Self-locking booster compliant end gripper for tandem living hinges

A technology of loose-leaf hinges and grippers, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of insufficient driving force, insufficient pressure, and large force ratio, and achieve reliable grasping and good force-increasing effects , good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below is working principle and working process of the present invention:

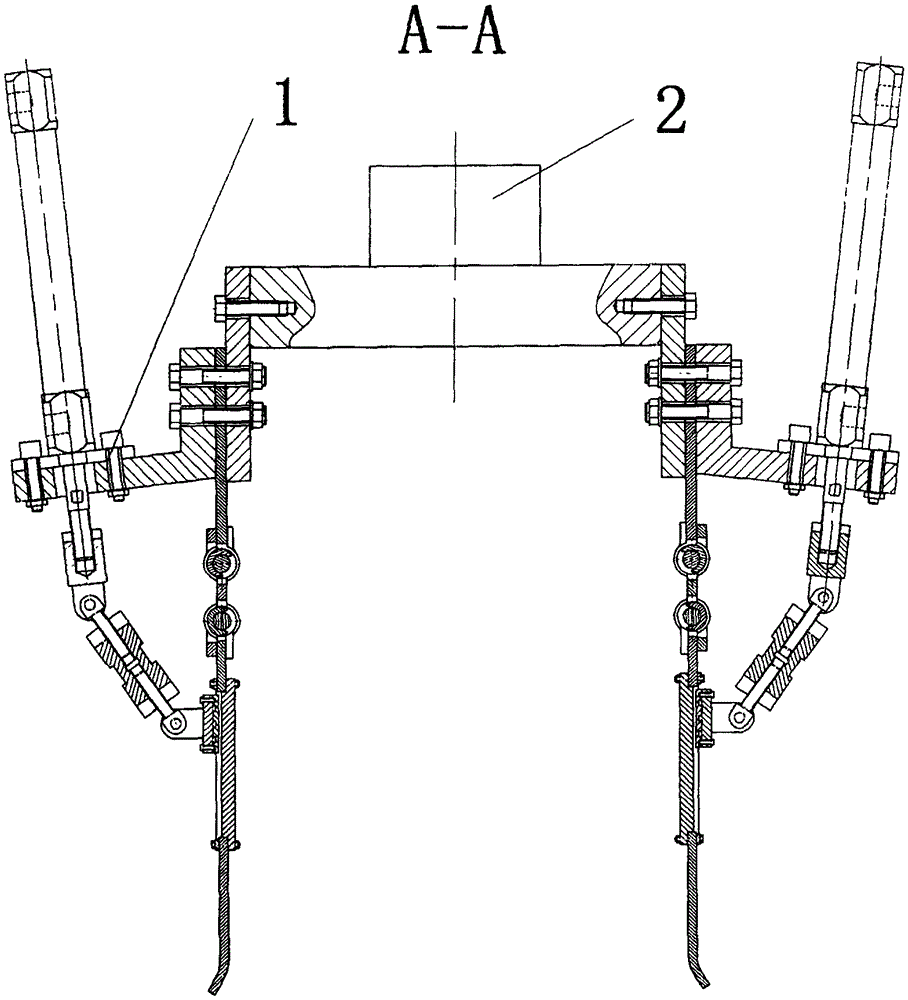

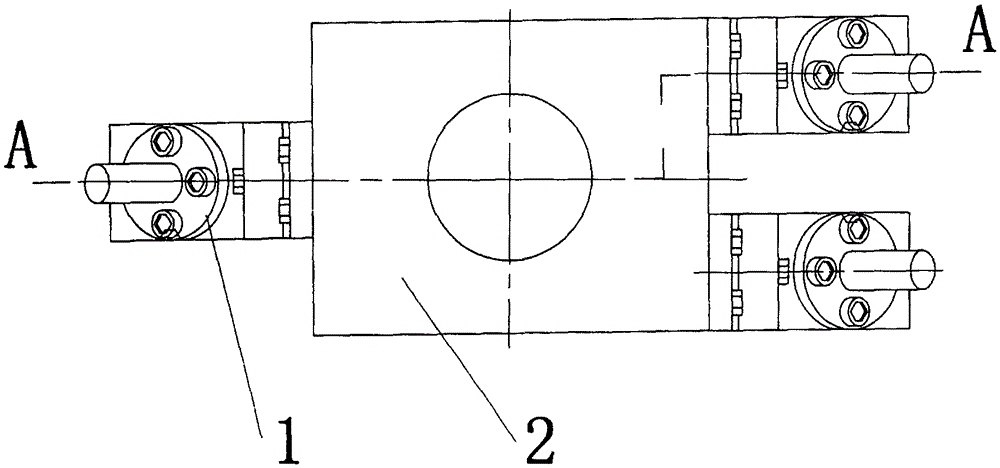

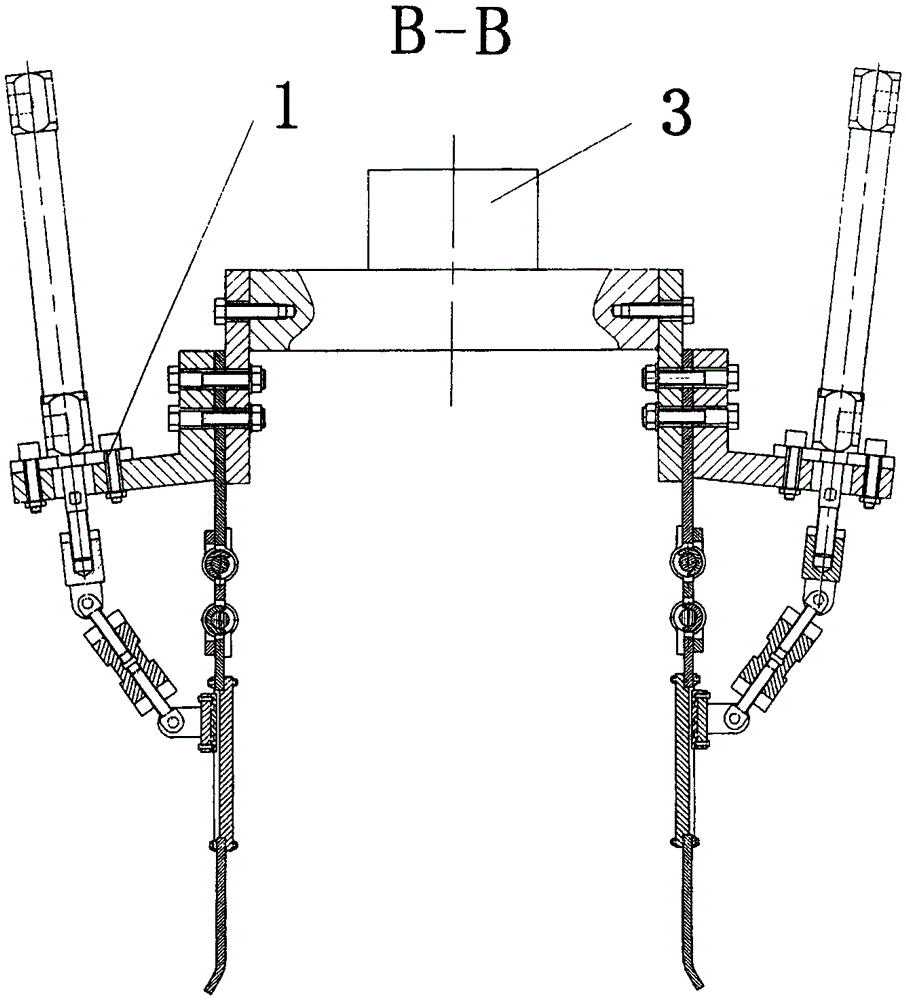

[0024] Such as figure 1 , 2 As shown, the research and analysis process: For long and rectangular complex objects, after theoretical analysis and experimental research, according to the range of shape, size and material of the grasped object, the safe range of grasping contact force is determined, and the design is optimized. Structural dimensions, two leaf spring characteristic parameters and pre-tightening angle determine the size of the palm, and adjust the length of the two power levers (left threaded hinge lever 11a, threaded sleeve 12a, right threaded hinge lever 13a form).

[0025] The optimization goal is: when the required grasping contact force is reached, the air pressure in the inner guide cylinder 1a reaches the system pressure, and the final included angle exceeds the friction angle of the linear guide slider 8a on the linear guide chute 7a, resulting in self-locking, and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com