System for rapidly lifting building blocks

A construction and rapid technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of lifting means other than building module units, reduce friction, etc., achieve simple and reliable connection, improve safety and efficiency, and facilitate coordination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

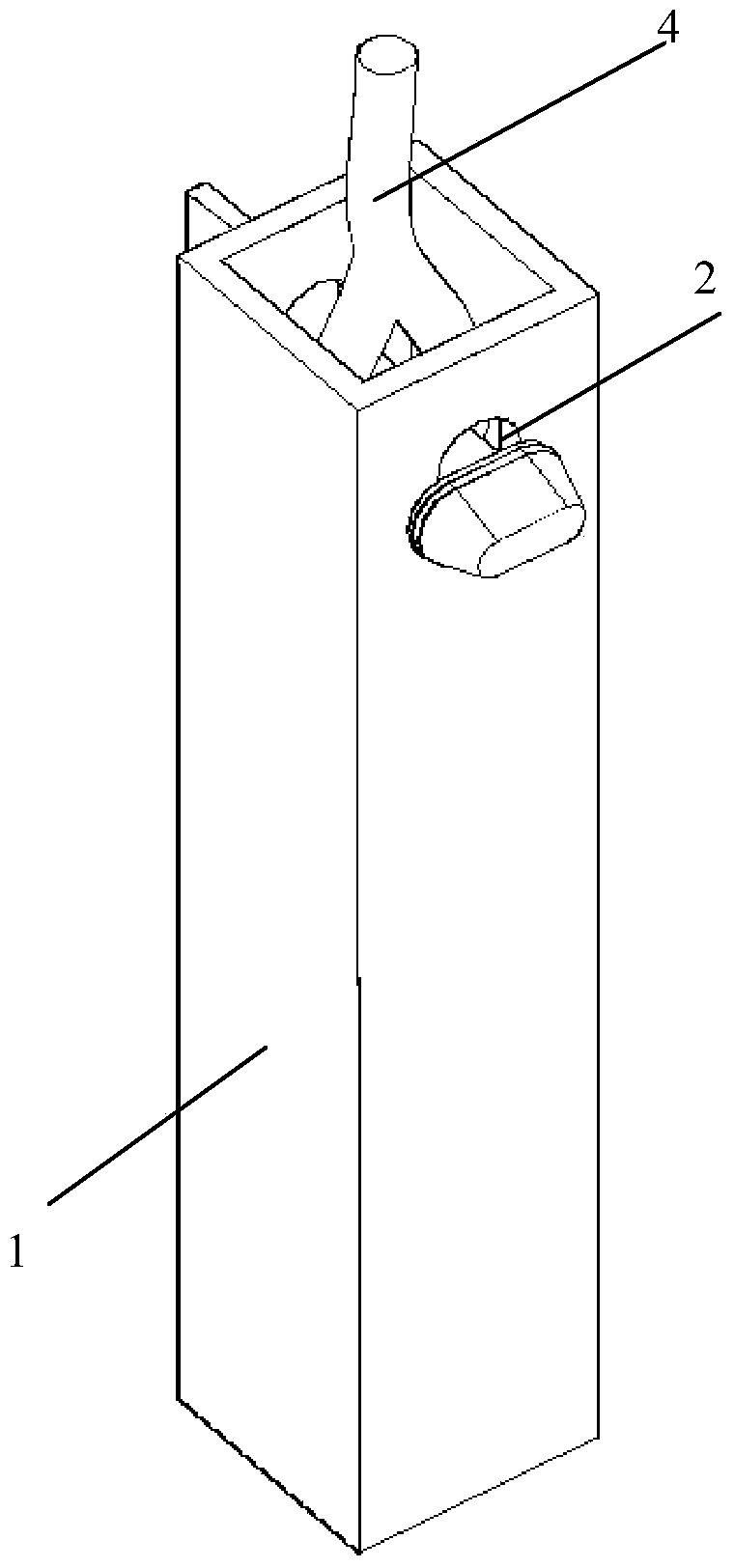

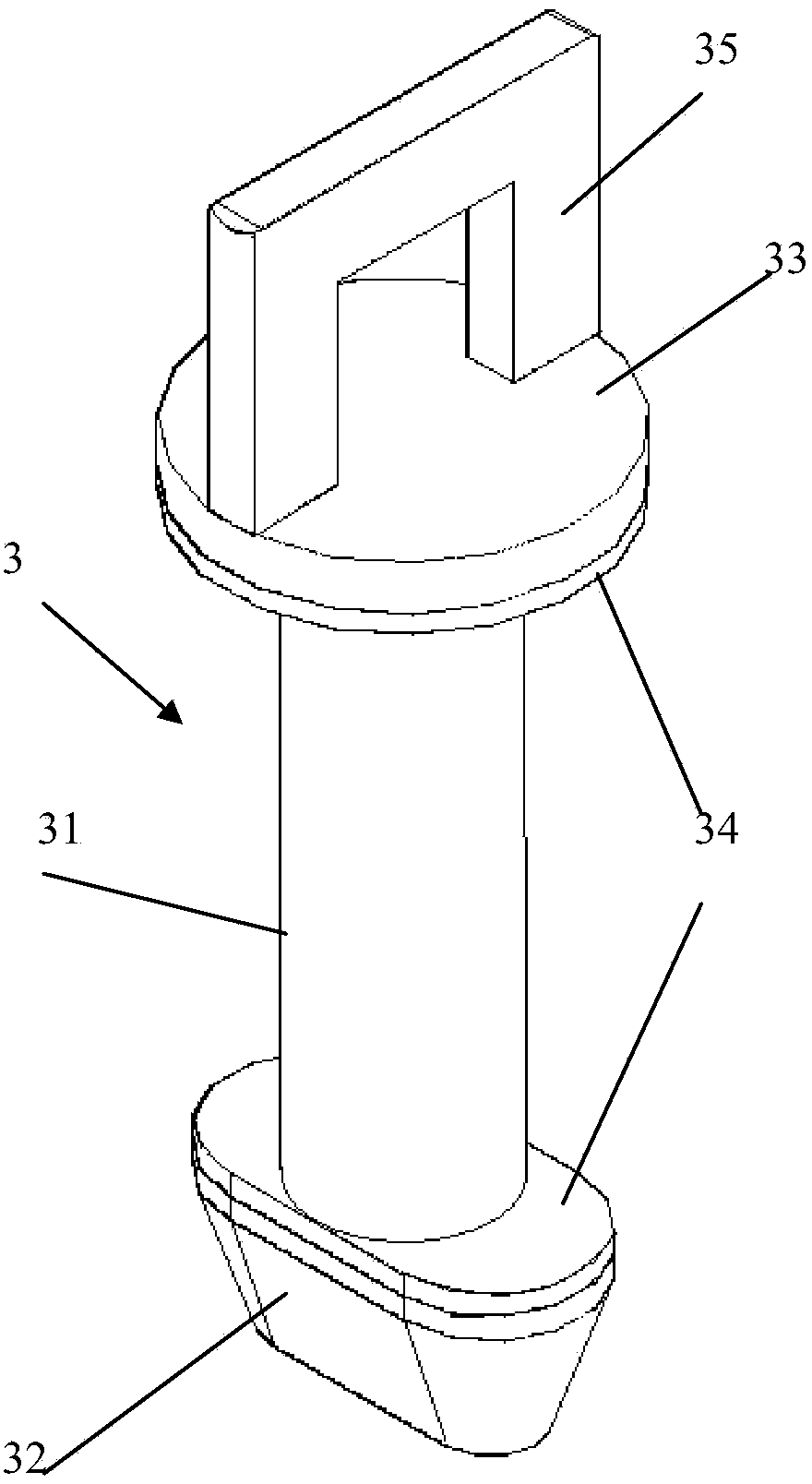

[0021] Such as figure 2 with image 3 As shown, the quick lifting system of the building module of the present invention includes a longitudinal hole 2 running through the end of the steel pipe 1 and a cast steel rotary self-locking latch 3, and the rotary self-locking latch includes a central circular shaft 31 1. The one-way fasteners 32 and the side baffles 33 respectively fixedly arranged at the two ends of the central axis, the one-way fasteners can pass through the two longitudinal holes of the steel pipe and insert the hoisting cable round buckle 4 inside the steel pipe After the one-way fastener passes through the longitudinal hole and rotates at a predetermined angle, it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com