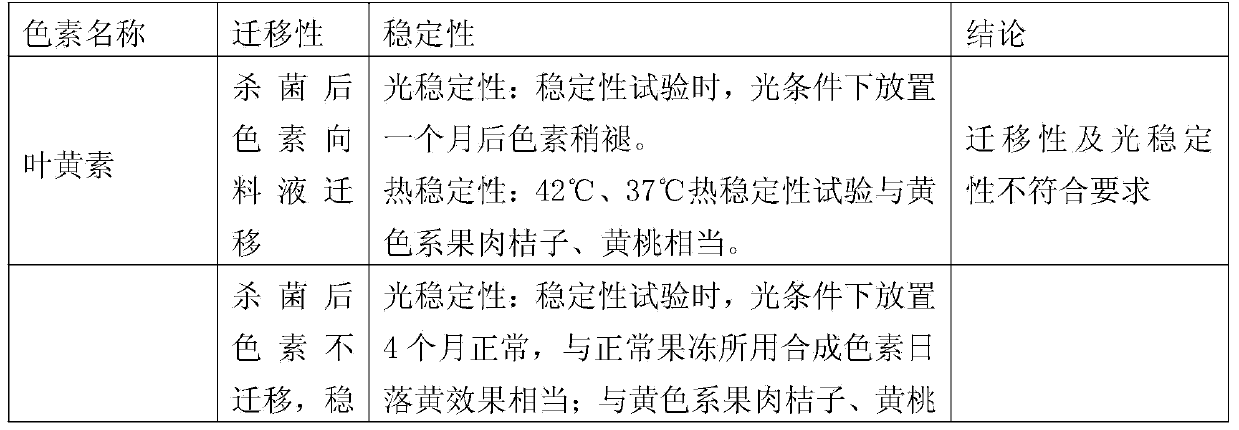

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 8-15 parts of white sugar in 10-20 parts of fructose syrup to make a mixed syrup; stir the mixed syrup and 60-65 parts of process water in a cooking tank to heat up, when the temperature reaches 75-85°C, add Stir 1-2 parts of mixed gel until dissolved, continue to stir and heat up to 96-100°C, and filter with a 120-mesh filter after stirring for 5 minutes; when the temperature of the filtered material liquid drops to 85°C, add 5-10 parts of flavor agent, heat and stir at 75-85°C for 10 minutes; dissolve 0.005-0.01 part of cochineal in warm water at 40-60°C (the weight of warm water is twice the weight of carmine), and add it to the cooking tank at 75-85°C for heat preservation and stirring Uniform; dissolve 0.75 parts of antioxidants in warm water at 40-60 ° C (the weight of warm water is twice the weight of antioxidants), add to the cooking tank at 75-85 ° C to keep warm and stir evenly; mix 0.1-0.15 parts of essence, 0.3 parts of citric acid After dissolving ...

Embodiment 2

[0031] Dissolve 8 parts of white sugar in 10 parts of fructose syrup with a DE value of 42 to make a mixed syrup; stir the mixed syrup and 60 parts of process water in a cooking tank to raise the temperature until the temperature reaches 75°C, then add 1 part of mixed Stir the gel until it dissolves, continue to stir and raise the temperature to 96°C, and then filter with a 120-mesh filter after stirring for 5 minutes; when the temperature of the filtered material liquid drops to 85°C, add 5 parts of fruit puree, stir evenly, and keep stirring at 75°C 10 minutes; Dissolve 0.005 parts of carmine with 0.01 parts of warm water at 40°C, add to the cooking tank at 85°C and keep stirring evenly; dissolve 0.75 parts of antioxidants with 1.5 parts of 40°C warm water, add to the cooking tank at 85°C and keep stirring Uniform; dissolve 0.1 parts of essence and 0.3 parts of citric acid in 0.8 parts of 40 ℃ warm water, add to the cooking tank at 85 ℃ and keep stirring evenly; Cool in wate...

Embodiment 3

[0034] Dissolve 15 parts of white sugar in 20 parts of fructose syrup with a DE value of 42 to make a mixed syrup; stir the mixed syrup and 65 parts of process water in a cooking tank to raise the temperature until the temperature reaches 85°C, and then add 2 parts of mixed Stir the gel until it dissolves, continue to stir and raise the temperature to 100°C, and then filter with a 120-mesh filter after stirring for 5 minutes; when the temperature of the filtered material liquid drops to 85°C, add 10 parts of jam, stir well, and then keep stirring at 85°C for 10 Minutes; Dissolve 0.01 part of cochineal in 0.02 parts of warm water at 60°C, add to the cooking pot at 85°C and keep stirring evenly; dissolve 0.75 parts of antioxidants in 1.5 parts of 60°C warm water, add to the cooking pot at 85°C and keep stirring evenly ; Dissolve 0.15 essence and 0.3 parts of citric acid in 0.9 parts of warm water at 60°C, add to the cooking tank at 85°C and keep stirring evenly; sterilize the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com