Antiskid natural fiber car foot mat and production method thereof

A technology of natural fibers and car floor mats, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc. It can solve the problems of no anti-slip effect and high price, and achieve good anti-slip effect, firm bonding, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

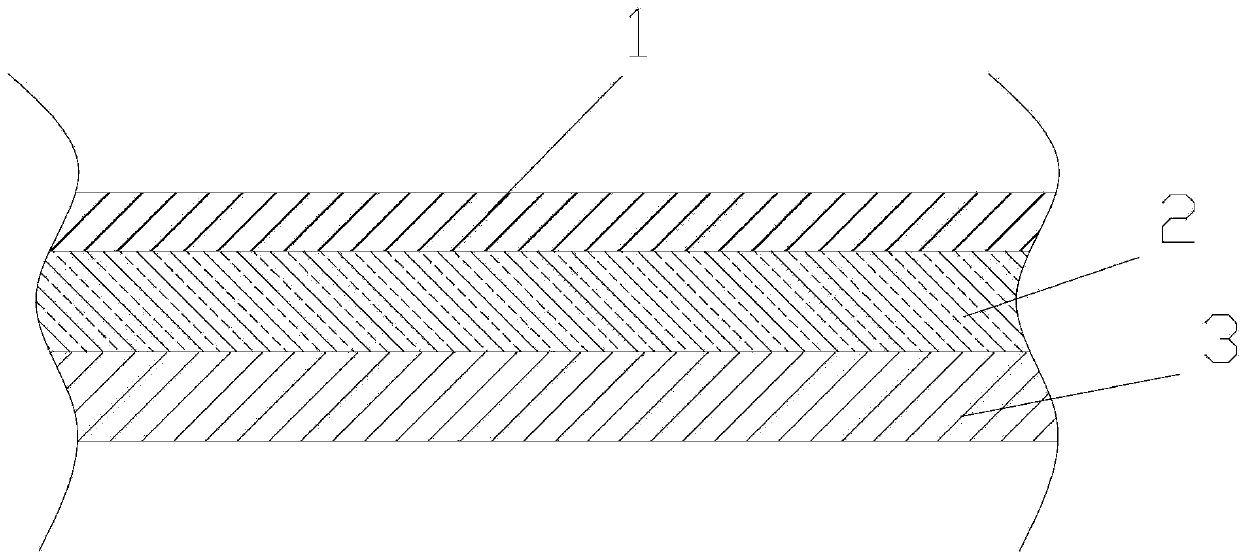

[0023] Such as figure 1 As shown, the anti-slip type natural fiber car floor mat described in this embodiment comprises a carpet surface 1 sisal fiber cloth layer, an intermediate layer 2 soundproof soft cotton layers, and the bottom layer 3 is silica gel; the soundproof soft cotton layer thickness is 3mm;

[0024] The silica gel is mainly composed of dimethylpolysiloxane rubber, fumed white carbon black, benzoyl peroxide paste and diphenylsilanediol.

[0025] In the anti-slip natural fiber car floor mat described in this embodiment, the bottom layer 3 is made of silica gel, which is soft and elastic, and has a very good anti-slip effect. As the bottom layer 3 of the foot pad, it can be well bonded to the inner wall of the car, and has electrical insulation performance and sealing performance, is odorless and tasteless, and will not cause peculiar smell in the small space of the car. It is easy to clean, and the dust on the silicone pad can be removed by washing directly wit...

Embodiment 2

[0030] The production method of the anti-skid type natural fiber car floor mat described in the present embodiment is to comprise the steps:

[0031] a. Use natural fiber yarn to weave natural fiber cloth on the loom;

[0032] b. Use a sewing machine to sew the natural fiber cloth and the sound-proof soft foam according to certain rules, and combine the two closely;

[0033] c. Carry out the gluing process on the back of the sound-proof soft foam after sewing; that is, the mass parts are 100 mass parts of dimethyl polysiloxane rubber, 60 mass parts of fumed silica, and benzoyl peroxide paste 1 part by mass and 5 parts by mass of diphenylsilanediol are mixed; then the natural fiber cloth and sound-insulating soft cotton are dried and dipped; then the compounded rubber is evenly coated with a calender The back of the sound-proof soft foam; then vulcanized, and placed at room temperature (23±2)°C for 24 hours, the gluing process is completed;

[0034] d. After the gluing is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com