Aromatic tobacco curing method

A preparation method and oriental tobacco technology, applied in the field of tobacco agriculture, can solve the problems of blackening, complex aroma-causing substances, browning and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Test materials and methods

[0038] 1.1 Test location and species

[0039] Location: Namu Village, Fengping Town

[0040] Variety: Yunxiang Basma No. 1

[0041] 1.2 Materials to be tested: steel frame conditioning shed; drying facility (big furnace); smoke-piercing machine; temperature and humidity meter.

[0042] 1.3 Experimental design

[0043] 1.3.1 Requirements for tobacco leaves: Tobacco leaves have good maturity, all parts are in the middle leaves, and the consistency is good.

[0044] 1.3.2 Operation and management methods

[0045] Simulation shed: Open two small windows of 25cm×25cm at one end of the shed. Depending on the weather, uncover the two ends or two small windows of the shed to ensure that the average relative humidity in the shed is controlled at 70~80%, and the temperature is 27°C~37°C. Ensure that the tobacco leaves wither and turn yellow; after withering and turning yellow, heat up the drying facilities, open and close the shed intermittent...

Embodiment 2

[0063] 1. Test materials and methods

[0064] 1.1 Test location: Mandan Village, Lujiang Town; the tested variety is Yunxiang Basma No. 1.

[0065] 1.2 Experimental design: Four kinds of brewing sheds with different specifications were built as treatments for the experiment, and comparative experiments were carried out.

[0066] A. The specifications of the modulation shed are: middle height 1.6m, side height 0.8m, width 3m, length 6m; (the modulation shed used in the original production of CK) (one set with third gear, 1m / level)

[0067] B. The specifications of the modulation booth are: middle height 1.6m, side height 0.8m, width 3.3m, length 6m; (one set with third gear, 1.1m / level)

[0068] C. The specifications of the modulation booth are: middle height 1.8m, side height 1.2m, width 2m, length 6m; (two sets, second gear, 1m / level)

[0069] D. The specifications of the modulation booth are: middle height 2.4m, side height 1.8m, width 2m, length 6m; (three second gear, 1m...

Embodiment 3

[0094] 1 Test (demonstration) materials and methods

[0095] 1.1 Test location: Mandan Point of Lujiang Town, Longtan Point of Kasi Town

[0096] 1.2 Experimental design: A total of three batches (phases) of experiments were carried out. Among them, there are five treatments in the first stage, and four treatments in the second and third stages.

[0097] 1.3 Demonstration locations: Lujiang Mandan and Kasi Longtan respectively set up a site.

[0098] 1.4 Demonstration design:

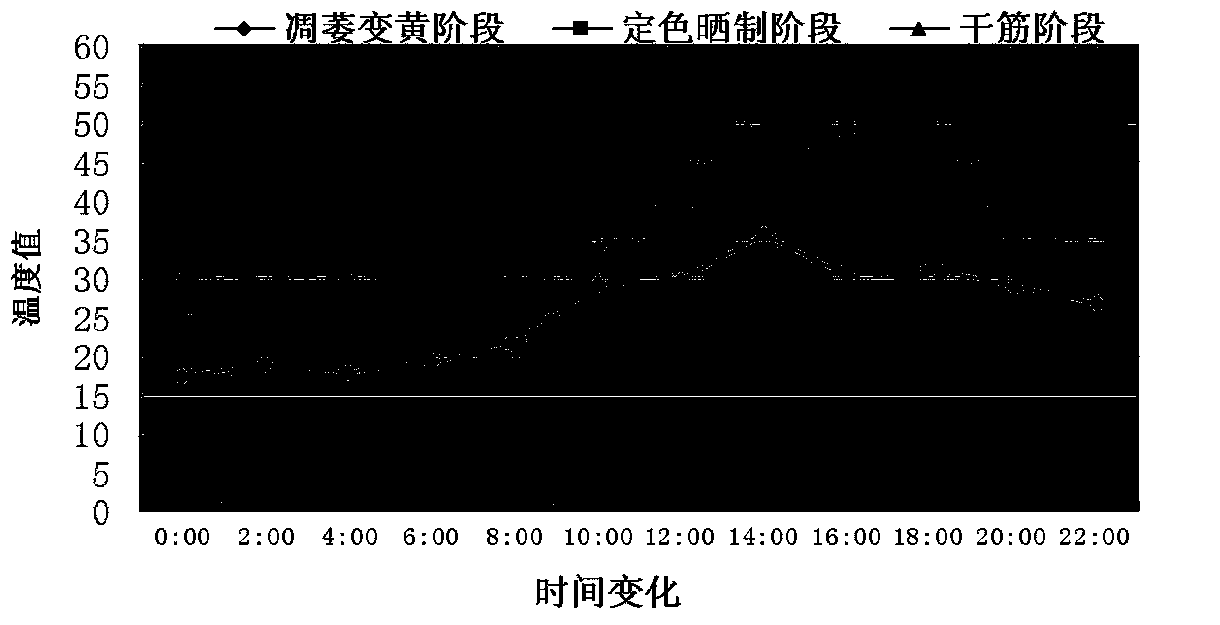

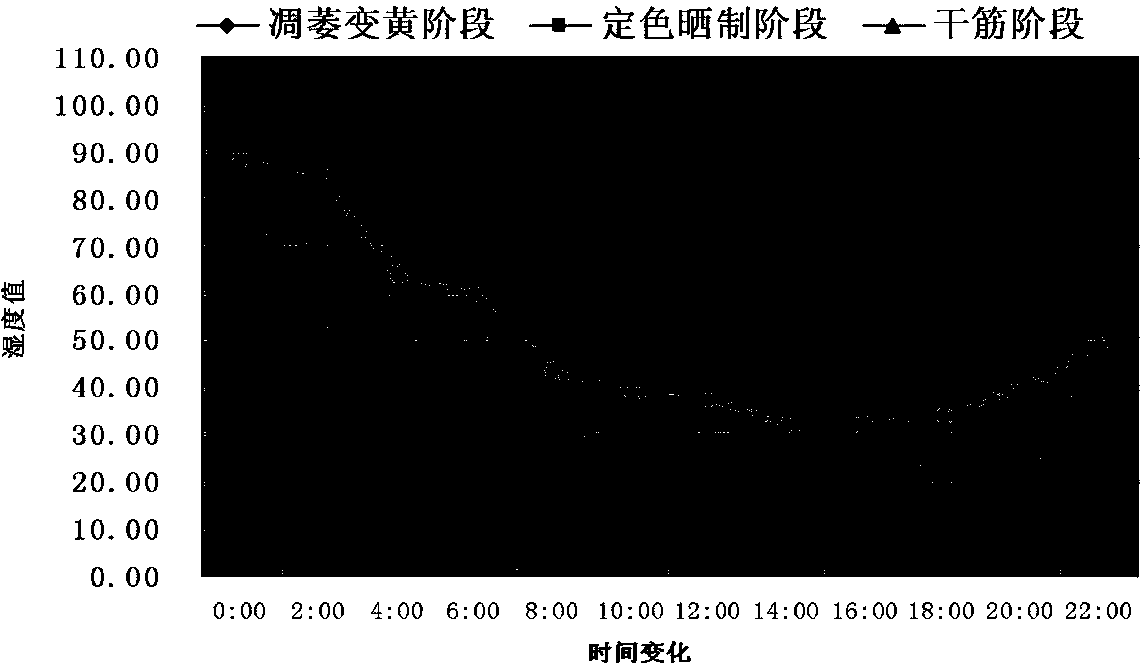

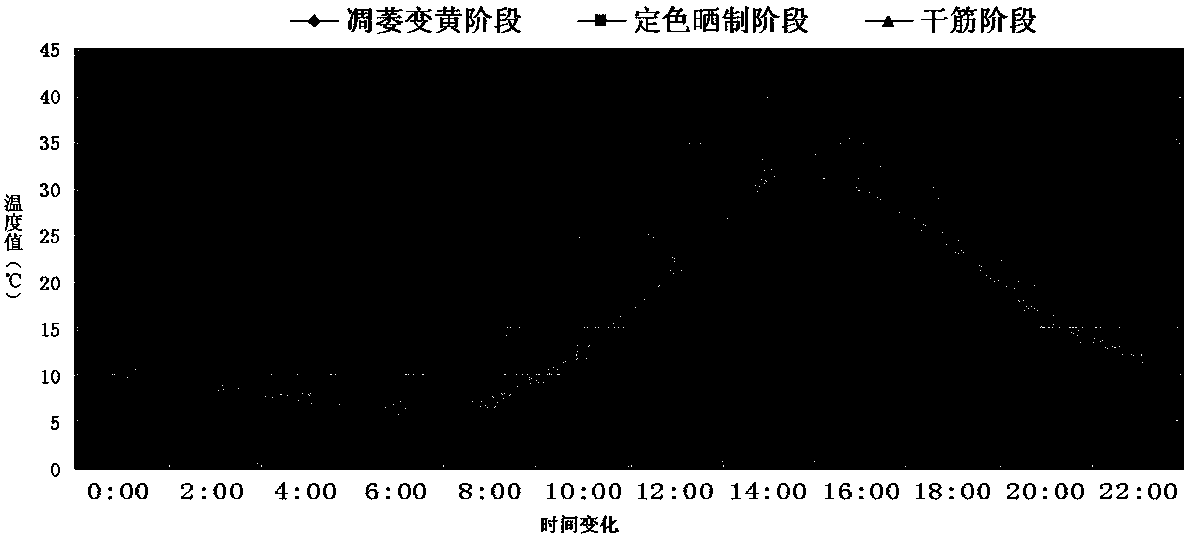

[0099] Withering and yellowing: the required temperature is 28°C-40°C, the relative humidity is >70%, and the degree of yellowing reaches 50%. In the case of dry climate and strong light, new tobacco leaves should be covered with shading objects for 1-40°C. 5 days (the number of shaded days can be determined according to the degree of yellowing). Close the window at 17:00 in the evening and open the window at 11:00 in the morning for 1 to 7 days in the shed. Open one end on the 1st to 3rd day, and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com