Waterborne polyurethane polyamide resin emulsion for metal surface coating and preparation method thereof

A technology of polyurethane polyamide and polyamide resin, which is applied in the direction of polyurea/polyurethane coatings and coatings, and can solve the problems of environmental unfriendliness, hardness, solvent resistance, hydrolysis resistance, acid and alkali resistance, salt spray resistance, etc. High-end products are expensive and other issues, to achieve the effect of low cost of use and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation of embodiment 1-polyamide resin polyol

[0019] The preparation raw materials are: 40 grams of sebacic acid, 35 grams of adipic acid, 60 grams of dibasic acid, 15 grams of hexamethylenediamine, 10 grams of 1,2 cyclohexanediamine, 40 grams of isopropanolamine, 30 milliliters of pyrrolidone, and Triphenyl phosphate 0.5 g.

[0020] First add sebacic acid, dibasic acid and adipic acid into the reactor, then add hexamethylenediamine and 1,2 cyclohexanediamine at 140°C, react for 3h, then raise the temperature to 180°C, dehydrate for 30min, cool down to 130°C °C, add isopropanolamine and triphenyl phosphite at the same time, react for 3 hours, add solvent pyrrolidone during the reaction to control the reaction viscosity. Then raise the temperature for dehydration for 30 minutes, and when the dehydration is completed, raise the temperature to 200° C. and vacuumize at the same time to remove unreacted monomers and solvents. After 1 h, the reaction was complete...

Embodiment 2

[0021] The preparation of embodiment 2-polyamide resin polyol

[0022] The preparation raw materials are: 50 grams of sebacic acid, 40 grams of adipic acid, 70 grams of dibasic acid, 30 grams of hexamethylenediamine, 35 grams of isopropanolamine, 10 grams of ethanolamine, 40 milliliters of pyrrolidone, and 0.5 grams of triphenyl phosphite .

[0023] Add sebacic acid, dibasic acid and adipic acid to the reactor first, add hexamethylenediamine at 140°C, control the reaction temperature, react for 3 hours, raise the temperature to 180°C, dehydrate for 30min, cool down to 130°C, add isopropanolamine , ethanolamine and triphenyl phosphite, react for 3h, and control the reaction viscosity by adding pyrrolidone. Raise the temperature to 190°C for dehydration, then raise the temperature to 200°C after 30 minutes, vacuumize for 1 hour, the reaction ends, and the product is a light orange viscous liquid (molecular weight is about 2000).

Embodiment 3

[0024] The preparation of embodiment 3-metal surface coating waterborne polyurethane polyamide resin emulsion

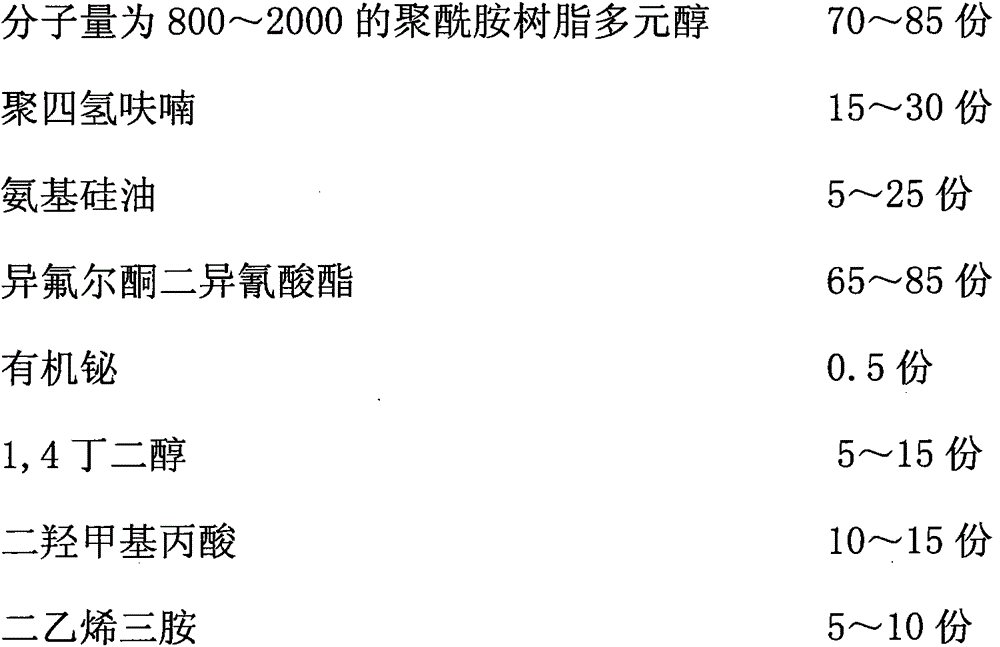

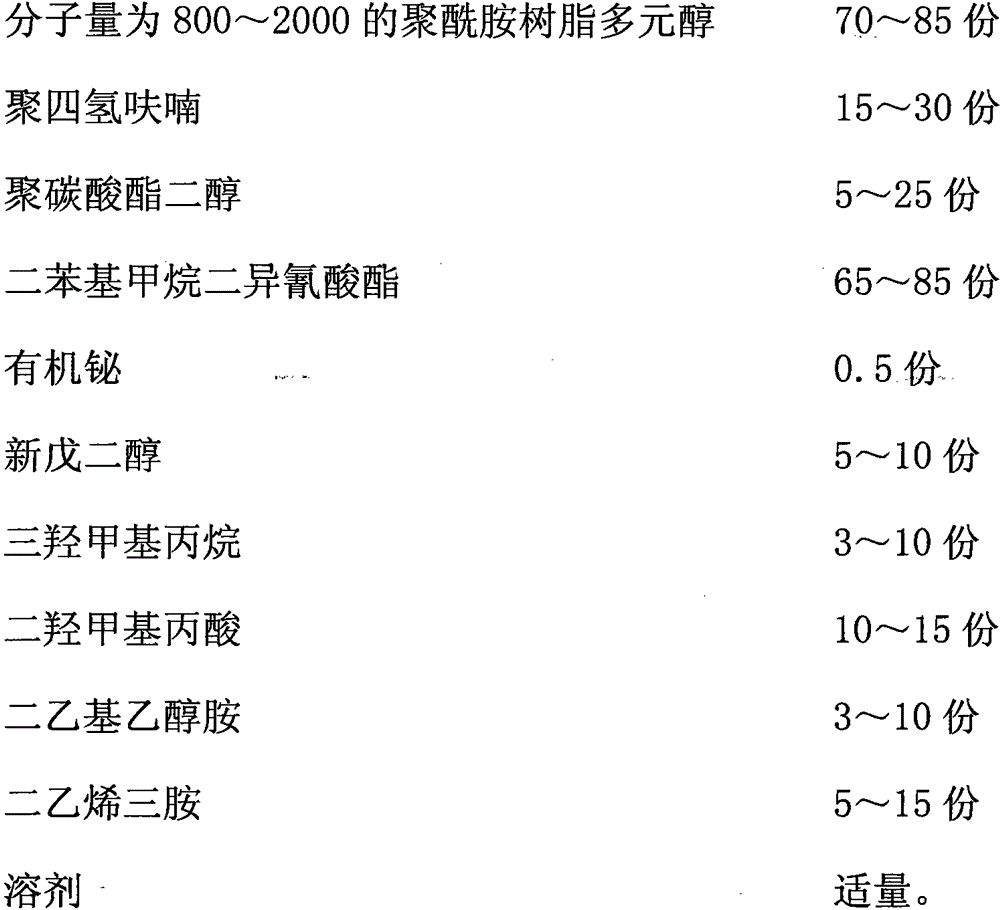

[0025] The preparation raw materials are: 75g of polyamide resin polyol prepared in Example 1, 20g of polytetrahydrofuran, 10g of amino silicone oil, 70g of isophorone diisocyanate, 0.5g of organic bismuth, 10g of 1,4-butanediol, dimethylolpropane 12g of acid, 8g of diethylenetriamine and an appropriate amount of solvent (to adjust the viscosity of the reaction system, such as pyrrolidone, etc.).

[0026] Mix polyamide resin polyol, polytetrahydrofuran, amino silicone oil, isophorone diisocyanate and organic bismuth and heat up to 80°C for 2 hours, then add 1,4 butanediol and dimethylol propionic acid for 4 hours During the reaction process, add solvent to control the viscosity, then cool to 45°C, emulsify, add diethylenetriamine to continue the reaction for 1 hour, and the obtained product is a light yellow translucent emulsion.

[0027] The metal surface coating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com